Categorias de Produtos

- Disjuntor térmico 20

- Porta-caixa de fusíveis 36

- Sensor de temperatura 67

- Interruptor térmico 64

- Fusível do carro 19

- Fusíveis aparafusados 7

- fusível térmico 32

- fusíveis de montagem em superfície 12

- termistor 22

- Suporte de fusível para montagem em PCB 27

- Chicote de fiação 6

- Porta-fusíveis de lâmina 17

- termostato 46

- Fusível elétrico 14

Etiquetas de produto

Postagens recentes

Corte térmico (TCO) é um componente de proteção de superaquecimento. When the temperature inside the device or system exceeds the preset safety value, the TCO disconnects the circuit to prevent damage to the device or fire. This type of fuse is often used in electronic equipment, automóveis, and industrial equipment to provide additional safety. This article summarizes the working principle, structural characteristics, process flow, selection parameters, and design considerations of the thermal fuse.

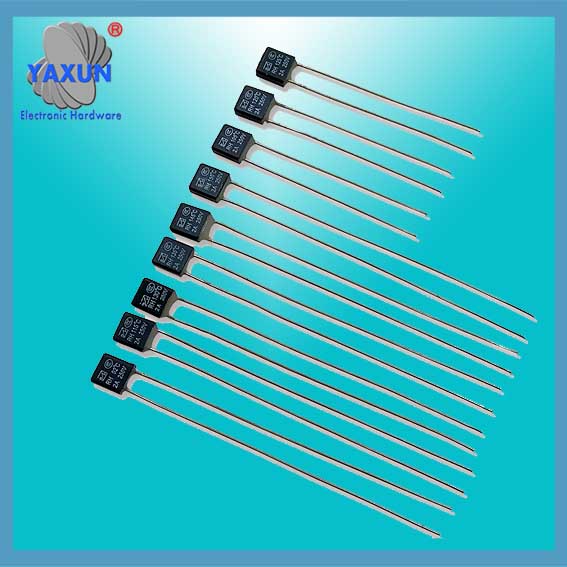

Tamura / Definir tipo de pino de fusível térmico

Notes on the installation of thermal fuse:

1. When using lead bending, it should be bent from a part more than 6 mm from the root; When bending, do not damage the roots and leads, and do not pull, imprensa, or twist the leads forcibly.

2. When the thermal fuse is fixed by screws, riveting or binding posts, it should be able to prevent mechanical creep and poor contact.

3. The connecting parts should be able to work reliably within the working range of the electrical product without displacement due to vibration and shock.

4. When welding the lead wire, the heating humidity should be limited to a minimum, and no high temperature should be applied to the thermal fuse; Do not forcibly pull, imprensa, or twist thermal fuses and leads; After welding, it should be cooled for more than 30 seconds immediately.

5. The thermal fuse can only be used under the conditions of the specified rated voltage, current and specified temperature. Pay particular attention to the maximum continuous temperature that the thermal link can withstand.

Observação: Nominal current, lead length and temperature can be Designed according to customer requirements.

N-F Series

Thermal Fuse Features

Fusing temperature thermal fuse accurate, high withstand voltage, tamanho pequeno, and temperature resistance.

Belonging unrecoverable type thermal fuses. Temperature fuse melting off, even if the surrounding temperature falls, it will not be turned on.

Use insulating housing.

No lead (Pb) and cadmium (Cd), and comply with RoHS.

REACH does not contain the specified 46 categories SVHC (SVHC).

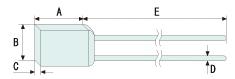

Thermal Fuse Size

TAMURA Thermal Fuse

| Comprimento do cabo | Dimensões (milímetros) | ||||

| UM | B | C | D | E | |

| Standard N-F | 4.1±0.1 | 5.2±0.1 | 2.0±0.1 | 0.53±0.05 | 36±3.0 |

| Long N-F(eu) | 4.1±0.1 | 5.2±0.1 | 2.0±0.1 | 0.53±0.05 | 68±3.0 |

| Modelo | Rated temperature Tf(℃) |

Temperatura operacional (℃) |

Corrente nominal (A) |

Tensão nominal (V) |

maintaining the temperature Th(℃) |

Maximum temperature limit Tm(℃) |

| N06F | 65 | 61± 3 | 1.0 | AC250 | 50 | 200 |

| N0F | 76 | 72± 3 | 1.0 | AC250 | 50 | 200 |

| N1F | 86 | 81± 2 | 1.0 | AC250 | 60 | 200 |

| N2F | 102 | 98± 3 | 1.0 | AC250 | 75 | 200 |

| N3F | 115 | 111± 2 | 1.0 | AC250 | 95 | 200 |

| N4F | 127 | 123± 2 | 1.0 | AC250 | 105 | 200 |

| N13F | 133 | 129± 3 | 1.0 | AC250 | 105 | 200 |

| N5F | 136 | 131± 2 | 1.0 | AC250 | 100 | 200 |

| N6F | 139 | 134± 2 | 1.0 | AC250 | 110 | 200 |

| N7F |

Contate-nos

Aguardando seu e-mail, responderemos dentro de 12 horas com informações valiosas que você precisava.

English

English العربية

العربية Български

Български 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά Magyar

Magyar Italiano

Italiano 日本語

日本語 한국어

한국어 Polski

Polski Português

Português Română

Română Русский

Русский Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Tiếng Việt

Tiếng Việt