Temperature control Kit (NTC, PT100, PT1000, DS18B20 energy storage sensor) is an important guarantee for the safe and economic operation of energy storage. In battery energy storage applications, the temperature sensor is mainly responsible for sensing the temperature changes of the battery. When the battery temperature reaches a certain threshold, the BMS will automatically terminate the charging and discharging operations of the battery.

According to incomplete statistics, there were 50 fire and explosion accidents in energy storage power stations in the world in the 10 years from 2011 に 2021. その中で, there were 30 in South Korea, 3 in China, 2 in the United States, 1 in Japan, そして 1 in Belgium. According to China Energy News, の “4.16” Beijing Dahongmen Energy Storage Power Station accident in 2021 caused 3 deaths, 1 injury, and direct losses of 16.6081 million yuan.

Analysis of the causes of some energy storage safety accidents

The main causes of energy storage power station accidents are: defects in the lithium battery itself and the management system, thermal runaway inside the lithium battery, and poor heat dissipation during charging and discharging.

The National Energy Administration issued the “14th Five-Year Plan for Power Safety Production”, focusing on the improvement of electrochemical energy storage safe operation technology. の “New Energy Storage Project Management Specifications (Interim) (Draft for Comments)” emphasizes the principle of safety and puts forward safety management requirements for the entire life cycle. . It is proposed that in principle, no new large-scale power battery cascade utilization energy storage projects will be built to avoid the development of high safety issues.

Distribution of energy storage safety event status

1.1 Temperature control Kit as a thermal management executor to ensure the safety of energy storage systems

Thermal management is an important means to ensure the safe operation of energy storage systems:

Improve the safety of energy storage operation from two angles:

①Improve the safety performance of the battery itself and reduce the probability of puncture, short circuit and other adverse conditions, mainly relying on the technical improvement of battery companies.

②Improve the stability of the battery during operation through thermal management, so that the battery is maintained within the safe operating parameter range during charging, discharging, and static states, and avoids entering a thermal runaway state. Mainly rely on BMS to monitor the status of lithium batteries, and rely on temperature control equipment to control the constant temperature and humidity of lithium batteries.

Schematic diagram of the structure of an electrochemical energy storage system

② BMS monitors the temperature changes of energy storage batteries and is the decision maker of thermal management in energy storage systems.

③ Temperature control is the executor of thermal management of energy storage system, which keeps the temperature and humidity of energy storage battery in a suitable state.

The temperature control sensor system implements the BMS thermal management strategy, collects temperature data and adjusts the temperature and humidity of the energy storage system by controlling heating, cooling and other equipment according to a certain logic, so that the battery is in a safe and efficient operation state.

The optimal temperature range of lithium battery is 10-35℃, and the temperature control technology requirements are prominent;

The operating temperature range of energy storage battery and battery out of control;

Temperature and humidity control affects the comprehensive performance of lithium battery and is related to the economic efficiency of energy storage throughout the life cycle

Improper temperature and humidity control will cause lithium battery capacity failure, shortened life, and performance degradation, thereby reducing the economic efficiency of energy storage throughout the life cycle.

Battery operating temperature difference

The main effects of humidity on lithium battery:

Excessive ambient humidity will aggravate the internal reaction of the battery, causing battery bulging and shell rupture, and finally reducing the thermal stability of the electrolyte. The critical time of thermal runaway under the condition of 100% humidity is 7.2% earlier than that under 50% 湿度. Humidity in a certain range aggravates the process of battery thermal runaway.

Temperature has three main effects on lithium batteries:

1) Capacity and life: If the temperature is too high or too low, the electrode material will be damaged, resulting in the dissolution of metal ions, the faster the capacity of the lithium battery decays, and the shorter the cycle life. If the working environment temperature of the battery increases by 15°, the battery life will be shortened by 50%.

