Kategorie produktów

- Wyłącznik termiczny 20

- Uchwyt skrzynki bezpieczników 36

- Czujnik temperatury 67

- Wyłącznik termiczny 64

- Bezpiecznik samochodowy 19

- Przykręcić bezpieczniki 7

- bezpiecznik termiczny 32

- bezpieczniki do montażu powierzchniowego 12

- termistor 22

- Uchwyt bezpiecznika do montażu na płytce drukowanej 27

- Wiązka przewodów 6

- Uchwyty bezpieczników ostrza 17

- termostat 46

- Bezpiecznik elektryczny 14

Tagi produktów

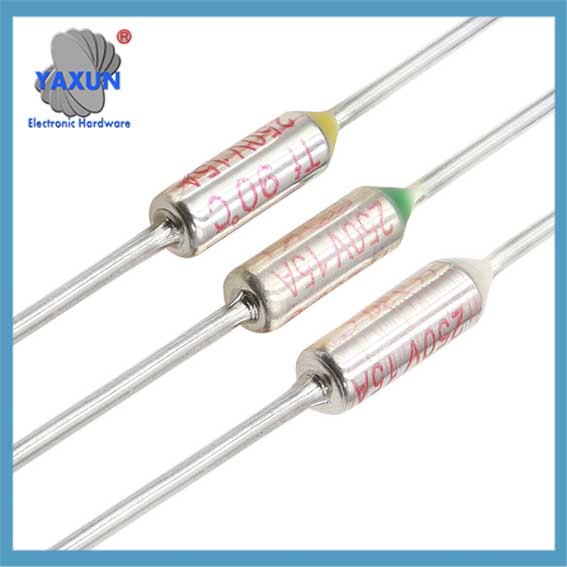

Metalowe bezpiecznik termiczny dla ograniczania ochrony temperatury

Metalowe łącze bezpieczników termicznych (odcięcie termiczne ) składa się z przesuwnego kontaktu, Wiosna, i elektrycznie niekondukcyjny osad termiczny. Przed aktywowaniem granicy bezpiecznika termicznego, Prąd przepływa z lewej strony do przesuwnego styku i przez metalową obudowę do prawego ołowiu. METAL SHERL FUSE FUUSE BELOFF 250VAC 10A TEMPERATURY Połączenie TF 72-250 ℃ (192℃).

Metalowe łącze bezpieczników termicznych (odcięcie termiczne ) składa się z przesuwnego kontaktu, Wiosna, i elektrycznie niekondukcyjny osad termiczny. Przed aktywowaniem granicy bezpiecznika termicznego, Prąd przepływa z lewej strony do przesuwnego styku i przez metalową obudowę do prawego ołowiu. When the external temperature reaches a predetermined temperature, the organic matter meltsand the compression spring becomes loose. That is, the spring expands and the sliding contact is separated from the left lead. The circuit is opened and the current between the sliding contact and the left lead is cut off.

The metal shell temperature fuse link includes a metal pin, a sealing resin, a shell, a thermal fuse, and two fusible alloys. The metal pin and the two ends of the two fusible alloys are welded and connected. The fusible alloy and part of the metal pin are encapsulated in the insulating space of the shell by the sealing resin, and the thermal fuse is filled in the internal confined space encapsulated by the shell and the sealing resin. The two fusible alloys are welded and connected with the metal pin in an “X” shape, and there is a triangle protruding inward at the bottom of the shell. During the operation of the utility model, the intersection of the two fusible alloys is weak, and the disconnection point starts from the intersection. The metal pin has a relatively large adsorption on the fusible alloy, which is conducive to the contraction of the fusible alloy to the pin, avoiding the situation where the fusible alloy is reconnected. The structure of the shell can reduce the generation of arcs. Avoid sparks and burning safety hazards, improve safety of use, and after disconnection, the shell can also effectively prevent the melted fusible alloy from connecting again, permanently disconnecting the circuit.

1. A novel thermal fuse, comprising a metal pin (1), a sealing resin

(2), a shell

(3), a flux

(4), and two fusible alloys

(5), wherein the metal pin and the two fusible alloys are welded at both ends, the fusible alloys and part of the metal pin are encapsulated in the insulating space of the shell by the sealing resin, and the flux is filled in the internal sealed space encapsulated by the shell and the sealing resin. The invention is characterized in that the two fusible alloys are welded and connected to the metal pin in an “X” shape, and the bottom of the shell has a triangle shape protruding inward.

Our Metal thermal fuses are perfect for when you need an accurate and reliable solution for upper-limit temperature protection.

With our reliable protective thermal fuses, the active trigger mechanism is an exclusively formulated, electrically nonconductive pellet. When a predetermined temperature is reached that pellet melts, allowing the compression spring to relax. The trip spring then slides the contact away from the lead and the circuit is opened.

Widely used in:Transformers, Electric motors, Electric fans, Hair dryers, Żelazka elektryczne, Rice cookers, Copiers, Piece elektryczne, Chargers, power taps, Water dispensers, Coffee makers etc.

Skontaktuj się z nami

Czekam na Twój e-mail, odpowiemy Ci w ciągu 12 godziny z cennymi informacjami, których potrzebujesz.

English

English العربية

العربية Български

Български 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά Magyar

Magyar Italiano

Italiano 日本語

日本語 한국어

한국어 Polski

Polski Português

Português Română

Română Русский

Русский Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Tiếng Việt

Tiếng Việt