제품 카테고리

- 온도 퓨즈 32

- 표면 마운트 퓨즈 12

- 서미스터 36

- PCB 마운트 퓨즈 홀더 27

- 배선 하니스 6

- 블레이드 퓨즈 홀더 17

- 온도 조절기 50

- 전기 퓨즈 24

- 자동차 온도 센서 7

- 열 회로 차단기 22

- 퓨즈 박스 홀더 36

- 온도 센서 75

- 열 스위치 68

- 자동차 퓨즈 20

- 퓨즈를 볼트로 낮추십시오 8

제품 태그

맞춤형 바이메탈 디스크 스냅 온도 조절기

KSD301/KSD302 (아니오/NC) 일련의 제품은 가장 널리 사용되는 바이메탈 디스크 온도 조절 장치입니다.. 야쉰에 위치, 고정밀 접시형 바이메탈 스탬핑을 제공합니다., 온도 분류, 집회, 제품 테스트 원스톱 서비스. 시장 요구에 맞는 제품 개발, 다양한 제품 사이즈가 있어요, 다양한 온도 조절 방법.

KSD301/KSD302 (아니오/NC) 일련의 제품은 가장 널리 사용되는 바이메탈 디스크 온도 조절 장치입니다.. 야쉰에 위치, 고정밀 접시형 바이메탈 스탬핑을 제공합니다., 온도 분류, 집회, 제품 테스트 원스톱 서비스. 시장 요구에 맞는 제품 개발, 다양한 제품 사이즈가 있어요, 다양한 온도 조절 방법. 신제품을 개발하는 경우, 제품 열 보호기를 알아야합니다, 전문 팀에 문의하십시오, 만족스러운 제안과 샘플을 얻을 수 있습니다.

이중 메탈 디스크 온도 조절 장치는 무엇입니까??

KSD301 시리즈 온도 감지 요소는 바이 메탈입니다, 가장 일반적으로 사용되는 전기 과열 보호입니다. 전기 작업시, 바이 메탈은 자유 상태에 있습니다, 연락처는 닫힙니다 / 연결이 끊어진 상태, 전기 기기의 온도가 정상적으로 상승하지 않을 때, 이중 메탈 디스크 온도 조절기의 보호 조치 온도에 도달하면, 열 영향이 바이 메탈릭에 따라 다릅니다, 내부 스트레스와 빠른 행동을 생성합니다, 열려 있는 / 밀접 접촉, 끄다 / 턴온 회로, 온도에서 보호 역할을합니다. 전기 냉각이 재설정 온도로, 연락처가 자동으로 닫혔습니다 / 열려 있는, 힘을 켜십시오, 정상적인 작업 조건으로 돌아갑니다. KSD301 제품 시리즈 제품은 일반적으로 수만 번 반복 될 수 있습니다..

이중 메탈 디스크 온도 조절기 특성

안정적인 성능, 높은 정밀도;

작은 크기, 가벼운 무게;

아크를 당기지 마십시오, 정밀한 구조;

재사용 할 수 있습니다, 장수;

널리 사용됩니다, 다각화의 설치;

고전력, 대형 현재 전기 기기에 적용 할 수 있습니다;

무선 건조 걱정이 작습니다.

제품 모델 표현 방법

k s d 301 / □ □ □ / □***

K 클래스 코드: K- 테어 스테

연락처 조치 모드 s: 에스- 즉각적인 행동, 중- 느리게 행동합니다

D 온도 설정 모드: d-fixed, T- 조정 가능

301 디자인 코드: 301

고정 양식: 1 – 고정 알루미늄 커버, 2 – 활성 링 프리 고정, 3 – 고정되지 않았습니다

말기 자세: 1 – 수준; 2. 수직의; 3-만곡부 45 °; 4. 수평의 / 수직의; 5-수준 / 만곡부 45 °; 6. 수직의 / 구부러진 발 45 °; 7 – 핀 없음; 8 – 다른 각도

터미널 유형: 1-250 시리즈; 2-187 시리즈; 3-비표준 터미널

작동 온도 범위 공칭 값: 3 숫자 + 온 오프 모드 + 1-비트 범위 절대 값.

제어 방법

수년간의 기술 개발 후 KSD 일련의 온도 제어, 다양한 온도 제어 방법의 생성물에 적응하기 위해, Ya xun에서, 다른 고객의 요구 사항을 충족합니다, 다양한 온도 제어 제품의 개발:

1. 자동 재설정: 온도에 따라 변화하거나 감소합니다, 내부 접점은 자동으로 연결이 끊어 지거나 자동으로 닫힙니다.

