DS18B20 é um sensor de temperatura digital de 1 fio produzido por Dallas, com um pequeno pacote de 3 pinos para 92. A faixa de medição de temperatura é -55 ℃ ~+125 ℃, e pode ser programado para precisão de conversão A/D de 9 bits ~ 12 bits. A resolução de medição de temperatura pode atingir 0,0625 ℃, e a temperatura medida é emitida em série na forma de uma quantidade digital de 16 bits com extensão de sinal. Sua fonte de alimentação de trabalho pode ser introduzida na extremidade remota ou gerada pela fonte de alimentação parasitária. Vários DS18B20s podem ser conectados em paralelo a 3 ou 2 linhas. A CPU precisa apenas de uma linha de porta para se comunicar com muitos DS18b20s, ocupando menos portos do microprocessador, que podem economizar muitos leads e circuitos lógicos. As características acima tornam o DS18B20 muito adequado para sistemas de detecção de temperatura de vários pontos de longa distância.

2. Estrutura interna do diagrama de circuito DS18B20 DS18B20

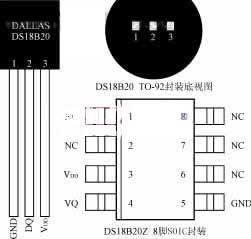

A estrutura interna do ds18b20 é mostrada na figura 1, que consiste principalmente de 4 peças: 64-bit rom, sensor de temperatura, O alarme de temperatura não volátil aciona TH e TL, e registros de configuração. O arranjo de pinos do DS18B20 é mostrado na figura 2. DQ é o terminal de entrada/saída de sinal digital; GND é o terreno de energia; VDD é o terminal de entrada da fonte de alimentação externa (fundamentado no modo de fiação de energia parasita, veja a figura 4).

O número de série de 64 bits na ROM é fotográfico antes de deixar a fábrica. Pode ser considerado como o código de sequência de endereço do DS18b20. O número de série de 64 bits de cada ds18b20 é diferente. O código de verificação de redundância cíclica (CRC = x8 + x5 + x4 + 1) da ROM de 64 bits está organizada. O papel da ROM é tornar cada DS18b20 diferente, para que vários ds18b20s possam ser conectados a um barramento.

Figura 1, Estrutura interna do DS18B20

O sensor de temperatura no ds18b20 completa a medição de temperatura, que é fornecido na forma de leituras binárias de complemento binário de 16 bits estendidas, expresso na forma de 0,0625 ℃/lsb, onde s é a parte do sinal. Por exemplo, A saída digital de +125 ℃ é 07d0h, A saída digital de +25.0625 ℃ é 0191h, A saída digital de -25.0625 ℃ é ff6fh, e a saída digital de -55 ℃ é FC90H.

23

22

21

20

2-1

2-2

2-3

2-4

Valor de temperatura Byte baixo

MSBLSB

S

S

S

S

S

22

25

24

Valor de temperatura Byte alto

O alarme de alta e baixa temperatura desencadeia TH e TL, e o registro de configuração é composto por um byte da EEPROM. Um comando de função de memória pode ser usado para escrever para o, Tl, ou o registro de configuração. O formato do registro de configuração é o seguinte:

0

R1

R0

1

1

1

1

1

MSBLSB

R1 e R0 determinam o número de dígitos de precisão para conversão de temperatura: R1r0 = “00”, 9-bit precisão, O tempo de conversão máxima é de 93,75ms; R1r0 = “01”, 10-bit precisão, O tempo de conversão máxima é de 187,5ms. R1r0 = “10”, 11-bit precisão, O tempo de conversão máxima é de 375ms. R1r0 = “11”, 12-bit precisão, O tempo de conversão máxima é de 750ms. O padrão é precisão de 12 bits quando não está programado.

O registro de alta velocidade é uma memória de 9 bytes. Os dois primeiros bytes contêm as informações digitais da temperatura medida; o 3º, 4th, e o 5º bytes são cópias temporárias do TH, Tl, e registros de configuração, respectivamente, e são atualizados toda vez que uma redefinição de energia ocorre; o 6º, 7th, e o 8º bytes não são usados e representados como todos os 1s lógicos; O 9º byte lê o código CRC de todos os anteriores 8 bytes, que pode ser usado para garantir a comunicação correta.

3. DS18B20 Sequência de trabalho

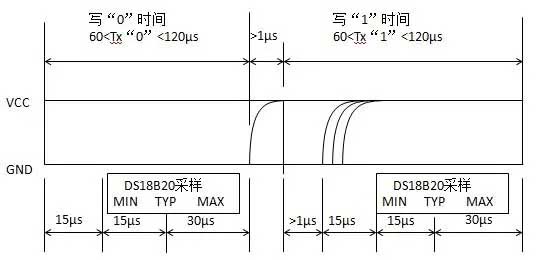

O fluxo de protocolo de trabalho de primeira linha do ds18b20 é: Inicialização → ROM Instruções de operação → Instruções de operação de memória → Transmissão de dados. Sua sequência de trabalho inclui sequência de inicialização, Escreva sequência e sequência de leitura, Como mostrado na figura 3 (um) (b) (c).

