Categorías de Producto

- Disyuntor térmico 20

- Portafusibles 36

- Sensor de temperatura 67

- Interruptor térmico 64

- Fusible del coche 19

- Fusibles atornillados 7

- fusible térmico 32

- fusibles de montaje en superficie 12

- termistor 22

- Portafusibles de montaje en PCB 27

- Arnés de cableado 6

- Portafusibles de cuchilla 17

- termostato 46

- Fusible eléctrico 14

Etiquetas de productos

Mensajes recientes

Fabricantes de interruptores térmicos de China

¿Qué es un interruptor térmico??

El interruptor térmico se basa en el entorno de trabajo de los cambios de temperatura., Se produce deformación física dentro del producto., un elemento de control que se enciende o apaga automáticamente, También conocido como interruptor de control de temperatura., Protección térmica, Controlador de temperatura, etc.. Los métodos de control de temperatura más utilizados son:

At YaXun, we focus on customizing high quality Thermal switch supply. Interruptor de corte térmico (Disc Thermostat) is the electronics, electrical appliances industry's most common overheating protection, we can provide customized 50 a 100,000 different models of small batch production, as well as a wide range of product design and testing services to complete your project. Please contact our Thermal switch team to get a free quote, and talk about your next temperature control project design.

¿Qué es un interruptor térmico??

El interruptor térmico se basa en el entorno de trabajo de los cambios de temperatura., Se produce deformación física dentro del producto., un elemento de control que se enciende o apaga automáticamente, También conocido como interruptor de control de temperatura., Protección térmica, Controlador de temperatura, etc.. Los métodos de control de temperatura más utilizados son: Sudden jump Thermal switch, Liquid expansion Thermal switch, Pressure-type Thermal switch, Electronic Thermal switch. Customers in the selection of Thermal switch, need to determine the Thermal switch control mode, product size and installation methods, wire type and temperature requirements, after the temperature control material parameters of the design, Thermal switch through the internal structure of the assembly and packaging process, to form a complete Thermal switch device. From the production process to the completion of the test need more than a dozen processes.

Thermal switch Characteristics

Thermal switchs are ideal for your product thermal protection. The following are some of the advantages of the Thermal switch:

1. Intelligent automation control, buena estabilidad

2. abierto, stop the temperature difference is small

3. Different classification widely used, low prices

4. Control the temperature range, en -200 grados Celsius a 150 grados Celsius, -50 grados Celsius a 850 grados

5. Temperature test convenience: in the test furnace, Oil sink, water sink, Thermal switch sink equipment, testing on the spot.

6. The test results are automatically saved, and can not be artificially changed

7. Large overload current

8. Applies to the family (industry) of various electrical appliances, equipo electronico.

Jump Type Thermal switch

Jump type Thermal switch is a bimetallic sheet as a protective device for temperature sensing elements, the use of bimetal physical properties, the heat generated by the heat transfer to the bimetallic wafer, to set the action temperature set quickly action, automatic control contact open or closed; When the temperature drops to the reset temperature setting, the bimetal quickly returns to its original state, causing the contact to close or disconnect, to achieve the purpose of turning on or off the circuit, thereby controlling the circuit. Jump type Thermal switch is the most widely used thermal protection components, in order to facilitate product development and application.

Ya Xun developed a variety of temperature control methods, como: automatic reset type, manual reset type, normally open type, normally closed type, temperature limit type, car water tank thermal protection device, and installation of fixed diversification. There is always a can meet your requirements, please consult our professional technical team.

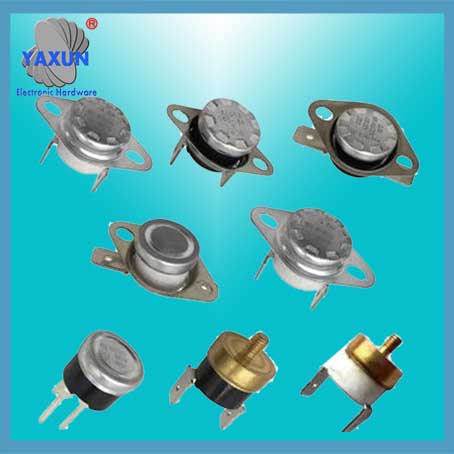

Bimetal Thermal switch has a lot of no classification, used in different electrical appliances, common models are: KSD301, KSD302, KSd9700, adjustable Thermal switch, defrost Thermal switch, electric iron Thermal switch, motor thermal protector and so on. Ya Xun has been working on the market development, with the world's smallest Thermal switch TB02, KW-C and so on.

In the complex thermal protection circuit, i also designed for your product multiple thermal protection, usually used in series with the thermal fuse, Jump type Thermal switch as a level of protection. The thermal fuse is used as a secondary protection function to effectively prevent the burnout of the heating element and effectively prevent the fire accident when the sudden failure of the heating element is caused by the function of the sudden jump Thermal switch.

Liquid Expansion Thermal switch

Liquid expansion Thermal switch also called capillary Thermal switchs, widely used boiler, horno electrico, high-power electrical appliances, and so on. When the temperature of the heating element changes, the temperature inside the temperature control part of the material (generalmente líquido) to produce the corresponding thermal expansion and contraction of the physical phenomena (volume changes), and the membrane box communicating with the temperature sensing portion is expanded or contracted.