2. 수동 재설정 (건조 방지 유형): 주로 온수기에 사용됩니다, 온도가 올라가면, 연락처가 자동으로 연결됩니다; 컨트롤러 온도 냉각시, 접점을 다시 재설정하려면 버튼을 수동으로 눌러야합니다..

3. 일반적으로 닫혔습니다(체크 안함): 전기 기기가 제대로 작동합니다, 연락처가 닫힙니다, 온도 조절기는 전력 상태에 있습니다, 온도가 작동 온도에 도달 할 때, 바이메탈 시트 열은 내부 응력을 생성했습니다, 그리고 빠른 행동, 연락처를 엽니 다, 차단 / 회로에, 온도 제어에서 중요한 역할을합니다.

4. 상시 개방형(아니요): 전기 작업, 접촉은 열린 상태에 있습니다, 온도 조절기는 전력 상태에 있습니다. 온도가 작동 온도에 도달하면, 바이메탈 시트 열은 내부 응력을 생성했습니다, 그리고 빠른 행동, 닫힌 연락처, 냉각 전원 공급 장치에 연결됩니다, 열 발생 요소의 온도 감소, 보호 역할을 수행합니다.

5. 기존의 전기 매개 변수 유형: 1) AC250V 50 ~ 60Hz 5A / 10ㅏ / 15ㅏ (저항 부하)

2) UL AC125V 50Hz 15A (저항 부하)

6. 고전력 유형 (KSD302): AC250V 또는 400V; 50 / 60헤르츠

1) 16ㅏ; 20ㅏ; 25ㅏ; 30ㅏ; 35ㅏ

2) 50ㅏ; 55ㅏ; 60ㅏ;

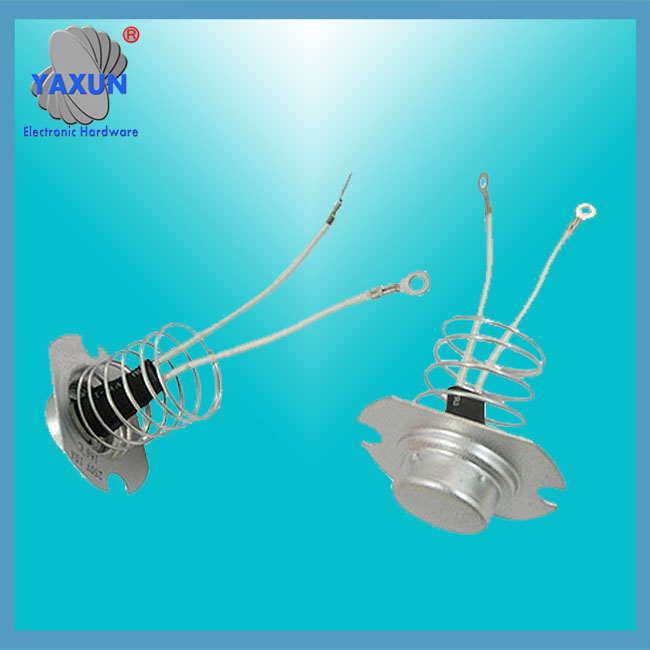

7. 제상 유형: 주로 냉장고 제동기 제어에 사용됩니다. 압축기에서 특정 시간으로 실행됩니다, 온도 직후 -14 ° C 증발기의 해동 온도 조절기에 의해 느껴지는 것, 전류를 켜십시오, 현재 제상 타이머 작동, 해동 히터가 작동하기 시작했습니다, 제상 온도 조절기가 느껴질 때 +5 ℃, 제상 온도 조절 장치 접점이 열립니다, 제상 온도 조절 장치 (튜브) 작업을 중단합니다.

제품 구조

KSD301 온도 제어 스위치 시리즈, 온도 조절 장치 액세서리의 기본 구성 요소:

껍데기 (베이클라이트, 세라믹), 알루미늄 커버 (스테인레스 스틸 커버, 구리 스터드), 터미널, 콘택트 렌즈, 리벳, 정적 접촉, 이사 리드, 온도 시트 (바이메탈 시트) 등, 정밀 온도 조절기 제조, 12 개 이상의 프로세스가 필요합니다, 자동화 된 기계 장비로 조립.

