Productcategorieën

- Thermische stroomonderbreker 20

- Zekeringkast-houder 36

- Temperatuursensor 67

- Thermische schakelaar 64

- Auto zekering 19

- Zekeringen vastschroeven 7

- thermische zekering 32

- opbouwzekeringen 12

- thermistor 22

- PCB-gemonteerde zekeringhouder 27

- Kabelboom 6

- Blade-zekeringhouders 17

- thermostaat 46

- Elektrische zekering 14

Producttags

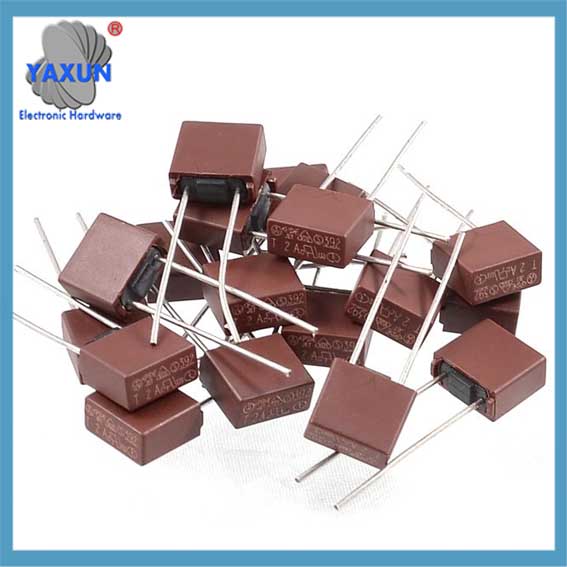

Zwart / Rood Vierkant Type Tijdvertraging Micro DIP Gemonteerde Miniatuur Zekeringen

Black Red Square Type Slow Blow Radial Lead DIP Micro Fuses

Description Of Square Type Slow Blow Radial Lead Micro Fuses:

Nominale spanning: 250V

Materiaal: Base and Cap: Black thermoplastic, Pin: Tin-lead Plated alloy

Certificaat : CUL、UL

AC Adapter Current:2.5 Versterkers

Merk:Baomain

Spanning:250 Volts

Materiaal:lead

Specificatie:Met UL

Over dit artikel

Productnaam : Micro-zekering; Leadtype : Radiaal

Nominaal vermogen : 250V, 2.5A (T2.5A); Breekcapaciteit : 50A (250V AC); Time-lag : 2.5A

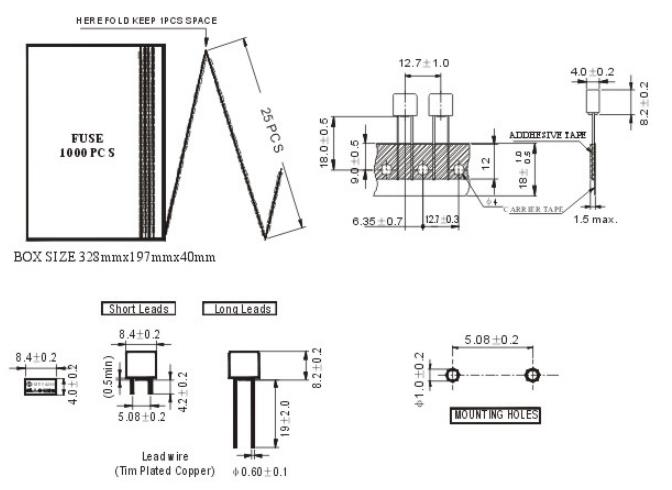

Lichaamsgrootte : 8 X 7 x 4mm/ 0.31″ x 0.27″ x 0.16″(L*W*T)

Leads Size : 0.5 x 19mm/ 0.2″ x 0.75″ (D*L)