2) Thermal runaway risk: If the heat generated by the charging and discharging of the lithium battery cannot be dissipated in time, it will lead to high temperature inside the lithium battery, which is easy to cause problems such as SEI film decomposition and heat release, electrolyte endothermic evaporation, and diaphragm melting. It will lead to short circuits between the positive and negative electrodes, battery failure, and even safety problems such as combustion and explosion in severe cases. 同時に, thermal runaway of a single battery can easily trigger a chain reaction and cause thermal runaway of the energy storage system.

3) Low temperature characteristics: When the temperature is low, the charge transfer of the lithium battery is poor and the charging performance is reduced. At the least, lithium will be precipitated and accumulated at the negative electrode, reducing the capacity and thermal safety of the battery, and at the worst, the diaphragm will be punctured to cause a short circuit. Low temperature will also seriously shorten the battery life. The cycle life of a lithium battery at -40°C is less than half of that at 25°C.

The greater the discharge rate of lithium batteries and the longer the working time, the more heat they produce;

Battery heat production consists of Joule heat and reaction heat, both of which are affected by ambient temperature, working time, and charge and discharge rate.

左: Battery heat release power, heat release and time relationship curve at 20℃; Right: Battery heat release power, heat release and time relationship curve at 1C

① As the charge and discharge rate increases, the battery heat release rate increases significantly. At 20℃, the heat generation rate at 1C rate increases by 530.5% compared with 0.3C;

② It is related to the working time of the battery. The more heat is generated, the more accumulated heat is likely to be caused;

③ The increase in ambient temperature will increase the difficulty of battery convection heat dissipation.

Mdule actual measurement of 1 cycle battery cell temperature rise change diagram

Energy storage system has a large capacity and high rate as the development trend, and the demand for temperature control is expanding

Energy storage has shifted from backup to main use, and actively participated in frequency modulation and peak regulation. Large capacity and high rate have become a development trend, driving the increase in battery heat generation.

Energy storage changes from backup to main use

Schematic diagram of the technical solution of shared energy storage power station

II. Liquid cooling technology in energy storage temperature control

The penetration rate is expected to continue to increase

Energy storage temperature control technology is mainly air cooling and liquid cooling, and heat pipes and phase change are under research.

現在のところ, air cooling and liquid cooling are the main ones, and heat pipe cooling and phase change cooling are in the research stage.

Effect performance of different temperature control technology paths

Air cooling: A cooling method that uses air as a cooling medium and uses convection heat transfer to reduce the temperature of the battery. しかし, due to the low specific heat capacity and thermal conductivity of air, it is more suitable for relatively small power communication base stations and small energy storage systems.

Liquid cooling: Use liquid convection heat transfer to transfer the heat generated by the battery. Since the specific heat capacity and thermal conductivity of liquid are higher than those of air, it is more suitable for high-power energy storage systems, data centers, 新しいエネルギー車, 等.

Heat pipe cooling: Heat pipe cooling relies on the phase change of the working fluid in the closed shell to achieve heat exchange, which is divided into cold end air cooling and cold end liquid cooling. (Currently in the research stage, this article will not discuss it for the time being)

Phase change cooling: Phase change cooling is a cooling method that uses phase change materials to absorb energy. (Currently in the research stage, this article will not discuss it for the time being.)

Comparison between liquid cooling and other temperature control technologies

Air cooling technology: Forced air cooling technology is mature, and air duct design is the key point.

Liquid cooling technology: Liquid cooling has better heat dissipation performance, and customized flow channel design is the difficulty.

Liquid cooling system composition:

It is mainly composed of a refrigerant circulation system, a coolant circulation system (electronic water pump, water cooling pipe, water tank, battery cold plate group) and a control system. The main component is a battery liquid cooling plate.

There are two commonly used modes:

One is direct contact to immerse the battery module in liquid; the other is indirect contact to set a liquid cooling plate between batteries. Liquid cooling requires the use of auxiliary equipment such as electronic pumps. Compared with air cooling, liquid has a high heat transfer coefficient and can be used for cooling large-capacity batteries. It is not affected by altitude and air pressure and has a wider range of adaptability, but the liquid cooling method has a high cost due to expensive equipment. For battery systems, direct contact immersion liquid cooling has the risk of leakage. 現在のところ, the main solution is indirect contact battery liquid cooling plate liquid cooling.

