Product Categories

Product Tags

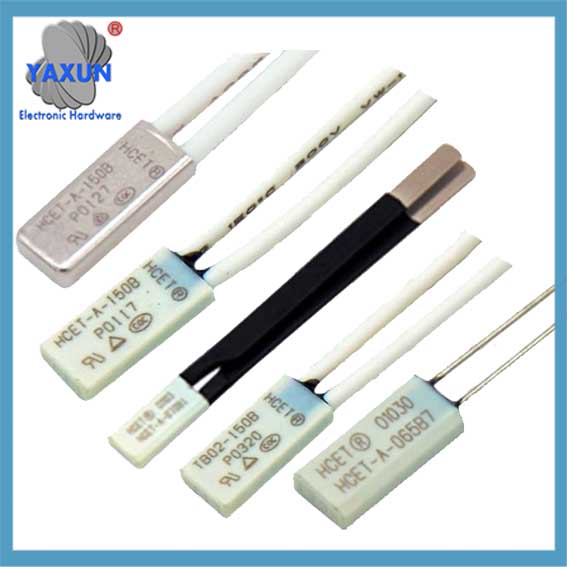

China Small Thermal Switches for Battery pack Temp Control

Custom world’s smallest size Temp Control Battery pack thermal switches (TB02, BW, KW) are equipped with an anti-static Temperature Limiter bimetal thermostat and current design, and one of the main advantages. As a result, itches with a long lifespan.

Custom world’s smallest size Temp Control Battery pack thermal switches (TB02, BW, KW) are equipped with an anti-static Temperature Limiter bimetal thermostat and current design, and one of the main advantages. As a result, itches with a long lifespan.

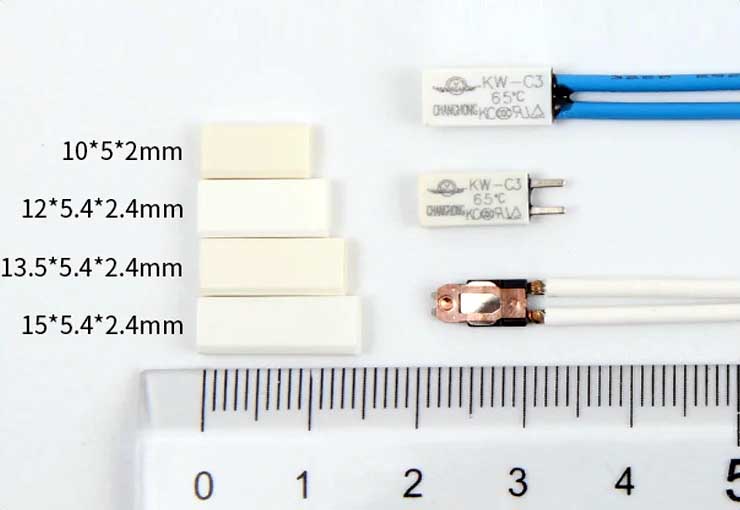

YAXUN thermal protecotor bimetal thermal switch, with very small size:14X5.2X2.2mm, 12X5.4X2.4mm.

Battery pack thermal protecotor bimetal thermal switch is of snap-action type and used for protection against over current and over temperature. It features very small size (12X5.4X2.4mm), and is widely used in notebook battery pack,mobil battery pack,power tool battery pack , electrical device and house-hold appliance.

1 Product use

KW series thermal protector is a product with temperature-sensitive characteristics. The product has the characteristics of advanced structure, small size, sensitive action, large electric shock capacity and long life. Widely used for overheat protection of fractional horsepower motors, electric appliances, fluorescent lamp ballasts, transformers, automobile motors, integrated circuits and general electrical equipment;

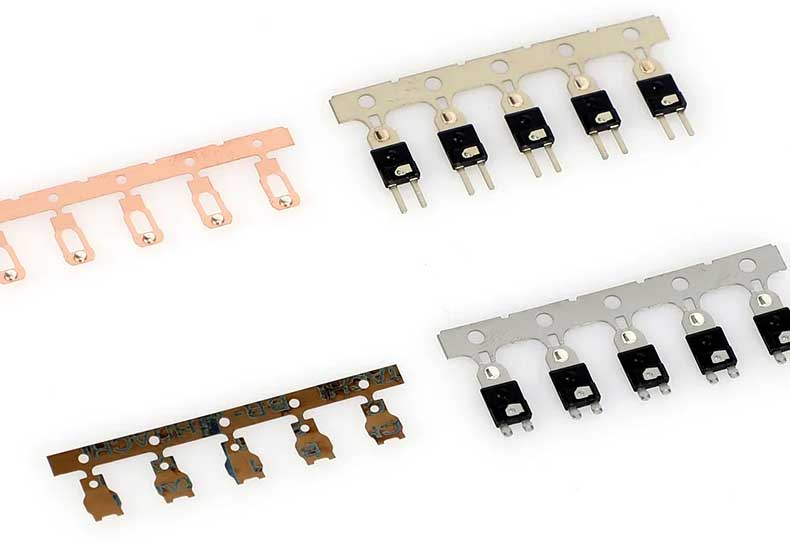

2 Structure

2.1 Appearance: The external dimensions meet the requirements of product drawings (see attached photos);

2.2 wire: The insulation layer is made of PVC, polyethylene material, silicone material, etc., with UL certified wires;

2.3 shell: PBT engineering plastic shell or metal shell plated with nickel and zinc alloy;

2.4 Casing material: PET polyester insulation sleeve or PE type sleeve meets the performance requirements of electrical appliances.