To the principle of leverage, drive switch on | off operation, can achieve the purpose of constant temperature.

Liquid expansion Thermal switch has a manual reset and the auto reset function.

Pressure Type Thermal switch

Pressure-type Thermal switch through the sealed internal temperature components: temperature wrap and capillaries, the temperature change of the heating element is changed to the change of the space pressure or the volume, by the elastic member and the instantaneous fast mechanism, automatically close the contact to achieve the purpose of automatic control of the temperature.

The main components from the Department of temperature (sonda), temperature setting main body, the implementation of open and close the micro switch or automatic damper composed of three parts. Pressure Thermal switch for refrigeration equipment (such as refrigerators, congeladores, aire acondicionado, etc.) and heating appliances.

In Ya Xun, to meet the needs of the market, the main products are: GTLH Thermal switch,

Prodigy mechanical Thermal switch, Ranco Thermal switch, S Series Saginomiya Thermal switch, ROBERTSHAW Thermal switch, Danfoss Thermal switch.

Electronic Digital Thermal switch

Digital electronic temperature controller (resistive) is the use of resistance temperature method to measure, is a high precision temperature detection controller, can quantify the temperature digital control.

Generally use NTC | PTC thermal sensor or thermocouple as a temperature detection element, its principle is: the NTC | PTC thermistor or thermocouple designed to the corresponding circuit, CNT | PTC thermistor or thermocouple changes with temperature, it will produce the corresponding voltage and current changes, and then through the microcontroller to change the voltage and current to detect, quantify the display, and do the appropriate control. Digital temperature controller with high accuracy, good sensitivity, intuitive, easy to operate and so on.

Quick Proofing

Are you hurrying to find new Thermal switchs with different parameters to develop new products? Ya Xun unique quick proofing processing methods, only need to process half of the traditional product production cycle, to meet your different product needs. but this advanced processing methods also have some limitations, please check here to see if the quick proofing is available for your next item.

Material Identification And Quality Assurance

Ya Xun introduced a full range of measurement and testing equipment, to ensure that all incoming quality, we have a modern measurement laboratory to ensure that your product quality, can really meet the specific parameters of each product requirements.

Thermal switch Test Standard

Production of high-quality temperature control accessories, depends on the production management and process control. And technology and advanced testing equipment is the guarantee of product quality. To ensure product quality, Yaxun insists that each project follows the following steps.

Technical Support: Consult the entire technical team to provide you with free production design and (DFM) recommendations

Keep its promise: plant manager will conduct a thorough review of each order, to ensure compliance with the contract requirements

Real material: all incoming to be tested

Process control: complete production process inspection, including random sampling (FAI)

Flawless factory: finished product inspection and quality report

We guarantee that all products have passed my company's various testing standards.

You're Ready For Your Next Project Yet?

After receiving your product parameters, Ya Xun's professionals will analyze the feasibility of product design. our engineers will judge the correctness of temperature control, combined with the appropriate temperature control application principle, to ensure that your next project can reach or exceed your expectations. Get a free quote.

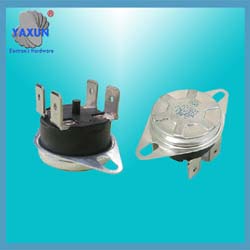

Protector contra sobrecalentamiento KSD302

Compressor temperature control switch

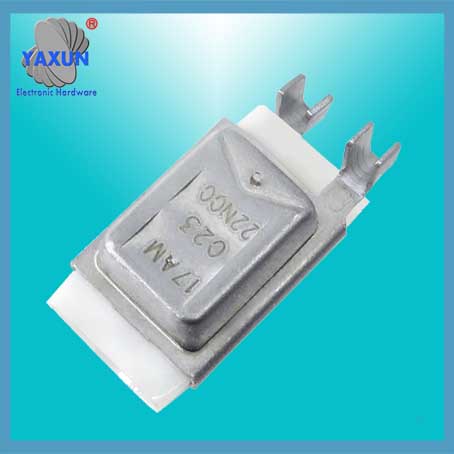

17Protector de motor AM

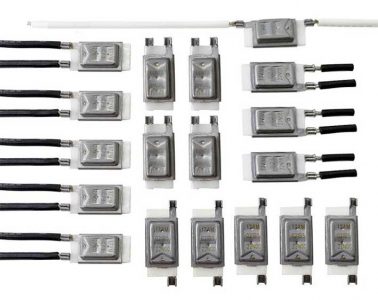

thermal switch with cable

Manual reset bimetallic thermostat

Refrigerator Bimetal Defrost Thermostat

Micro thermal switch with cable

Contáctenos

Esperando tu email, le responderemos dentro de 12 horas con la valiosa información que necesitabas.

English

English العربية

العربية Български

Български 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά Magyar

Magyar Italiano

Italiano 日本語

日本語 한국어

한국어 Polski

Polski Português

Português Română

Română Русский

Русский Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Tiếng Việt

Tiếng Việt