Schematic diagram of water cooling system structure

Liquid cooling pipeline layout

Liquid cooling has higher specific heat capacity and thermal conductivity

CATL liquid cooling box schematic diagram and performance parameters

Liquid cooling has excellent cooling effect, higher space utilization, lower energy consumption, and wider application range.

① Excellent cooling effect: The thermal conductivity of liquid is 3 times that of air, and it takes away more than 1000 times the heat of the same volume of air. Air cooling can generally control the temperature difference of the battery cell within 5-10℃, while liquid cooling can be controlled within 5℃. A better design can control the temperature difference between the coolant inlet pipe and the return pipe within 2℃.

② Higher space utilization: Liquid cooling does not require reserved heat dissipation channels, which greatly reduces the footprint of the energy storage system;

③ Lower energy consumption: Temperature control accounts for about 35% of energy consumption, which is the equipment with the highest energy consumption except IT equipment. Compared with traditional air cooling technology, the liquid cooling system saves about 30% に 50% of electricity consumption. The overall energy efficiency of the data center room using liquid cooling technology will be improved by 30%.

④ Wider application range: Liquid cooling is more adaptable to harsh environments and can better cooperate with wind and solar power generation, such as high-salt land by the sea, deserts, 等.

⑤ Liquid cooling improves battery life: Under liquid cooling technology, battery life can be increased by 10%.

Effect performance of different temperature control technology paths;

Unique advantages of liquid cooling in the field of energy storage;

Heat pipe, phase change cooling: Both are in the research stage and have not yet been used in battery energy storage systems;

Heat pipe cooling relies on the phase change of the working fluid in the closed shell to achieve heat exchange. Phase change cooling is a cooling method that uses phase change materials to absorb energy.

Phase change cooling counting principle;

Heat pipe cooling principle;

Operation diagram of phase change energy storage natural cooling system

Technical status: air cooling has a high market penetration rate at this stage, and liquid cooling products are being promoted

Benefiting from the fact that energy storage development is still in its early stages, most projects are small energy storage systems with small capacity and power. The air cooling efficiency can meet the demand, and the economic advantage supports its high market penetration rate.

The value of air cooling per GWh is 30 million, which is more economical than liquid cooling system

Air cooling has high reliability compared to liquid cooling: ①The air cooling system has a simple structure and is easier to install and maintain. ②Some liquid cooling systems still have risks such as coolant leakage and multiple fault points, and the air cooling system is relatively more reliable.

The efficiency of air cooling can still be improved, and there is still room for market space. Air cooling can improve the efficiency of cooling and heating by optimizing the air duct design, controlling the direction, flow rate and path of the air flow.

Temperature distribution of natural convection and forced air cooling of battery packs;

Value distribution of liquid cooling system solutions;

Mainstream companies such as CATL, Sungrow Power Supply, and BYD have begun to increase the promotion of liquid cooling products.

Technology trends:

(1) Liquid cooling penetration rate increases, and air cooling still has a place

(2) Energy storage profitability is expected to improve, which is conducive to the increase in liquid cooling penetration rate

Compared with ternary batteries, lithium iron phosphate batteries have low costs and can reduce energy storage costs: the price cost of NCM811 ternary lithium batteries is 1.0-1.2 yuan/Wh, and the energy density is 170-200Wh/kg; the price of lithium iron phosphate batteries is 0.5-0.7 yuan/Wh, and the energy density is 130-150 Wh/kg.

