Product Categories

Product Tags

Pt100 temperature sensor for military equipment

Aerospace: In the aerospace field, PT100 sensors are used to measure the temperature of liquid oxygen and liquid hydrogen combustion chambers, turbine engines, fuel cells, etc. of aircraft and spacecraft. High precision, high reliability and strong stability are required.

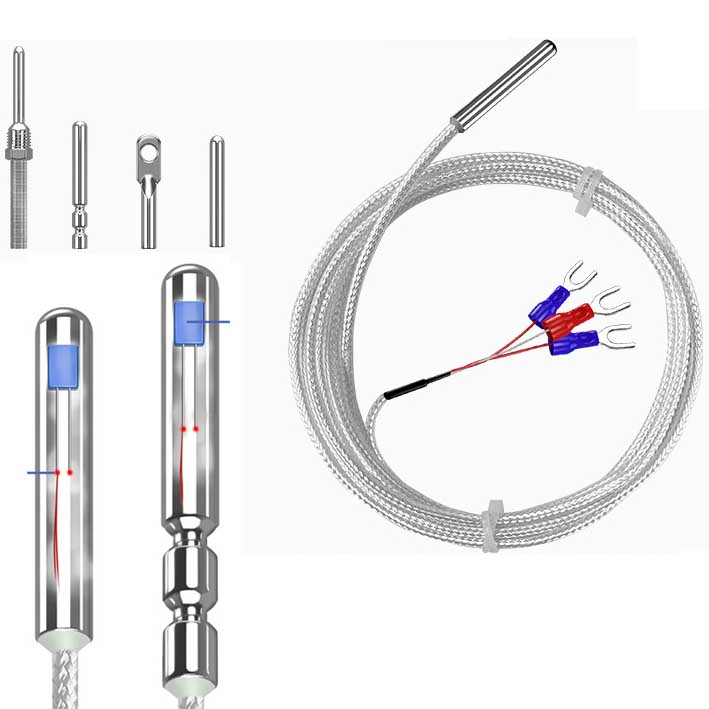

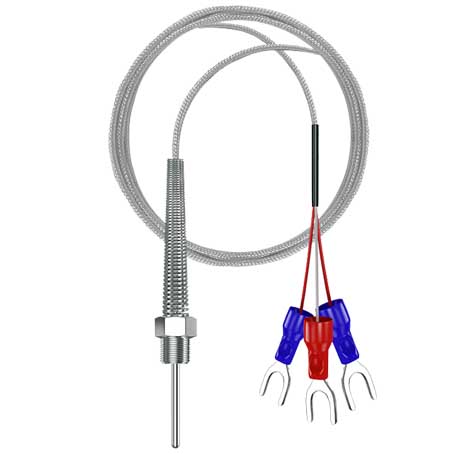

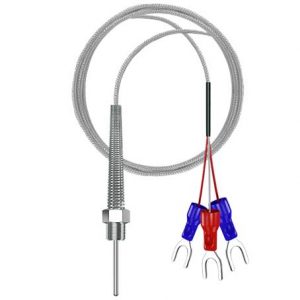

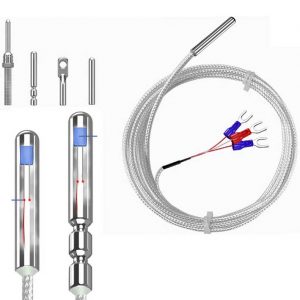

Pt100 / PT1000 sensor probes and wiring harnesses are widely used in military equipment, aviation, and aerospace equipment. The pt100 temperature sensor is an instrument that converts temperature variables into a standardized output signal that can be transmitted. It is mainly used for the measurement and control of industrial process temperature parameters. Transducers with sensors usually consist of two parts:

M6*1, M8*1.25, M10*1.5, M12*1, M14*1.5, M16*1.5, M20*1.5, M27*2 threaded pt100 temperature sensor

The PT100 sensor is a thermal resistor temperature sensor. Its working principle is to measure temperature by using the characteristic that the resistance of the conductor changes with temperature. In the PT100 sensor, the resistance value of pure platinum changes with temperature. When the temperature rises, the resistance value increases, and vice versa. Therefore, by measuring the resistance value of the PT100 sensor, the temperature of the measured object can be known.

PT100 sensors have the advantages of high precision, good stability, high reliability, and strong interchangeability, so they have been widely used in various fields. The following are some common application scenarios:

Industrial field: PT100 sensors are widely used in temperature measurement and control in industrial production processes, such as metallurgy, chemical industry, electricity, medicine and other fields. In high temperature, high pressure, and highly corrosive environments such as thermal power plants, nuclear power plants, and petrochemicals, PT100 sensors can stably and reliably measure temperature to ensure the smooth progress of the production process.

Automotive field: The temperature of components such as automobile engines, transmissions, and radiators needs to be accurately measured and controlled. PT100 sensors are widely used in temperature detection and control systems for automotive parts.

Aerospace: In the aerospace field, PT100 sensors are used to measure the temperature of liquid oxygen and liquid hydrogen combustion chambers, turbine engines, fuel cells, etc. of aircraft and spacecraft. High precision, high reliability and strong stability are required.

Agriculture: In greenhouse environments, PT100 sensors can be used to measure parameters such as soil temperature and air temperature. Provide precise temperature control and environmental monitoring for agricultural production.

Food: In food processing and storage, temperature is one of the key health and safety indicators. PT100 sensors can be used for temperature monitoring and control in food processing, refrigeration, warehousing and other links to ensure food quality and safety.

Medical: In medical equipment, such as medical thermostats, incubators, etc. PT100 sensors are also used in equipment that requires accurate measurement and control of system temperature.

In short, PT100 sensors, as a high-precision and high-stability temperature sensor, have been widely used in various fields. It has the advantages of wide temperature measurement range, high precision and good stability, and can provide reliable guarantee for temperature measurement and control of various equipment and systems.

PT100 sensor with high temperature resistant silver-plated shielded polyethylene wire

Indexing table

-50℃ 80.31 Ω

-40℃ 84.27 Ω

-30℃ 88.22 Ω

-20℃ 92.16 Ω

-10℃ 96.09 Ω

0℃ 100.00 Ω

10℃ 103.90 Ω

20℃ 107.79 Ω

30℃ 111.67 Ω

40℃ 115.54 Ω

50℃ 119.40 Ω

60℃ 123.24 Ω

70℃ 127.08 Ω

80℃ 130.90 Ω

90℃ 134.71 Ω

100℃ 138.51 Ω

110℃ 142.29 Ω

120℃ 146.07 Ω

130℃ 149.83 Ω

140℃ 153.58 Ω

150℃ 157.33 Ω

160℃ 161.05 Ω

170℃ 164.77 Ω

180℃ 168.48 Ω

190℃ 172.17 Ω

200℃ 175.86 Ω

composition part

Contact Us

Waiting for your email, we will reply you within 12 hours with valuable information you needed.

English

English العربية

العربية Български

Български 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά Magyar

Magyar Italiano

Italiano 日本語

日本語 한국어

한국어 Polski

Polski Português

Português Română

Română Русский

Русский Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Tiếng Việt

Tiếng Việt