Productcategorieën

- Thermische stroomonderbreker 20

- Zekeringkast-houder 36

- Temperatuursensor 67

- Thermische schakelaar 64

- Auto zekering 19

- Zekeringen vastschroeven 7

- thermische zekering 32

- opbouwzekeringen 12

- thermistor 22

- PCB-gemonteerde zekeringhouder 27

- Kabelboom 6

- Blade-zekeringhouders 17

- thermostaat 46

- Elektrische zekering 14

Producttags

LEEUW, KLEURSTOF, Panasonic, SWC Limiter thermische zekering

Het smeltmateriaal dat wordt gebruikt in LEAO, KLEURSTOF, Panasonic, SWC thermische zekeringen spelen een cruciale rol in de prestaties van thermische zekeringen en vormen een van de kerncomponenten van het hele apparaat. Volgens de kenmerken van het smeltmateriaal, we kunnen ze in twee categorieën verdelen: laag smeltpunt en hoog smeltpunt.

The fuse materials used in LEAO, KLEURSTOF, Panasonic, SWC thermal fuses include copper, aluminum, iron and other elements, and copper is one of the most widely used materials. Copper fuses can be quickly melted when the current is overloaded due to their excellent conductivity, solid texture, good oxidation resistance and high temperature resistance. Thus, electrical equipment is effectively protected and electrical safety is ensured.

Het smeltmateriaal dat wordt gebruikt in LEAO, KLEURSTOF, Panasonic, SWC thermische zekeringen spelen een cruciale rol in de prestaties van thermische zekeringen en vormen een van de kerncomponenten van het hele apparaat. Volgens de kenmerken van het smeltmateriaal, we kunnen ze in twee categorieën verdelen: laag smeltpunt en hoog smeltpunt. Low melting point materials represented by tin and lead are usually made into the thickest cross-sectional shape because of their easy melting and relatively large resistivity characteristics, so the amount of metal vapor generated during the melting process is relatively large. These specific properties make this type of material more suitable for thermal fuse structures with lower breaking capacity. Anderzijds, high melting point materials, such as copper and silver, are more suitable for making smaller cross-sectional sizes because they are not easy to melt and have relatively low resistivity. In aanvulling, relatively less metal vapor is generated during the melting process, so this type of material is more suitable for use in thermal fuse designs that require high breaking capacity.

Bedrijfstemperatuurbereik:

SF type is 73 ℃ ~ 240 ℃, SM type is 76 ℃ ~ 187 ℃. There are various products with a rated current of 0.5A to 15A. Safety certifications include: UL, CSA, VDE, BEBA, PSE, JET, CQC … certificates. Comply with EU ROHS environmental protection directive requirements. NEC temperature fuse has the function of detecting abnormal temperature and cutting off the circuit. It can detect abnormal temperature rises of household or industrial electrical products and quickly and timely cut off the circuit, which can prevent the fire from being unburned.

NEC thermal fuse is a component that provides very reliable protection in over-temperature conditions. It has small volume, grote overstroom, non-reset, stabiele prestaties, convenient installation, and has a range of humidity settings and carrying capacity to choose from to meet customer application requirements.

Producten worden veel gebruikt in:

Various motors, kopieer, Faxmachines, Verborg ballasten, fluorescerende verlichtingsschoenen, transformatoren, opladers, batterijspakketten, Verwarmingsapparatuur, elektrische strijkijzers, hot air blowers, elektrische kachels, rijstkokers, waterkokers, coffee makers, Ventilation fans, Elektrische fans, elektrische naaimachines, waterverwarmers, Power Converters, power plug sockets, koelkasten, airconditioners, automotive air conditioners, meters, apparatuur, enz. are over-temperature protected.

LE series (15A)

Productfuncties

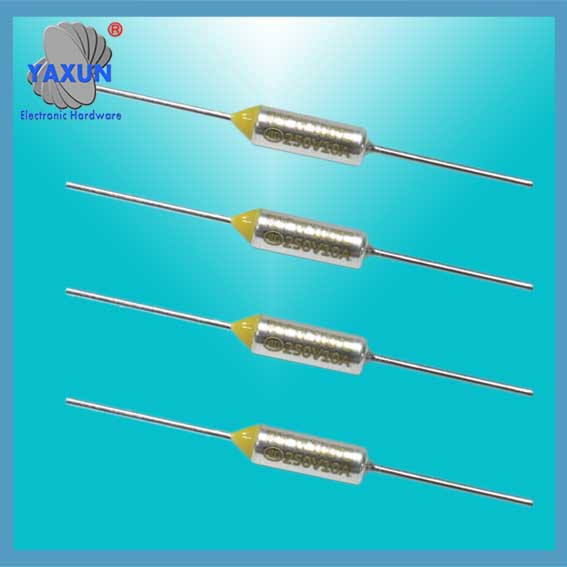

Using temperature fuse metal casing and sense temperature organic particles.

Belonging unrecoverable type thermal fuses. Temperature fuse melting off, even if the surrounding temperature falls, it will not be turned on.

No lead (Pb) and cadmium (Cd), and comply with RoHS.

REACH does not contain the specified 46 categories SVHC (SVHC).

Ceramic thermal fuse

NEC SF thermische zekering

DYE thermal fuse

LEAO thermal fuse

Product Size

Cable length | Dimensies (mm) | ||||

A | B | C | D | E | |

Standard LE | 4.0±0,1 | 20±3 | 10.1±3 | 35±3 | 1.0±0,1 |

Long LE(L) | 4.0±0,1 | 38±3 | 10.1±3 | 35±3 | 1.0±0,1 |

Model | Rated temperature | Bedrijfstemperatuur | Nominale stroom | Nominale spanning | maintaining the temperature | Maximum temperature limit |

LE070 | 73 | 71±2 | 15.0 | AC250 | 50 | 150 |

LE073 | 77 | 74±2 | 15.0 | AC250 | 50 | 150 |

LE080 | 84 | 80±2 | 15.0 | AC250 | 50 | 150 |

LE090 | 94 | 91+3/-2 | 15.0 | AC250 | 65 | 150 |

LE095 | 99 | 95±2 | 15.0 | AC250 | 71 | 150 |

LE108 | 113 | 109±2 | 15.0 | AC250 | 85 | 150 |

LE117 | 121 | 117±3 | 15.0 | AC250 | 95 | 160 |

LE124 | 128 | 124±3 | 15.0 | AC250 | 102 | 160 |

LE128 | 133 | 129+3/-2 | 15.0 | AC250 | 105 | 160 |

LE138 | 142 | 138±3 | 15.0 | AC250 | 110 | 160 |

LE152 | 157 | 152±2 | 15.0 | AC250 | 130 | 175 |

LE169 | 172 | 167±2 | 15.0 | AC250 | 145 | 190 |

LE189 | 192 | 189±3 | 15.0 | AC250 | 165 | 300 |

LE213 | 216 | 213±2 | 15.0 | AC250 | 190 | 300 |

Neem contact met ons op

Wachten op uw e-mail, wij zullen u binnen antwoorden 12 uur met waardevolle informatie die u nodig had.

English

English العربية

العربية Български

Български 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά Magyar

Magyar Italiano

Italiano 日本語

日本語 한국어

한국어 Polski

Polski Português

Português Română

Română Русский

Русский Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Tiếng Việt

Tiếng Việt