The decline in battery prices will bring about an inflection point in the economic efficiency of energy storage

Energy storage system profitability is expected to improve, and liquid cooling penetration rate may increase: According to industry forecasts, the cost of energy storage systems is expected to drop to 0.84 yuan/Wh by 2025. 現在のところ, energy storage is in the early stage of commercial development, with high cost sensitivity and the reliability of liquid cooling technology needs to be improved, so the penetration rate of air cooling is relatively high; as the profit model of energy storage improves, the cost sensitivity decreases, and liquid cooling technology continues to mature and improve, it is expected to drive the penetration rate of liquid cooling to increase.

Lithium iron phosphate batteries are more suitable for energy storage batteries due to their high cost performance

Battery technology has a wide range of applications in energy storage

(3) The demand for large-scale energy storage such as peak load regulation and frequency regulation is expected to increase, which may promote the development of liquid cooling

(4) Liquid cooling solutions can improve the economic efficiency of energy storage throughout its life cycle

New energy sites usually use the levelized cost of electricity (LCOE) to evaluate the economic efficiency. Considering that energy storage has the characteristics of being both a power source and a load, the levelized cost of electricity is used as the core indicator and safety is introduced to evaluate the economic efficiency of energy storage throughout its life cycle. The practical application of liquid cooling temperature control in the field of energy storage can give full play to its technical advantages and achieve the improvement of the economic efficiency of energy storage throughout its life cycle.

3. Multiple growth tracks jointly promote the continuous growth of the temperature control industry

(私) Temperature control technology has the same origin, and energy storage temperature control companies generally enter from other tracks

Energy storage is still in its early stages, and energy storage temperature control companies have all entered from other tracks, mainly precision temperature control companies, new energy vehicle temperature control companies, and industrial temperature control companies.

Comparison of requirements for other temperature control equipment and energy storage temperature control equipment

The energy storage temperature control market structure is uncertain, and the development prospects are high. According to BNEF’s forecast, the world will invest $262 billion in the next ten years to deploy 345GW/999GWh of energy storage systems, and the downstream demand is strong, driving high growth in temperature control demand. All companies are deploying temperature control energy storage in order to seize new growth poles.

(II) Energy storage temperature control

1. Large-scale energy storage is the key to the development of energy storage and the main track of energy storage temperature control.

Large-scale energy storage is the key to the larger-scale development of energy storage and is expected to maintain a high share. Take the United States and China, the two major markets in the world, as examples: ① The newly added scale of operation in the United States is mainly large-scale energy storage before the table, and the trend of large-scale is obvious. ② The growth point of China’s energy storage lies in the power supply side and the grid side, mainly in peak and frequency regulation.

Large-scale energy storage has the characteristics of large capacity and complex operating environment, and has higher requirements for temperature control systems, which is expected to increase the proportion of liquid cooling.

The scale of the US energy storage market from 2021 に 2026

Shared energy storage projects registered in provinces across the country

2. Industrial and commercial energy storage still needs temperature control, and the demand for temperature control of home storage is relatively low

The development of industrial and commercial energy storage is driven by economics, and a temperature control system needs to be configured to solve the heat dissipation problem:

Factors such as peak electricity price policies, rising electricity costs for high energy consumption, and backup power demand drive the growth of storage demand for industrial and commercial users. Industrial and commercial energy storage needs to rely on temperature control to dissipate heat due to frequent charging and discharging, but the heat generation is small, and the proportion of air cooling is expected to be relatively high.

Home storage is mainly used to save household electricity bills. It has the characteristics of small capacity and low utilization frequency, and the demand for temperature control is relatively small:

The scale of home storage is usually below 30KWh, and it is usually combined with photovoltaic operations, mainly with 1 charging and 1 discharging scenarios, with low heat dissipation requirements and low demand for professional temperature control systems. Tesla Powerwall series is mainly used with electric vehicles and equipped with a complete liquid cooling system. It is similar to the thermal management system of a car and can have heating and cooling functions, but the temperature control system is not universal in other products in the home storage field, and Tesla’s new solution intends to cancel the liquid cooling solution.