1, KSD301 쉘 (베이클라이트와 도자기)

2.KSD301, KSD302 알루미늄 커버 (열 및 보호 효과)

3.KSD301 터미널 6.3mm 4.8mm (연결 전도 효과)

스크류가있는 디스크 스냅 온도 조절기 | 터미널 크기 AXB | 4.8×0.5 | 4.8×0.8 | 6.3×0.8 |

| 축력 n | 50 | 60 | 70 |

4, 연락처 (은과 구리의 접촉, 실버 도트 제품 비싸다)

5, 리벳 (연결 및 고정)

6, 고정 접촉 조각 (구리)

7, 움직일 수있는 봄 (구리)

8, 온도 시트 (바이메탈)

제품 기술 매개 변수 및 용어

KSD301 온도 조절기 정밀 온도 컨트롤러. 디자인의 제품, 생산, 테스트에, 표준 기술 요구 사항입니다. 그가 Xun이라면, 독립 실험실, 시장을 안내하기 위해 온도 조절기 산업 표준을 설정함으로써, 전문 기술 팀에 연락 할 때, 먼저 제품 설계 및 설치의 기술 매개 변수를 제공해야합니다.. 최상의 결과를 얻기 위해, 우리의 엔지니어는 귀하의 제품 응용 프로그램을 신중하게 연구해야합니다, 적절한 설치 및 온도 제어를 최적화하기 위해. 온도 조절기를 피하기 위해 배선 첨가를 포함 할 수 있으며 가열체는 닿지 않습니다., 제품의 온도 제어 정확도에 영향을 미칩니다. 회사의 온도 조절기 생산 표준을 매개 변수로 제발하십시오:

GB / T14536.1-12008 가정 및 유사한 목적을위한 자동 컨트롤러 – 부분 1: 일반적인 요구 사항

GB14536.10-2008 가구 및 이와 유사한 용도의 자동 제어를위한 온도 민감한 컨트롤러에 대한 특정 요구 사항

JB / T3751-1997 가정 및 유사한 바이메탈 온도 제어기

IDT IEC730-1: 2008 UL873

1, 전기적 매개변수: 1) CQC, VDE, UL, 컬, AC250V 50 ~ 60Hz 5A / 10ㅏ / 15ㅏ (저항 부하)

2) UL AC 125V 50Hz 15A (저항 부하)

2, 작동 온도 범위: 0 ~ 240 ℃ (선택 과목), 온도 정확도: ± 2 ± 3 ± 5 ± 10 ℃

3, 응답 및 동작 온도 차이: 8 ~ 100 ℃ (선택 과목)

4, 배선 방법: 플러그 터미널 250 # (만곡부 0 ~ 90 ° 선택사항); 플러그 터미널 187 # (만곡부 0 ~ 90 ° 선택사항, 두께 0.5, 0.8MM 선택 사항)

5, 서비스 수명: ≥ 100000 타임스

6, 전기 강도: AC 50Hz 1800V 1분간 지속, 깜박임이 없습니다, 고장 없음

7, 접촉 저항: ≤ 50mΩ

8, 단열성 저항: ≥ 100m

9, 연락 양식: 일반적으로 닫혔습니다: 온도 상승, 연락처 오픈, 온도 강하, 연락처가 연결됨;

일반적으로 열려 있습니다: 온도 상승, 연락처가 연결됨, 온도 강하, 연락처 오픈

10, 쉘 보호 클래스: IP00

11, 접지: 온도 조절기 금속 쉘 및 장치에 연결된 금속 부품을 통해.

12, 설치: 어머니 또는 용접 강화.

13, 온도 범위: -25 ℃ ℃ +240 ℃.

14, 온도 설정 온도를 설정하십시오

온도 조절기의 온도 대상 값은 정상 작동 조건에서 온도가 목표 값으로 상승하거나 떨어지면 자동으로 분리되거나 켜집니다..

15, 온도 온도 차이

온도가 온도 조절기에서 설정 될 때 자동 온도와 끄기 회로의 온도 차이.

16, 작동 온도

온도가 온도 조절기의 특정 온도 값으로 설정된 경우, 온도 상승 접촉이 열려 있거나 온도 값을 제어하기 위해 온도 드롭 접촉이 켜지거나 꺼집니다..

설치 예방 조치

온도 조절 장치는 일종의 과열 방지 구성 요소입니다, 전기 안전의 보호입니다, 우리는 좋은 온도 조절 장치를 선택합니다, 동시에 제품 설치 표준에주의를 기울이십시오., 제품 성능 및 특성의 더 나은 적용에 관해, 제품의 안전한 사용을 보장합니다.

1, 알루미늄 커버의 이중 디스크 온도 조절기 설치는 붕괴의 최상위가 될 수 없습니다., 느슨하거나 변형, 알루미늄 덮개를 피하려면 가열 요소와 잘 접촉 할 수 없습니다., 온도 효과에 영향을 미칩니다;

2, 액체가 KSD301 온도 조절기 내부에서 침투 할 수 없습니다.,

3, 바이 메탈 디스크 온도 조절 장치 쉘 균열은 제품을 교체해야합니다,

4, 터미널에는 여러 가지 모양이 있습니다, 고객의 요구 사항이 적용됩니다, 설치가 고객 요구 사항을 충족하지 않는 경우, 또한 터미널 설치를 임의로 변경할 수는 없습니다.

