Produktkategorien

- Thermischer Schutzschalter 20

- Sicherungskastenhalter 36

- Temperatursensor 67

- Thermischer schalter 64

- Autosicherung 19

- Sicherungen festschrauben 7

- Thermosicherung 32

- oberflächenmontierte Sicherungen 12

- Thermistor 22

- Sicherungshalter für Leiterplattenmontage 27

- Kabelbaum 6

- Flachsicherungshalter 17

- Thermostat 46

- Elektro-Sicherung 14

Produkt Tags

5X20 mm 125 V/250 V Keramiksicherungen mit Blei, (3/16 Zoll X 3/4 Zoll)

5Auswahl und Anwendung von x20-mm-Keramiksicherungen: Bei den Sicherungstypen handelt es sich üblicherweise um Drahtsicherungen, Glassicherungsrohre, Quarzsandsicherungen, insert fuses, usw. The different forms have different usage environments.

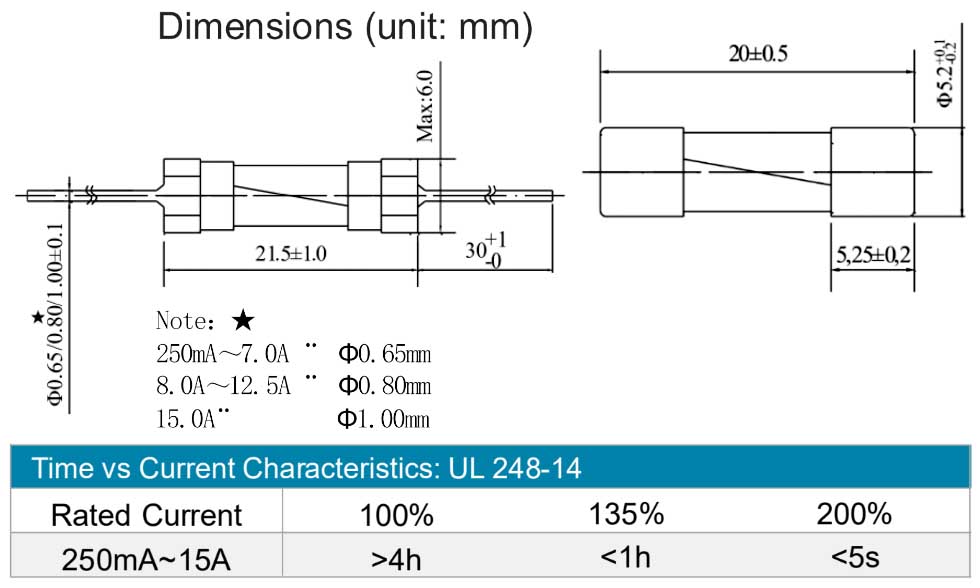

The rated current of 5x20mm fuses with different wire diameters is also different.

When selecting and adapting fuses, they will be affected by voltage and current, resulting in differences. From the voltage type: generally there are three types of high-voltage fuses, low-voltage fuses, and electronic circuit fuses. Differentiate from the current level: generally ranging from 0.5A to 100A.

Keramiksicherungen 5x20mm Kits – Superschnelle elektronische Komponenten |

Witonics 5x20mm 10A 250v Slow Blow Ceramic Fuses |

Bussmann 5x20mm Keramiksicherungen |

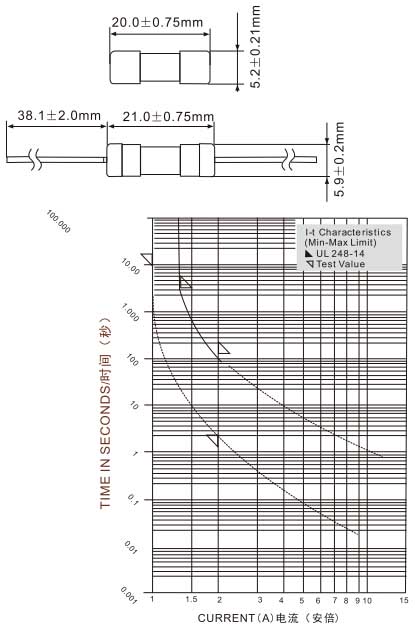

5x20mm ceramic tube fuse size chart

5X20mm Ceramic Tube Fuse Electrical Characteristics

In the process of selecting fuses, in addition to the above content, two types of overcurrent protection and overheating protection should be distinguished. Overcurrent protection: It is the most commonly used current limiting fuse. Overheating fuse: It plays a protective role when the temperature is too high. It is generally used in electrical appliances with heating and temperature control requirements. Zum Beispiel, Haartrockner, elektrische wasserkocher, elektrische Bügeleisen, thermal relays, usw.