(um) Sequência de inicialização

(c) Leia sequência

Figura 3, Diagrama de sequência de trabalho DS18B20

4. Design típico da interface do DS18B20 e microcomputador de chip único

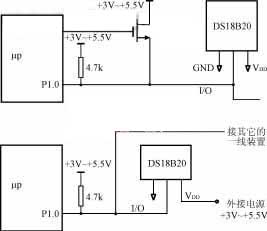

Figura 4 Leva o microcomputador de chip único da série MCS-51 como exemplo para desenhar a conexão típica entre DS18B20 e Microprocessador. Na figura 4 (um), O DS18B20 adota o modo de fonte de alimentação parasita, e seus terminais VDD e GND estão aterrados. Na figura 4 (b), O DS18B20 adota o modo de fonte de alimentação externa, e seu terminal VDD é alimentado por fonte de alimentação de 3V ~ 5,5V.

um) Modo de trabalho da fonte de alimentação parasita

(b) Modo de trabalho de fonte de alimentação externa

Figura 4 Diagrama de conexão típico de DS18b20 e microprocessador

Supondo que a frequência de cristal usada pelo sistema microcomputador de chip único seja de 12MHz, Três sub -rotinas são escritas de acordo com o tempo de inicialização, Escreva o tempo e leia o tempo do ds18b20: Init é a sub -rotina de inicialização; Escrever é o Write (comando ou dados) sub -rotina; Leia é a sub -rotina de dados de leitura. Todas as leituras e escrita de dados começam da parte mais baixa.

DateQup1.0

……

Init:Clrea

Unido:Setbdat

MOVR2, # 200

INI11:Clrdat

DJNZR2, INI11; O host envia um pulso de redefinição para 3μs × 200 = 600μs

Setbdat; O host libera o ônibus, e a linha da porta é alterada para entrada

MOVR2, # 30

In12:DJNZR2, INI12; Ds18b20 aguarda 2μs × 30 = 60μs

Clrc

Orlc,QUE; É a linha de dados DS18B20 (Pulse existe)?

Jcini10; Ds18b20 não está pronto, reinicializar

MOVR6, #80

INI13: Orlc, QUE

Jacini14; A linha de dados DS18B20 fica alta, A inicialização é bem -sucedida

DJNZR6, INI13; Linha de dados Baixo nível pode durar 3μs × 80 = 240ms

Sjmpini10; A inicialização falhou, reiniciar

INI14: Modr2, #240

In15: DJNZR2, NI15; DS18B20 responde por pelo menos 2μs × 240 = 48 0μs

Ret

;-------------------------

ESCREVER:Clrea

MOVR3, # 8;Laço 8 vezes, Escreva um byte

WR11:Setbdat

MOVR4, # 8

RRCA;Escreva movimentos de bit de um para cy

Clrdat

WR12:DJNZR4, WR12

;Aguarde 16μs

Movdat,C;A palavra de comando é enviada para ds18b20 bit a pouco

MOVR4, # 20

WR13:DJNZR4, WR1 3

; Verifique se o processo de gravação dura 60μs

DJNZR3, WR11

; Continue antes de enviar um byte

Setbdat

Ret

;------------------------

LER:Clrea

MOVR6, # 8; Laço 8 vezes, Leia um byte

RD11:Clrdat

MOVR4, # 4

Nop; Baixo nível dura 2μs

Setbdat; Defina a linha da porta como entrada

RD12:DJNZR4, RD12

; Aguarde 8μs

Movc,De t

;O host lê os dados do ds18b20 bit a pouco

RRCA;Os dados de leitura são movidos para um

MOVR5, # 30

RD13:DJNZR5, RD13

;Verifique se o processo de leitura dura 60μs

DJNZR6, RD11

;Depois de ler um byte de dados, Armazene -o em um

Setbdat

Ret

;-------------------------

O host deve seguir três etapas para controlar o DS18B20 para a conversão completa de temperatura: inicialização, ROM Instruções de operação, e instruções de operação de memória. DS18B20 deve ser iniciado para iniciar a conversão antes de ler o valor de conversão de temperatura. Assumindo que apenas um chip está conectado a uma linha, A precisão padrão de conversão de 12 bits é usada, e uma fonte de alimentação externa é usada, Uma sub -rotina getwd pode ser gravada para concluir uma conversão e ler o valor da temperatura.

Dotado:Lcallinit

MOVA,# 0CCH

Lcallwrite; Enviar Skip Rom Command

MOVA,# 44H

Lcallwrite; Enviar comando de conversão inicial

Lcallinit

MOVA,# 0CCH; Enviar Skip Rom Command

Lcallwrite

MOVA,# 0BH; Enviar comando de leitura de memória

Lcallwrite

Lcallread

MOVWDLSB,UM

; Envie baixo byte de valor de temperatura para WDLSB

Lcallread

MOVWDMSB,UM

; Envie alto byte de valor de temperatura para WDMSB

Ret

……

O alto byte de valor de temperatura lido pela sub -rotina getwd é enviado para a unidade WDMSB, e o byte baixo é enviado para a unidade WDLSB. Então, de acordo com o formato de representação do byte de valor de temperatura e seu bit de sinal, O valor real da temperatura pode ser obtido através de transformação simples.

Se vários ds18b20 estiverem conectados em uma linha, O modo de conexão da fonte de alimentação parasita é adotado, Configuração da precisão da conversão, Alarme de limite alto e baixo, etc.. são necessários. Então a escrita da sub -rotina getwd será mais complicada. Devido a limitações de espaço, Esta seção não será descrita em detalhes. Consulte o conteúdo relevante.

Aplicamos com sucesso DS18B20 ao “Banho de aquecimento doméstico” Sistema de controle que desenvolvemos. Sua velocidade de conversão rápida, alta precisão de conversão, E a interface simples com o microprocessador trouxe grande conveniência ao trabalho de design de hardware, reduzindo efetivamente os custos e diminuindo os ciclos de desenvolvimento.

English

English العربية

العربية Български

Български 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά Magyar

Magyar Italiano

Italiano 日本語

日本語 한국어

한국어 Polski

Polski Português

Português Română

Română Русский

Русский Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Tiếng Việt

Tiếng Việt