5, 이중 메탈 디스크 온도 조절기 저장 창고 요구 사항: 상대 습도보다 적습니다 90%, 아래 주변 온도 40 ℃, 환기, 마른, 비발적 가스.

6, 이중 메탈 디스크 온도 조절기 설치, 알루미늄 덮개는 가열체에 가깝습니다., 온도의 영향을 보장하기 위해, 가열 요소의 표면은 열 실리카 겔로 코팅되어야합니다., 가열체 표면에 고정 된 온도 조절기.

7, 바이 메탈 디스크 온도 조절기에는 현재 옵션이 다릅니다 (5ㅏ, 10ㅏ, 15ㅏ, 20ㅏ …. 50ㅏ), 전류의 제품 사양이 5A 인 경우, 현재 전기 가전 제품을 5A 이하로 사용할 수 없습니다..

다음 프로젝트를 시작하십시오

다른 전기 프로젝트에 적용되는 이중 메탈 디스크 온도 조절기의 경우, 우리의 전문 팀은 전기 기기 보호를 분석하고 비교할 것입니다., 가장 적합한 열 보호기 중 하나를 선택하십시오.. 제품 간의 가격 차이뿐만 아니라, 또한 제품의 잠재적 성능 장점도 있습니다, 프로젝트 처리 시간. 무료 따옴표 및 프로젝트 평가는 오늘 저희에게 연락하십시오.

응용

널리 사용됩니다: 식수대, 온수기, 샌드위치 토스터, 식기세척기, 건조기, 소독 캐비닛, 전자레인지, 전기 커피 포트, 전기 밥솥, 냉장고, 에어컨, 플라스틱 기계, 사무용품, 카시트 히터 전기 기기.

바이메탈 디스크 스냅 온도 조절 장치

자동차 용 디스크 온도 조절기

열 스위치 제어 방법

고전류 디스크 온도 조절 장치

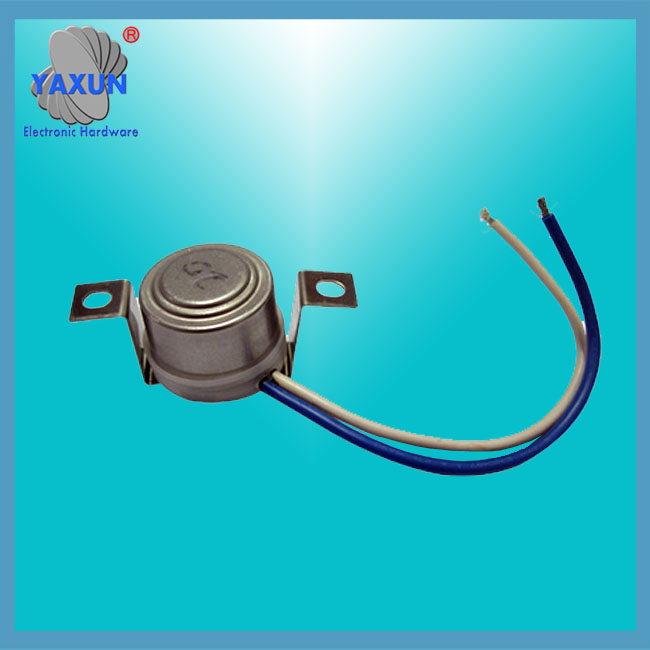

케이블이있는 이중 모온 조절기

수동 재설정 이중 열차 차단 스위치

문의하기

이메일을 기다리는 중, 이내에 답변해 드리겠습니다. 12 필요한 귀중한 정보를 몇 시간 동안.

English

English Afrikaans

Afrikaans العربية

العربية বাংলা

বাংলা bosanski jezik

bosanski jezik Български

Български Català

Català 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Hrvatski

Hrvatski Čeština

Čeština Nederlands

Nederlands Eesti keel

Eesti keel Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά हिन्दी; हिंदी

हिन्दी; हिंदी Magyar

Magyar Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Latviešu valoda

Latviešu valoda Lietuvių kalba

Lietuvių kalba македонски јазик

македонски јазик Bahasa Melayu

Bahasa Melayu Norsk

Norsk پارسی

پارسی Polski

Polski Português

Português Română

Română Русский

Русский Cрпски језик

Cрпски језик Slovenčina

Slovenčina Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Українська

Українська اردو

اردو Tiếng Việt

Tiếng Việt