The configuration of the fuse, its current size is the key measurement indicator of the protection function. Attention should be paid to the four current values of normal current (Nennstrom), fuse current, short-circuit current, and impact current. Its rated current is generally 1-1.2 times the current of the protected circuit.

| Breaking Capacity | Material | Betriebstemperatur | Soldering conditions |

| VDE:35A or 10ln whichever is greater(250mA-6.3A) UL:50 amperes at 125V/250V AC (250mA-10A) |

Fuse body –glass tube End cap –nickel plated brass Pigtail–tin plated copper on nickel plated brass cap |

-40℃~+125℃ | Wave solder:260℃,≤5S Hand solder: 360℃,≤1S |

Functional Characteristics

| Testing current | Blow Time | |

| Mindest | Max | |

| 150% | 1 Stunde | – |

| 210% | 100ms | 1800S |

| 275% | 10ms | 3S |

| 400% | 3ms | 300ms |

| 1000% | – | 20ms |

Approvals(○ Pending ● Approvals)

| Aktuelle Bewertung | Nennspannung | Norminal Melting I2T(A2sec) |

Zulassungen | ||||

| VDE | CQC | UL | PSE | KC | |||

| 250mA | 125V/250V | 0.14 | ● | ● | ● | ● | |

| 300mA | 125V/250V | 0.20 | ● | ||||

| 315mA | 125V/250V | 0.23 | ● | ● | ● | ● | |

| 350mA | 125V/250V | 0.27 | ● | ||||

| 400mA | 125V/250V | 0.38 | ● | ||||

| 500mA | 125V/250V | 0.50 | ● | ● | ● | ● | |

| 600mA | 125V/250V | 0.72 | ● | ||||

| 630mA | 125V/250V | 0.9 | ● | ● | ● | ● | |

| 750mA | 125V/250V | 1.2 | ● | ||||

| 800mA | 125V/250V | 1.6 | ● | ● | ● | ● | |

| 1A | 125V/250V | 2.4 | ● | ● | ● | ● | ● |

| 1.25A | 125V/250V | 3.5 | ● | ● | ● | ● | ● |

| 1.5A | 125V/250V | 4 | ● | ● | |||

| 1.6A | 125V/250V | 7.2 | ● | ● | ● | ● | ● |

| 2A | 125V/250V | 9.6 | ● | ● | ● | ● | ● |

| 2.5A | 125V/250V | 16 | ● | ● | ● | ● | ● |

| 3A | 125V/250V | 17.8 | ● | ● | |||

| 3.15A | 125V/250V | 22 | ● | ● | ● | ● | ● |

| 3.5A | 125V/250V | 28 | ● | ● | |||

| 4A | 125V/250V | 45 | ● | ● | ● | ● | ● |

| 5A | 125V/250V | 62 | ● | ● | ● | ● | ● |

| 6A | 125V/250V | 70 | ● | ||||

| 6.3A | 125V/250V | 72 | ● | ● | ● | ● | |

| 7A | 125V/250V | 88 | ● | ||||

| 8A | 125V/250V | 110 | ○ | ○ | ● | ○ | |

| 10A | 125V/250V | 144 | ○ | ○ | ● | ○ | |

Kontaktiere uns

Warten auf Ihre E-Mail, Wir werden Ihnen innerhalb von 24 Stunden antworten 12 Stunden mit wertvollen Informationen, die Sie brauchten.

English

English العربية

العربية Български

Български 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά Magyar

Magyar Italiano

Italiano 日本語

日本語 한국어

한국어 Polski

Polski Português

Português Română

Română Русский

Русский Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Tiếng Việt

Tiếng Việt