Categorías de Producto

- Disyuntor térmico 20

- Portafusibles 36

- Sensor de temperatura 67

- Interruptor térmico 64

- Fusible del coche 19

- Fusibles atornillados 7

- fusible térmico 32

- fusibles de montaje en superficie 12

- termistor 22

- Portafusibles de montaje en PCB 27

- Arnés de cableado 6

- Portafusibles de cuchilla 17

- termostato 46

- Fusible eléctrico 14

Etiquetas de productos

Mensajes recientes

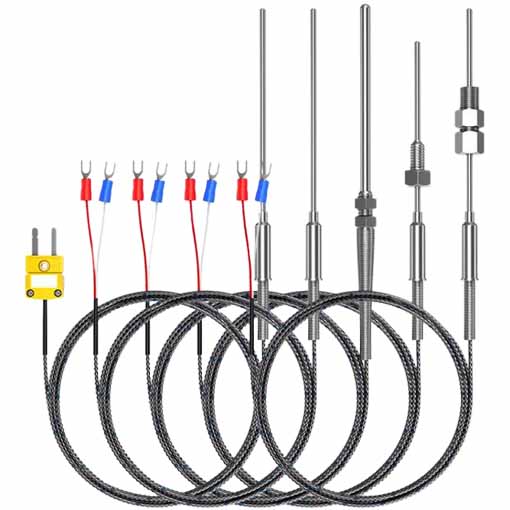

Proveedor de termopares de precisión

El E original fabricado en fábrica., j, El sensor de termopar T se utiliza para la siguiente detección de temperatura: termómetro, calentador de agua, hogar, horno, circuito, IDT, unión fría, horno, multímetro, digital, industrial.

El principio de funcionamiento de la e, j, Termocoza t sensor :

Cuando hay dos conductores o semiconductores A y B formando un bucle, los dos extremos están conectados entre sí, Mientras las temperaturas en las dos uniones sean diferentes. La temperatura en un extremo es t, Llamado al final de trabajo o en el extremo caliente, y la temperatura en el otro extremo es t0, llamado el extremo libre (también llamado final de referencia) o extremo frío. Se generará una fuerza electromotriz en el bucle. La dirección y la magnitud de la fuerza electromotriz están relacionadas con el material del conductor y la temperatura de las dos uniones. Este fenómeno se llama “efecto termoeléctrico”, y el bucle compuesto por dos conductores se llama “par termoeléctrico”. Estos dos conductores se llaman “termoelectrodos”, y la fuerza electromotriz generada se llama “fuerza termoelectromotora”.

La fuerza termoelectromotora consta de dos partes de la fuerza electromotriz, Una parte es la fuerza electromotriz de contacto de dos conductores, y la otra parte es la fuerza termoelectromotora de un solo conductor.

El tamaño de la fuerza termoelectromotora en la E, j, T Termocouple Sensor Loop solo está relacionado con la temperatura del material del conductor y las dos uniones que conforman el termopar, y no tiene nada que ver con la forma y el tamaño del sensor de termopar. Cuando se fijan los dos materiales de electrodo del sensor de termopar, La fuerza termoelectromotora es la diferencia de la función de las dos temperatura de unión T y T0.

que es:

Esta relación se ha utilizado ampliamente en la medición de la temperatura real.. Porque la unión fría t0 es constante, la fuerza termoelectromotora generada por la E, j, T termopar solo cambia con la temperatura de la unión caliente (fin de la medición), eso es, Una cierta fuerza termoelectromotiva corresponde a una cierta temperatura. Podemos lograr el propósito de la medición de la temperatura siempre que usemos el método para medir la fuerza termoelectromotora.

El principio básico de la medición de la temperatura del termopar es que dos conductores de diferentes componentes forman un circuito cerrado. Cuando hay un gradiente de temperatura en ambos extremos, Habrá corriente pasando por el bucle. En este momento, Hay una fuerza electromotriz-termoelectromotora entre los dos extremos, ¿Cuál es el llamado efecto Seebeck. Dos conductores homogéneos con diferentes componentes son los termoelectrodos, El final con una temperatura más alta es el final de funcionamiento, El final con una temperatura más baja es el extremo libre, y el extremo libre generalmente está a cierta temperatura constante. De acuerdo con la relación funcional entre la fuerza termoelectromotora y la temperatura, Se realiza una tabla de índice de termopar;

La tabla de índice se obtiene cuando la temperatura del extremo libre es de 0 ℃, y diferentes sensores de termopares tienen diferentes tablas de índice.

Cuando el tercer material metálico está conectado en el circuito de termopar, Mientras la temperatura de las dos uniones del material sea la misma, El potencial termoeléctrico generado por el termopar permanecerá sin cambios. Eso es, No se ve afectado por el acceso del tercer metal en el bucle. Por lo tanto, Cuando el termopar mide la temperatura, el instrumento de medición se puede conectar, y la temperatura del medio medido se puede conocer después de mide la fuerza termoelectromotora. Cuando el termopar mide la temperatura, la temperatura de su unión fría (El extremo de medición es el extremo caliente, y el extremo conectado al circuito de medición a través del cable se llama la unión fría) se requiere para mantener la misma temperatura. Su potencial termoeléctrico es proporcional a la temperatura medida. Si el (ambiente) La temperatura de la unión fría cambia durante la medición, afectará seriamente la precisión de la medición. Tome ciertas medidas para compensar en la unión fría, y la influencia causada por el cambio de temperatura de la unión fría se llama la compensación de la unión fría del termopar es normal. Cable de compensación dedicado para la conexión con instrumento de medición.

Método de cálculo de la compensación de la unión fría del sensor de termopar:

De milivoltio a temperatura: Mida la temperatura de la unión fría, Conviertalo al valor de milivoltio correspondiente, Agréguelo al valor milivoltio del termopar, y calcular la temperatura;

De temperatura a milivoltio: Mida la temperatura real de la temperatura del extremo frío, respectivamente, En términos de milivoltios, Después de restar los valores derivados de MV, Para obtener la temperatura.

El E original fabricado en fábrica., j, El sensor de termopar T se utiliza para la siguiente detección de temperatura: termómetro, calentador de agua, hogar, horno, circuito, IDT, unión fría, horno, multímetro, digital, industrial.

Termopar blindado de 3 mm de diámetro. + Toma tipo J

PT100 E, j, T sonda del sensor de temperatura

Cambio de detección de temperatura de termopar de corredor caliente

Termopar de alta temperatura de tipo K

Contáctenos

Esperando tu email, le responderemos dentro de 12 horas con la valiosa información que necesitabas.

English

English العربية

العربية Български

Български 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά Magyar

Magyar Italiano

Italiano 日本語

日本語 한국어

한국어 Polski

Polski Português

Português Română

Română Русский

Русский Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Tiếng Việt

Tiếng Việt