catégories de produits

- Disjoncteur thermique 20

- Porte-boîte à fusibles 36

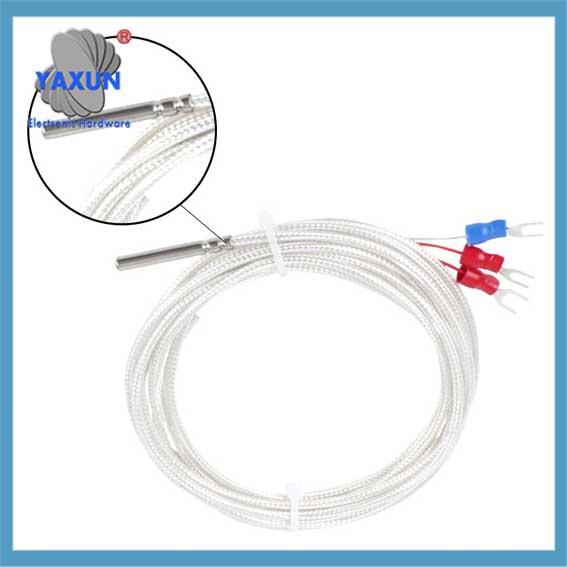

- Capteur de température 67

- Interrupteur thermique 64

- Fusible de voiture 19

- Fusibles boulonnés 7

- fusion thermique 32

- fusibles à montage en surface 12

- thermistance 22

- Porte-fusible à montage sur circuit imprimé 27

- Faisceau de câblage 6

- Porte-fusibles à lame 17

- thermostat 46

- Fusible électrique 14

Mots clés du produit

Messages récents

CTN, CTP, PT100, DS18B20 pour capteurs de sonde de température

Sonde thermocouple: Il utilise l'effet thermoélectrique pour mesurer la température, et présente les caractéristiques d'une large plage de mesure et d'une vitesse de réponse rapide.

Sonde à résistance thermique: utilise la propriété selon laquelle la résistance des matériaux métalliques ou semi-conducteurs change avec la température pour mesurer la température, et présente les caractéristiques d'une précision de mesure élevée et d'une bonne stabilité.

Sonde semi-conductrice: utilise la propriété selon laquelle la conductivité des matériaux semi-conducteurs change avec la température pour mesurer la température, et a les caractéristiques de petite taille, poids léger et faible consommation d'énergie.

CTN, CTP, PT100, Les sondes de température DS18B20 et les capteurs de température jouent un rôle important dans le domaine de la mesure de la température. Ce qui suit est une introduction détaillée aux capteurs de sonde de température:

Il existe de nombreux types de capteurs de température, y compris:

Thermocouples

Ces capteurs sont faits de deux métaux différents qui se connectent à deux points pour former une jonction. Ils sont fiables, précis, et peut fonctionner sur une large gamme de températures.

Détecteurs de température de résistance (RTD)

Ces capteurs sont basés sur le changement de résistance d'un métal à mesure que la température change.

Thermistances

Ces capteurs utilisent les caractéristiques de température des résistances semi-conductrices, qui changent la résistance à mesure que la température change. Les thermistances sont sensibles et ont une grande précision par rapport à leur coût.

Coefficient de température négatif (CTN) thermistances

Ces capteurs sont sensibles et peuvent répondre à de très faibles changements de température. Ils ont une plage de température de -50 ° C à 250 °C.

Détecteurs de température résistive

Ces capteurs ont des coefficients de température positifs (CTP) et offrir des mesures de température précises. Cependant, Ils ont une mauvaise sensibilité.

1. Définition et principe de travail

sonde de température:

Définition: Une sonde de température est un dispositif spécifiquement utilisé pour mesurer la température, et son composant central est un élément sensible à la température.

Principe de travail: Une sonde de température utilise des éléments sensibles (comme les thermocouples, résistances thermiques, semi-conducteurs, etc.) Pour convertir les changements de température en signaux électriques pour le traitement ou l'affichage des circuits ultérieurs.

Capteur de température:

Définition: Un capteur de température est un concept plus large qui comprend une sonde de température et un circuit de traitement du signal qui lui est connecté.

Principe de travail: Un capteur de température ne comprend pas seulement un élément sensible, mais a également un circuit de traitement du signal qui peut terminer l'acquisition, Traitement et sortie des signaux de température, généralement sous forme de signaux numériques ou analogiques.

2. Types et caractéristiques

Type de sonde de température:

Sonde thermocouple: Il utilise l'effet thermoélectrique pour mesurer la température, et présente les caractéristiques d'une large plage de mesure et d'une vitesse de réponse rapide.