3 performance

3.1 Rated current:

VOLTAGE 12V-DC 24V-DC 120V-AC 250V-AC

CURRENT 0-12A 0-10A 0-10A 0-8A

3.2 Operating temperature: 30℃~155℃, tolerance ±5℃ (see attached table for details).

3.3 Lead wire tensile test: The lead wire of the thermal protector should be able to withstand a tensile force greater than or equal to 30N for 1min without breakage or looseness.

3.4 Insulation voltage:

a. The thermal protector should be able to withstand AC660V, 50Hz alternating current between the two leads after thermal disconnection. Test lasted 1min, no breakdown or flashover;

b. The terminal wire of the thermal protector and the surface of the insulating sleeve or the surface insulating type thermal protector shell can withstand AC1800V, 50Hz alternating current. Lasted 1min, no breakdown or flashover;

3.5 Insulation resistance: Under normal conditions, the insulation resistance between the wire and the insulation sleeve is above 100MΩ. (The meter used is a DC500V insulation resistance meter)

3.6 Contact resistance: When the thermal protector is closed, the contact resistance should not be greater than 50mΩ.

3.7 Heat resistance test:The product is placed in a 150°C environment for 96 hours.

3.8 Moisture resistance test: The product is placed in an environment at 40°C and a relative humidity of 95% for 48 hours.

3.9 Thermal shock test: The product is placed alternately in a 150℃, -20℃ environment for 30min each for 5 cycles.

3.10 Vibration resistance test: The product can withstand amplitude 1.5mm, frequency change 10~55HZ, scanning change period is 3~5min. Vibration direction X, Y, Z, continuous vibration for 2 hours in each direction.

3.11 Drop test: The product falls freely once from 200mm height.

3.12 Compression resistance: Custom thermal protector products that require vacuum impregnation are immersed in a sealed oil tank. After applying 2Mpa of pressure and keeping it for 24h.

3.7,3.8,3.9,3.10,3.11,3.12 After the test, the following conditions shall be met:

a. The change of operating temperature should be within ±7℃ of the initial value;

b. Contact resistance should be below 50mΩ;

c. The shape should be free of obvious deformation;

d. There is no crack damage on the wire;

e.. Insulation voltage should meet the requirements of 3.4;

f. Insulation resistance should meet the requirements of 3.5.

4 Life

a. Under the conditions of rated voltage, current and power factor of 0.7, the external heating source makes it operate 1000 times, and the following conditions should be met:

b. Operating temperature change should be within ±5℃ of initial value

c. Contact resistance should be below 50mΩ;

Continue the test to 5000 times, and its operating temperature needs to be normal.

Other Matters:

5.1 The heating rate of the operating temperature detection should be controlled to 1℃/1min;

5.2 The shell of the protector must not withstand strong impact and pressure during use;

5.3 Certification:

KC Certification:ZU02104-18001

UL Certification: E504551

CQC Certification: KW-A1 CQC19002213738

KW-A2 CQC19002214100

KW-C1,C2 CQC19002214401

KW-C3 CQC19002214516

TUV :50423386(Motor thermal protector) 、50423345(thermostat)

CE :50202381001(Motor thermal protector)、50202163001(thermostat)

5.4 Model specification:

KW-XX-XXX℃

5 This standard does not involve matters, or the customer has other requirements to set separately。

Table:KW series thermal protector operating temperature, reset temperature comparison table

| Action temperature | Reset temperature | Action temperature | Reset temperature |

| 30±4℃ | 20以上 | 105±5℃ | 70±15 |

| 35±4℃ | 25以上 | 110±5℃ | 75±15 |

| 40±5℃ | 25±10 | 115±5℃ | 75±15 |

| 45±5℃ | 30±10 | 120±5℃ | 80±15 |

| 50±5℃ | 35±10 | 125±5℃ | 85±15 |

| 55±5℃ | 35±10 | 130±5℃ | 90±15 |

| 60±5℃ | 40±10 | 135±5℃ | 90±15 |

| 65±5℃ | 45±12 | 140±5℃ | 100±15 |

| 70±5℃ | 45±15 | 145±5℃ | 105±15 |

| 75±5℃ | 50±15 | 150±5℃ | 105±15 |

| 80±5℃ | 55±15 | 155±5℃ | 110±15 |

| 85±5℃ | 55±15 |

The special specification can also be manufactured as request |

|

| 90±5℃ | 60±15 | ||

| 95±5℃ | 65±15 | ||

| 100±5℃ | 70±15 | ||

The thermal switch is small and easy to install. It has a fast temperature sensing speed and a quick and agile action, so you can use it with confidence.

Contact Us

Waiting for your email, we will reply you within 12 hours with valuable information you needed.

English

English العربية

العربية Български

Български 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά Magyar

Magyar Italiano

Italiano 日本語

日本語 한국어

한국어 Polski

Polski Português

Português Română

Română Русский

Русский Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Tiếng Việt

Tiếng Việt