Product Categories

Product Tags

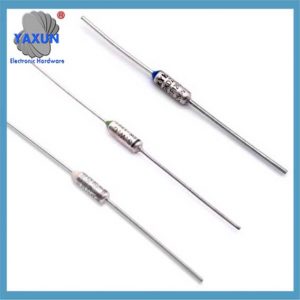

SEFUSE NEC SF Cutoffs Thermal Fuse OEM/ODM Service

How to tell if a sefuse NEC temperature fuse (Thermal Fuse) is good or bad?

The following steps can be used to measure the quality of a temperature fuse (Thermal Fuse) :

Use a multimeter to measure the resistance value: Set the multimeter to the resistance value measurement position, and then connect two test pens to the two ends of the Thermal Fuse . If the fuse is not blown, its resistance value should be very small. If the fuse is blown, the resistance value will be a larger number. If you are not sure about the correct resistance value, you can refer to the product manual or consult the manufacturer.

SF240E SEFUSE NEC Cutoffs Thermal Fuse OEM ODM Service |

SF96E SEFUSE Cutoffs NEC Thermal Fuse 99 Degree 10A 250V |

SCHOTT SEFUSE® – Reliable thermal fuses for the protection |

Observe the color change: If the Thermal Fuse turns black or the resistance value is abnormally high, it needs to be replaced.

The following matters need to be noted during the measurement process:

Lead bending: When bending the lead, it should be bent from a part more than 6 mm away from the root, and the root and lead should not be damaged. Do not forcibly pull, press, or twist the lead.

Welding operation: When welding the lead, the heating humidity should be limited to a minimum, and be careful not to apply high temperature to the thermal fuse. Do not forcibly pull, press, or twist the thermal fuse and lead. After welding, it should be cooled for more than 30 seconds immediately.

Use conditions: Thermal fuses can only be used under the conditions of specified rated voltage, current and specified temperature. Pay special attention to the maximum continuous temperature that the thermal fuse can withstand.

Additional suggestions and common problems:

Replacing fuses: When a thermal fuse burns out, it needs to be replaced with a new fuse with the same voltage and rated temperature. Usually, thermal fuses are designed to be push-pull, so you only need to gently pull out the old fuse and insert the new one.

Regular inspection: When using electrical appliances, electronic equipment, and automobiles, it is very important to regularly check whether the thermal fuse is burned out.

| Product Name | Thermal Fuse, Temperature Fuse, Thermal Cutoff |

| Body Material | Plastic, Ceramic, Metal |

| Rated Current | 1-30A |

| Rated Voltage | 250V |

| Lead Type | Axial, Radial |

| Temperature | 70C-260C |

| Application | Over-Temperature Protection |

Thermal cut-off fuses of different brands and types:

Black Square 250V Thermal Fuse Cutoff LED Fuses

250V Circuit Cut-off Temperature Thermal Fuse Ceramics

SEFUSE NEC SF Cutoffs Thermal Fuse

Contact Us

Waiting for your email, we will reply you within 12 hours with valuable information you needed.

English

English العربية

العربية Български

Български 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά Magyar

Magyar Italiano

Italiano 日本語

日本語 한국어

한국어 Polski

Polski Português

Português Română

Română Русский

Русский Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Tiếng Việt

Tiếng Việt