Weight : 10g; Package Content : 20 x Micro Fuse

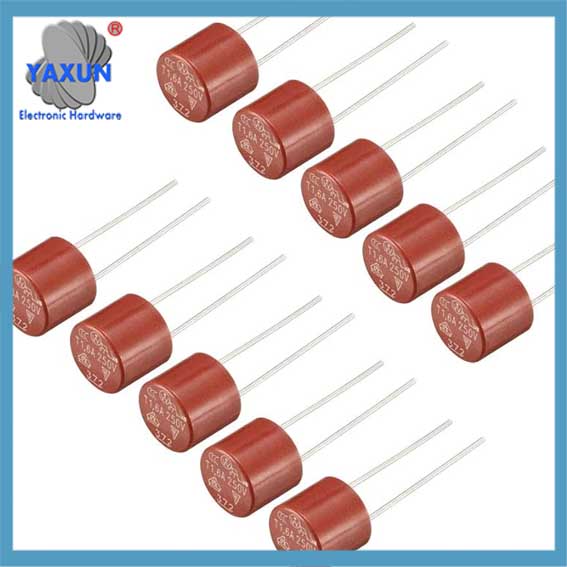

DIP Mounted Miniature Cylinder Slow Blow Micro Fuse 250V Red |

uxcell Vierkant Type Slow Blow Radiale Lood Micro Zekering voor Elektronische Onderdelen PCB LCD Reparatie Vervanging |

Zwart / Rood Vierkant Type Tijdvertraging Micro DIP-zekering |

① DIP Mounted Miniature Square can be divided into square type miniature fuse and cylindrical type miniature fuse according to shape, with sizes of 8*8*4mm, 8.5*8mm, 8.5*8*4mm respectively; current range from 50mA-6.3A 125V/250V;;

Models include: AR5\AP5\AMF\AF\372\382\370\392\2000\2010\MEF\MET\MSF\MST, enz.

② DIP Mounted Miniature Square can be divided into fast blow and slow blow according to fuse performance.

③ According to standards, it can be divided into American and European standards, and the certifications obtained are: UL\VDE\SEMKO\CUL\CCC\EK\PSE, enz.

The influence of working environment temperature on fuse life:

Excessive ambient temperature will damage the life of the fuse. For time-delay (slow-blow) fuses such as tin ball type, tin begins to diffuse into the metal wire when the temperature is about 160℃ (150~170℃). The temperature at which the fusible element (metal wire) of the fast-blow fuse begins to oxidize more violently is about 200℃ (175~225℃). With the oxidation of the fuse from the outside to the inside, multiple diffusions, thermal stress fatigue, enz., the life of the fuse will gradually shorten. Daarom, it is recommended that the time-delay fuse should not work for a long time above 150℃, and the fast-blow fuse should not work for a long time above 175~225℃.

The influence of pulse current on the life of the fuse:

Continuous pulse impact will produce thermal cycles, which will cause diffusion, oxidation, thermal stress, enz. of the fuse, and even accelerate it. The fuse will gradually age with the increase of pulse energy and number of times. The impact resistance life of the fuse depends on the percentage of the pulse I2t to the fuse’s own I2t. Normaal gesproken, it should be less than 20[%], so that the fuse can withstand more than 100,000 impacts.

Such as the pipe clamp in contact with the fuse, and the length and cross-sectional area of the connecting wire. The contact resistance between the fuse and the pipe clamp is large, which is detrimental to the life. The UL standard stipulates that the contact resistance between the fuse and the pipe clamp is less than 3mΩ during the test. When the contact resistance is large, the pipe clamp does not dissipate heat but generates heat and transmits it to the fuse.

Size Of MTS 8X4mm Time Lag Radial Lead Micro Fuses

Neem contact met ons op

Wachten op uw e-mail, wij zullen u binnen antwoorden 12 uur met waardevolle informatie die u nodig had.

English

English العربية

العربية Български

Български 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά Magyar

Magyar Italiano

Italiano 日本語

日本語 한국어

한국어 Polski

Polski Português

Português Română

Română Русский

Русский Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Tiếng Việt

Tiếng Việt