Industrial energy storage business model;

Tesla home storage solution;

3. IDC temperature control: “East Data West Computing” adds more power to the industry, and low PUE promotes the penetration rate of liquid cooling

China’s IDC temperature control market size and year-on-year growth rate from 2016 に 2020.

The Internet and cloud computing promote the large-scale development of IDC, そして “East Data West Computing” adds more powerful power.

According to the Ministry of Industry and Information Technology, the scale of my country’s data center market will reach 248.6 billion yuan in 2021. In February 2022, the National Development and Reform Commission, the National Energy Administration and others jointly issued a document agreeing to start the construction of national computing power hub nodes in 8 places including Beijing-Tianjin-Hebei, the Yangtze River Delta, and the Guangdong-Hong Kong-Macao Greater Bay Area, and plan 10 national data center clusters. の “East Data West Computing” project will further accelerate the development of data centers.

The temperature control energy consumption in data centers is high, and temperature control energy saving is the key to reducing PUE.

Air cooling is still the dominant technology, but the penetration rate of liquid cooling is growing steadily. Liquid cooling is expected to be more economical throughout its life cycle, driving its penetration rate to continue to increase:

① Liquid cooling can reduce IDC electricity costs and improve IDC operation economics.

の 10 data center clusters of “East Data West Computing” will drive the rapid development of large and super-large IDCs; but the larger the IDC, the greater its energy consumption and the greater its operating costs. According to Huawei’s survey, for a 10MW IDC, the electricity cost accounts for more than 60% of the overall operating cost of the IDC during its 10-year life cycle. Academician Wu Hequan proposed that replacing air conditioning cooling with liquid cooling can save 30% of electricity compared to traditional methods, effectively reducing operating costs. From the perspective of overall IDC operation, large and super-large IDCs are more suitable for liquid cooling technology.

② The localization of cooling liquid promotes the improvement of the economic efficiency of liquid cooling technology itself.

Alibaba Cloud has begun to build super-large IDCs with immersion liquid cooling technology. The PUE value of IDC can be as low as 1.15, and is currently trying to replace the key link cooling liquid with domestic ones. If the research and development is successful, the cost of immersion liquid cooling data centers will be greatly reduced, the commercial maturity of liquid cooling technology will be improved, and the penetration rate of liquid cooling will be promoted.

Energy consumption distribution of data centers with different PUE;

The cumulative number of 5G base stations built and put into operation in my country (10,000);

4. Temperature control of new energy vehicles: The penetration rate of new energy vehicles continues to increase, and liquid cooling has become the mainstream.

The scale of new energy vehicles is gradually expanding, and the penetration rate is rising.

According to statistics from the China Automobile Association, the annual sales of new energy vehicles in my country exceeded 3.5 百万 2021, の増加 113.9% year-on-year, and the penetration rate increased to 13.4%. According to statistics from Gasgoo, the sales of pure electric passenger vehicles in 2021 reached 2.734 million, an increase of more than 120% year-on-year. The production and sales of new energy vehicles in my country are still showing a high growth trend.

Power batteries are greatly affected by temperature, and battery temperature control drives the value of thermal management of new energy vehicles to increase.

Heat accumulation in the power battery pack can easily cause uneven internal temperature of the battery, affecting its consistency, reducing the efficiency of the charge and discharge cycle, affecting the power and energy of the battery, and in severe cases, it will also lead to thermal runaway, affecting system safety and reliability.

2014-2021 H1 China New Energy Vehicle Sales Statistics and Growth;

2015-2020 China New Energy Vehicle Penetration Analysis (ユニット:%);

Liquid cooling has become the mainstream temperature control technology for new energy vehicles: Tesla, BYD and other representative companies have adopted liquid cooling technology in thermal management technology, and liquid cooling has also become the main cooling method for power batteries.

Car companies have increased their requirements for battery heat dissipation, and the penetration rate of liquid cooling continues to rise. According to statistics, で 2019, のみ 6% of customers required that the power battery pack should not diffuse heat; で 2020, the proportion increased to 14%; で 2021, it increased significantly to 86%, and accordingly, the penetration rate of liquid cooling will continue to rise.

