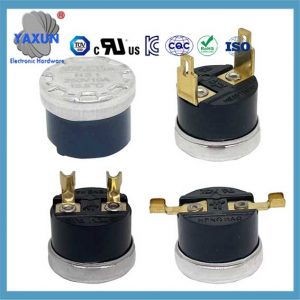

L'interruttore di interruzione del disco termico bimetallico personalizzato in Cina è dotato di montaggio superficiale e installazione plug-in PCB. Interruttore di interruzione del circuito di surriscaldamento (termostato bimetallico) sono dispositivi progettati per mantenere i componenti al sicuro in situazioni in cui si verifica una temperatura eccessiva. Elenco delle specifiche dei prodotti selezionati per interruttori termici e protettori termici a montaggio superficiale, schede tecniche, produttori & fornitori.

Gli interruttori termici a disco bimetallici a montaggio superficiale sono componenti indispensabili per il funzionamento sicuro ed efficiente di motori/apparecchi elettrici. Prevenendo il surriscaldamento, proteggono gli apparecchi elettrici dai danni, prolungarne la vita operativa, ridurre il rischio di pericoli di incendio, garantire un funzionamento sicuro, e ridurre al minimo i tempi di inattività e i costi di manutenzione. Inoltre, L'interruttore termico a disco bimetallico aiuta a rispettare gli standard di sicurezza del settore, garantendo tranquillità agli operatori e alle parti interessate. Con l’avanzare della tecnologia, l'interruttore termico continua ad evolversi, offrendo una protezione più precisa e affidabile per i motori in un'ampia gamma di applicazioni.

Con lo sviluppo della tecnologia, la gamma di applicazioni del motore è sempre più ampia, soprattutto l'uso del motore nella vita quotidiana e nella produzione è sempre più importante. Ma accade anche l'incidente del motore, nella vita reale, la bruciatura del motore è causata principalmente dal successivo surriscaldamento della bobina bloccata, il carico è eccessivo, sovraccarico del motore, mancanza di fase e altri motivi. L'installazione di un protettore termico è uno dei modi efficaci per proteggere il motore. interruttore termico, chiamato anche interruttore termico, interruttore di controllo della temperatura, ecc. È una sorta di interruttore termico con lamiera bimetallica come elemento sensibile alla temperatura, quando l'apparecchio elettrico funziona normalmente, la lamiera bimetallica è allo stato libero, il contatto è in uno stato disconnesso, quando la temperatura sale al valore della temperatura di azione, l'elemento bimetallico viene riscaldato per produrre stress interno e azione rapida, aprire il contatto, interrompere/collegare il circuito, in modo da svolgere un ruolo di interruttore termico bimetallico. Attendere finché la temperatura ambiente non scende alla temperatura impostata della protezione, il contatto richiuderà il circuito collegato, e il motore funzionerà di nuovo.

Scegliere l'interruttore termico giusto

Come scegliere il giusto interruttore a disco bimetallico del circuito Off è molto importante, altrimenti non solo non può svolgere un ruolo protettivo, ma farà sì che il motore non possa funzionare a causa della selezione errata, o addirittura bruciare.

1. Voltaggio & Determinazione attuale

• L'interruttore termico a disco bimetallico ha diversi intervalli di tensione 400 V 380 V 230 V 220 V 110 V, Anche i motori CC avranno 36 V 24 V 12 V, ecc., in base alle diverse tensioni di lavoro per scegliere diversi protettori di tensione nominale, in linea di principio, la tensione di applicazione effettiva è inferiore o uguale alla tensione nominale del protettore, Per esempio, 380Il motore V non può scegliere la protezione della tensione nominale 220 V, e la protezione con tensione nominale di 220 V può essere utilizzata nel motore da 110 V;

