Product Categories

Product Tags

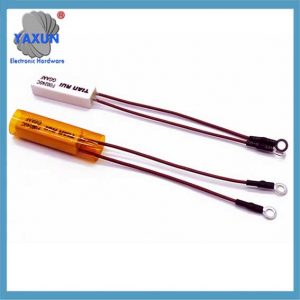

Arlin F00240C 10A 240C Thermal Fuse For GHD Straightener

Thermal Fuse is a very common electronic component used to protect electromechanical equipment from overheating. It is also called over-temperature protector, overheat protection, and temperature protection. The thermal fuse is placed close to the heating part of the electromechanical equipment and connected in series to the equipment power circuit or control circuit. When the temperature of the equipment rises to the rated value of the thermal fuse for some reason, the thermal fuse automatically melts and cuts off the equipment power supply circuit to prevent the equipment from being damaged due to overheating and protect the electromechanical equipment.

Thermal fuse for hair dryer, electric iron, rice cooker, electric stove, transformer, motor |

Thermal fuse for hair straightener overheat protection |

Arlin F00240C 10A 240C Thermal Fuse For GHD Straightener |

As the name suggests, the thermal fuse causes the internal temperature-sensitive material of the thermal fuse close to the equipment to deform when the temperature of the electromechanical or electrical equipment rises to the operating temperature (this value is specified by the thermal fuse manufacturer when manufacturing), thereby disconnecting the power supply circuit.

1. Marking: The manufacturer’s trademark, rated voltage and rated current should be clearly marked on the 240C Thermal Fuse shell.

2. Temperature characteristics: During the test, an indicator with a current of less than 10mA is used to display the circuit on and off.

3. Rated operating temperature (TF): Place the sample in a thermostat, keep it at TF-20℃ for 2 hours, and then heat it up at a rate of 0.5~1K to the melting temperature. The melting temperature should be within the deviation range.

4. Keeping temperature (TC): Place the sample in a thermostat, apply a voltage not exceeding the rated voltage, and a load current of 10A. Place it at TC-6℃ for 168 hours. After the test, the sample should not be melted or damaged.

5. Wet heat test: Place the sample at a temperature of 38-42℃, a relative humidity of 90%-95%, and a test cycle of 48 hours. After the test, perform Article 3, which should meet the requirements.

6. Cold and hot shock: Place the sample in a -18℃ low temperature box, keep it for 15 minutes, take it out and place it indoors for no less than 5 minutes, then place it in a TF-20℃ thermostat for 15 minutes, take it out and place it indoors for no less than 5 minutes. After 3 cycles of testing, perform Article 3 test, which should meet the requirements of Articles 8 and 9.

7. Internal resistance: Measured between the two lead wires within 15 minutes including the shell, the internal resistance of the sample should be less than 5mΩ.

8. Insulation resistance: After the sample is fused, the insulation resistance between the two leads measured with a 500V megohmmeter should be above 0.2MΩ.

9. Electrical strength: After the 4th test, 500V AC voltage is applied between the two leads for 1 minute, and no flashing or breakdown should occur.

10. Tension: Fix the sample and apply a 5Kg tension on the lead wire along the axial direction. After 10S, there should be no pulling or loosening.

11. Bending: Fix the sample and apply a force 6mm away from the shell. First bend the lead wire 45 degrees and return it to the initial position. There should be no breakage or cracking. (Only one end of the lead can be tested)

12. Appearance: The shell should be smooth, without cracks and mechanical damage; the lead should be bright, and the connection with the shell should be firm and not loose; the epoxy branch package should be smooth, without flow, and the lead should not be hanging on the branch.

Contact Us

Waiting for your email, we will reply you within 12 hours with valuable information you needed.

English

English العربية

العربية Български

Български 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά Magyar

Magyar Italiano

Italiano 日本語

日本語 한국어

한국어 Polski

Polski Português

Português Română

Română Русский

Русский Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Tiếng Việt

Tiếng Việt