Iteration of domestic PACK integration technology (representative enterprises);

Statistics of CATL customer heat dissipation requirements;

IV. Calculation of power storage temperature control market space

It is estimated that the global power storage temperature control market will reach 9.10 billion yuan in 2025, of which air cooling and liquid cooling account for 46.83% そして 53.17% それぞれ. From 2021 に 2025, the global power storage temperature control market size CAGR will reach 103.65%. Calculation and results of temperature control market space in other tracks: で 2025, the temperature control market of other related tracks such as IDC, 5G base stations and new energy vehicles will reach a total of 244.591 billion yuan; CAGR from 2021 に 2025 will reach 15.19%

Core assumptions for the calculation of the global power storage temperature control market space:

Calculation of the global power storage temperature control market from 2020 に 2025;

Calculation of the temperature control market space of other tracks from 2020 に 2025;

V. Energy storage temperature control and temperature sensor

1. Temperature Application of temperature sensors in energy storage temperature control

“Temperature sensors are used in energy storage, mainly in household and industrial and commercial energy storage, 通信エネルギー貯蔵, and grid-level box energy storage. We have not yet entered this business.” Huagong Gao Li told the temperature sensor researcher, “The demand for this business is small and cannot meet our scale requirements.

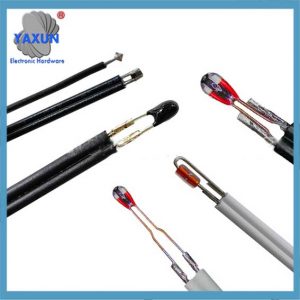

(YAXUN box energy storage CCS-screw fixing solution)

“Our YAXUN temperature sensors are mostly used in household and industrial and commercial energy storage, 通信エネルギー貯蔵, and grid-level box energy storage. “We will launch the energy storage CCS battery module temperature/voltage acquisition solution in 2022, using home/commercial energy storage CCS, communication energy storage CCS, and box-type energy storage CCS to solve the corresponding different energy storage temperature acquisition problems. CCS (Cells Contacting System), あれは, the wiring harness board integration, acquisition integration, assembly or wiring harness isolation board. Energy storage CCS, installed on the battery pack, forming a set of battery modules.

(YAXUN home/commercial energy storage CCS-FPC solution)

“Our energy storage CCS, through copper and aluminum bars, realizes the series and parallel connection of battery cells, outputs current; collects battery cell voltage; collects battery cell temperature. We have screw fixing solutions, laser welding solutions, ultrasonic welding solutions, and FPC solutions. ”

(YAXUN Communication Energy Storage CCS-Laser Welding Solution)

2. Application of temperature sensors in energy storage sales channels

The sales team of the temperature sensor company should judge whether its product advantages are suitable for grid-level energy storage customers. It is also necessary to judge whether there is a team that is deeply engaged in the power grid and grid-level energy storage industry. もしそうなら, then set up a “grid industry temperature sensor sales team”. Expand product manufacturers involved in power generation, transmission, and distribution. Many products can use temperature sensors. It is also necessary to deeply cultivate the grid-level energy storage industry. 加えて, energy storage temperature control manufacturers are also important target customers for temperature sensors!

Multiple forces are competing for the energy storage temperature control market. The current participants in the energy storage temperature control market are roughly divided into three categories: data center temperature control manufacturers, industrial temperature control manufacturers, and automotive thermal management manufacturers.

ついに, it is necessary to remind that companies that provide temperature control equipment and solutions for grid-level energy storage are also customers of temperature sensors!

English

English العربية

العربية Български

Български 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά Magyar

Magyar Italiano

Italiano 日本語

日本語 한국어

한국어 Polski

Polski Português

Português Română

Română Русский

Русский Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Tiếng Việt

Tiếng Việt