• La corrente dei motori degli elettrodomestici è divisa in tre tipi di corrente di avviamento, corrente di funzionamento normale e corrente bloccata, la corrente nominale del protettore dovrebbe essere maggiore del valore massimo delle tre correnti, e devi lasciare un margine. Per esempio, un motore corrente di lavoro normale 1A, corrente di avviamento 1,5 A, corrente di blocco 2A, allora la corrente nominale del protettore selezionato è almeno 2A, ed è meglio scegliere la corrente nominale di 3 A o 5 A per mantenere il margine. Una parte della corrente di avviamento del motore è maggiore della corrente nominale della protezione, ma l'orario di inizio è più breve, e la corrente di funzionamento normale e la corrente di blocco sono inferiori alla corrente nominale del protettore, in questo caso, puoi anche scegliere questo protettore. Perché la corrente di avviamento è maggiore della corrente nominale, ma a causa del poco tempo, l'effetto termico della corrente non ha avuto il tempo di riscaldare il doppio pezzo portando alla protezione del protettore, in modo da non causare errori.

2. Scegliere di commutare termicamente la temperatura

• La scelta della temperatura dell'interruttore termico è legata a tre fattori: livello di isolamento del filo smaltato, posizione di installazione e tipo di protezione.

La temperatura dell'interruttore termico è inferiore alla temperatura massima consentita, Per esempio, la temperatura massima della classe F è 155 ℃, e la selezione effettiva può essere 145℃ o 150℃.

•La posizione di installazione è divisa in integrato all'interno della batteria e raggruppato all'esterno della batteria, perché quando il motore è bloccato e inoltra calore, il fenomeno del surriscaldamento si diffonde dall'interno e dall'esterno. Se il protettore è sepolto all'interno, la temperatura dell'interruttore termico è leggermente inferiore alla temperatura massima del filo smaltato; Se è legato all'esterno della bobina, considerare la differenza di temperatura tra interno ed esterno, e scegli un dispositivo di protezione dalla temperatura più bassa. Per esempio, il livello di isolamento è filo smaltato di classe F, bobina all'interno e all'esterno con una differenza di temperatura di 20 ℃, quindi scegliere 155-20=135℃ circa del protettore;

Il protettore del motore ha funzioni di protezione come il sovraccarico, mancanza di fase, squilibrio, sottocarico, messa a terra/dispersione, e stallo. Può formare un'unità di protezione del controllo motore con componenti elettrici come contattori e avviatori motore. Ha funzioni come il controllo automatico remoto, controllo diretto in loco, indicazione del pannello, segnale di allarme, e comunicazione del bus di campo.

3. Selezione della durata dell'interruttore termico

I diversi tempi di prova del blocco del motore, i diversi requisiti per la durata della protezione non sono gli stessi, come il normale blocco del motore domestico 18 giorni, il numero di cicli di ripristino dell'azione normale non verrà superato 100000 volte, la durata della tensione nominale è superiore a 100000 i tempi possono essere selezionati protettore; Solo alcuni motori delle pompe lo fanno 3 giorni di blocco, in linea di principio, il requisito di vita è centinaia di volte.

4. Selezione dell'interruttore termico per le prestazioni di tenuta

La bobina del motore nel processo dell'interruttore termico immergerà la vernice per migliorare le prestazioni di isolamento del processo, la vernice a immersione è divisa in vernice a goccia, immersione, aspirare nella vernice e in altri processi, soprattutto il vuoto nella pressione della vernice è elevato, la vernice isolante entra facilmente all'interno della protezione, con conseguente fallimento del protettore. La serie ST01 di An Electronics ha una tenuta molto elevata, sotto la condizione di -0.08deputato, il tasso di immersione della vernice può raggiungere 3%; In caso di -0.03deputato, il tasso di verniciatura può raggiungere meno di uno su diecimila.