Sonde à résistance thermique: utilise la propriété selon laquelle la résistance des matériaux métalliques ou semi-conducteurs change avec la température pour mesurer la température, et présente les caractéristiques d'une précision de mesure élevée et d'une bonne stabilité.

Sonde semi-conductrice: utilise la propriété selon laquelle la conductivité des matériaux semi-conducteurs change avec la température pour mesurer la température, et a les caractéristiques de petite taille, poids léger et faible consommation d'énergie.

Type de capteur de température:

Capteur de température analogique: Sorte signaux analogiques, qui doivent être convertis en signaux numériques par des convertisseurs analogiques-numériques pour un traitement ultérieur.

Capteur de température numérique: Sorte directement des signaux numériques, a une forte capacité anti-ingérence, grande précision, et est facile à intégrer dans le système de contrôle.

Capteur de température intelligent: a l'auto-diagnostic, auto-étalibration, Communication et autres fonctions, et peut réaliser une surveillance et un contrôle à distance.

3. Sélection et application

Facteurs de sélection:

Environnement d'application: Déterminez si l'environnement mesuré a des conditions spéciales telles que la corrosivité, température élevée, haute pression, etc., afin de sélectionner des matériaux et des niveaux de protection appropriés.

Plage de mesure: Sélectionnez un capteur approprié en fonction de la plage de la température à mesurer pour vous assurer que le capteur peut mesurer avec précision dans la plage requise.

Exigences de précision: Selon les exigences de précision de l'application de mesure de la température, Sélectionnez un capteur avec une précision correspondante.

Budget des coûts: Sous la prémisse de garantir la performance, Considérez les facteurs de coût et choisissez des capteurs rentables.

Rares d'application:

Automatisation industrielle: utilisé pour surveiller les changements de température dans les équipements industriels, Machines et processus de production pour assurer le fonctionnement normal de l'équipement et de la qualité du produit.

Industrie médicale: Utilisé dans l'équipement médical, Instruments de surveillance de la température et équipement de stockage de médicaments pour surveiller la température du patient, Température ambiante et conditions de stockage de médicaments.

Industrie automobile: Utilisé dans les moteurs de véhicules électriques, condensateurs, Convertisseurs DC, systèmes de charge, ainsi que les moteurs automobiles, boîtes de vitesses, Systèmes de climatisation et systèmes d'échappement pour surveiller et contrôler la température de divers liquides et gaz.

Industrie de l'agriculture et de la transformation des aliments: utilisé dans les serres agricoles, rangement froid, Équipement de transformation des aliments et véhicules de transport pour surveiller et contrôler la température des produits agricoles et des aliments.

Autres champs: comme l'industrie de la climatisation et de la réfrigération, industrie militaire et aérospatiale, Industrie de l'Internet des objets, etc.. sont également largement utilisés.

Iv. Utilisation et maintenance

installation: Installez le capteur correctement en fonction des instructions d'installation pour assurer un bon contact entre le capteur et l'objet à mesurer et éviter les erreurs de mesure causées par une mauvaise installation.

Wiring: Connectez correctement la ligne de signal et la ligne électrique du capteur pour assurer la stabilité et la précision de la transmission du signal.

étalonnage: Calibrez régulièrement le capteur pour s'assurer que sa précision de mesure répond aux exigences de la demande. Le processus d'étalonnage implique généralement de placer le capteur dans un environnement de température connu, Comparaison de la différence entre sa valeur de sortie et la valeur standard, et faire des ajustements nécessaires.

entretien: Nettoyer et maintenir le capteur régulièrement pour éviter la poussière, saleté, etc.. qui affectent les performances de mesure du capteur. En même temps, Faites attention pour vérifier si la connexion par câble est lâche ou endommagée, et remplacer les pièces endommagées dans le temps.

En résumé, Les capteurs de sonde de température ont une large gamme d'applications et une position importante dans le domaine de la mesure de la température. Lorsque vous les sélectionnez et les utilisez, Il est nécessaire de faire des considérations complètes en fonction des scénarios d'application et des exigences spécifiques pour garantir la précision et la fiabilité des résultats de mesure. Si vous avez d'autres questions ou si vous avez besoin d'aide supplémentaire, N'hésitez pas à me le faire savoir.

Contactez-nous

En attente de votre email, nous vous répondrons dans les 12 heures avec des informations précieuses dont vous aviez besoin.

English

English العربية

العربية Български

Български 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά Magyar

Magyar Italiano

Italiano 日本語

日本語 한국어

한국어 Polski

Polski Português

Português Română

Română Русский

Русский Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Tiếng Việt

Tiếng Việt