Parametri del protettore del motore

| Parametri tecnici

Alimentazione ausiliaria |

Indicatori tecnici | |||

| ARD2(l) | ARD2F | ARD3 | ||

| Alimentazione ausiliaria | Voltaggio | CA 85 V ~ 265 V/CC 100 V ~ 350 V | ||

| Voltaggio | ≤7VA | ≤15 VA | ||

| Tensione di lavoro nominale | AC380V/AC660V,50Hz/60 Hz | |||

| Corrente operativa nominale | 1A(0,1~9999) | |||

| 5A(0,1~9999) | ||||

| 1.6A(0,4A~1,6A) | ||||

| 6.3A(1,6A~6,3A) | ||||

| 25A(6,3A~25A) | ||||

| 100A(25A~100A) | ||||

| 250A(63A~250A) | ||||

| 800A(250A~800A) | ||||

| Capacità dei contatti di uscita del relè | CA 250 V/3 A;CC 30 V/3 A | CA 250 V/6 A | ||

| Cambia ingresso | 2-modo | 9-modo | ||

| Ambiente | Temperatura di lavoro: -10°C~55°C | |||

| Temperatura di conservazione: -20°C~65°C | ||||

| Umidità relativa: 5﹪~95﹪ senza condensa | ||||

| Altitudine: ≤ 2000 metri | ||||

| Livello di inquinamento | 2 | |||

| Livello di protezione | IP20 | Unità principale IP20 Unità display IP45 | ||

| Categoria di installazione | Livello III | |||

Salvamotore bimetallico

| Parametri tecnici | Indicatori tecnici | ||

| Alimentazione ausiliaria ARD3T | CA/CC 110 / 220V o CA 380 V,consumo energetico ≤ 15 VA | ||

| Tensione di lavoro nominale del motore | CA 380 V / 660V,50Hz / 60Hz | ||

| Corrente di lavoro nominale del motore | 1.6(0,40 A-2,00 A) | Misurato utilizzando il modulo di misurazione | |

| 6.3(1,6 A-6,3 A) | |||

| 25(6,3 A-25 A) | |||

| 100(25A-100A) | |||

| 250(63A-250A) | Utilizzando trasformatore di corrente esterno + modulo di misura | ||

| 800(250A-800A) | |||

| Corrente di dispersione | 50mA-1A | Utilizzando il modulo di misurazione + trasformatore di corrente di dispersione | |

| 3A-30A | |||

| Capacità dei contatti di uscita del relè | Carico resistivo | CA 250 V、6UN;DC24V、6UN | |

| Carico induttivo | CA 250 V、2UN;DC24V、2UN | ||

| Ingresso e uscita dell'interruttore principale | 4DI、4FARE,DI Può essere nodo asciutto o bagnato | ||

| Modulo interruttore | 4DI、3FARE,DI Può essere nodo asciutto o bagnato | ||

| Modulo temperatura | Tipo di sensore esterno:PT100、PT1000、Cu50、PTC、NTC

Numero di canali del sensore: 3 Campo di misurazione corrispondente del sensore: PT100/PT1000:-50°C~+500°C Cu50:-50°C~+150°C PTC/NTC:100Ω~30kΩ |

||

| Modulo analogico | Può essere realizzato: 2-modo di misurazione dell'ingresso 4~20mA, 2-uscita di trasmissione 4~20mA

4~ Precisione della misurazione dell'ingresso 20 mA ±0,5% 4~ La capacità di carico massima dell'uscita 20 mA è ≤ 500 Ω |

||

| Comunicazione principale | RS485:Modbus-RTU | ||

| Modulo di comunicazione | RS485:Doppio Modbus-RTU、Profibus | ||

| Ambiente | Temperatura di lavoro | -10ºC~55ºC | |

| Temperatura di conservazione | -25ºC~65ºC | ||

| Umidità relativa | ≤95﹪Nessuna condensa, nessun gas corrosivo | ||

| Altitudine | ≤2000m | ||

| Livello di inquinamento | Livello 3 | ||

| Livello di protezione | Corpo principale IP20, modulo display diviso IP45 (installato sul mobile) | ||

| Categoria di installazione | Livello III | ||

English

English العربية

العربية Български

Български 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά Magyar

Magyar Italiano

Italiano 日本語

日本語 한국어

한국어 Polski

Polski Português

Português Română

Română Русский

Русский Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Tiếng Việt

Tiếng Việt