Detectores de temperatura de resistência (IDT) são um tipo de sensor de temperatura que são amplamente utilizados em uma variedade de aplicações industriais devido à sua precisão, repetibilidade, e estabilidade. Esses dispositivos medem a temperatura sentindo a mudança de resistência quando a temperatura de um material muda.

A principal diferença entre 2-, 3-, e os sensores RTD de 4 fios estão na maneira como lidam com a resistência dos fios de conexão, com 2 fios sendo o menos preciso, pois inclui a resistência ao fio na medição, 3-o fio compensa parcialmente para isso, e 4 fios elimina completamente a resistência ao fio, fornecendo a maior precisão, mas também sendo o mais complexo e caro de implementar; Fazendo de 3 fios a opção mais usada para aplicações industriais.

2-WIR RTD:

Design mais simples, menos caro.

Mede a resistência do elemento RTD e dos fios de conexão, levando a leituras imprecisas, especialmente com comprimentos de fio longos.

Adequado para aplicações onde alta precisão não é crítica.

3-WIR RTD:

Usa um fio extra para compensar parcialmente a resistência dos fios de conexão.

Oferece melhor precisão em comparação com 2 fios, tornando -o o mais comumente usado em ambientes industriais.

Fornece um bom equilíbrio entre precisão e custo.

4-WIR RTD:

Considerado a configuração mais precisa, pois isola completamente a resistência do elemento RTD dos fios de conexão.

Requer um circuito mais complexo e é frequentemente usado em aplicações de laboratório, onde é necessária alta precisão.

Pontos -chave para lembrar:

Precisão: 4-arame > 3-arame > 2-arame

Custo: 2-arame < 3-arame < 4-arame

Aplicativo: 2-fio para aplicações básicas, 3-fio para a maioria dos usos industriais, 4-fio para medições de alta precisão

As sondas RTD estão disponíveis em uma variedade de configurações, incluindo 2 fios, 3-arame, e modelos de 4 fios. Existem diferenças significativas entre esses tipos que devem ser considerados ao selecionar o dispositivo apropriado para um aplicativo.

Fatores a serem considerados

Ao escolher entre 2 fios, 3-arame, e sensores RTD de 4 fios, Existem vários fatores a considerar, incluindo:

Fatores ambientais

Certos fatores ambientais, como altos níveis de ruído elétrico ou interferência, pode criar interferência que pode causar erros de medição.

Requisitos de aplicação

Aplicações diferentes requerem diferentes limiares de precisão. É absolutamente essencial que o sensor forneça precisão suficiente para um aplicativo específico.

Restrições orçamentárias

Ao escolher um RTD para qualquer aplicativo específico, O custo é uma consideração importante. Porque a configuração de 4 fios envolve mais componentes, 4-Os RTDs de arame tendem a ser mais caros que os RTDs de 2 ou 3 fios.

Tipos de configuração do fio RTD

Como um circuito RTD é configurado determina com que precisão a resistência do sensor é calculada e quanta resistência externa no circuito pode distorcer a leitura de temperatura.

Cada um dos três tipos de configuração, 2-arame, 3-arame, e 4 fios, tem suas próprias vantagens e desvantagens, e escolher o certo depende do aplicativo. Ao entender as características de cada configuração, Engenheiros e técnicos podem garantir que o sensor RTD seja usado de maneira mais eficaz.

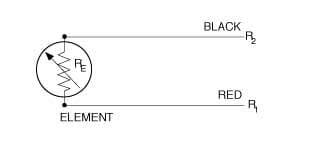

2-Configuração de fio de RTD

A configuração RTD de 2 fios é a mais simples dos projetos de circuito RTD. Nesta configuração serial, Um único chumbo conecta cada extremidade do elemento RTD ao dispositivo de monitoramento. Como a resistência calculada para o circuito inclui a resistência entre os fios e o conector RTD, bem como a resistência no elemento, O resultado sempre conterá algum grau de erro.

Os círculos representam os limites do elemento nos pontos de calibração. A resistência RE é retirada do elemento resistor, e esse valor nos dará uma medição precisa de temperatura. Infelizmente, Quando fazemos uma medição de resistência, o instrumento indicará rtotal:

Onde rt = r1 + R2 + R3

Isso produzirá uma leitura de temperatura mais alta do que a leitura de temperatura medida real. Embora este erro possa ser reduzido usando leads e conectores de teste de alta qualidade, é impossível eliminá -lo completamente.

Portanto, A configuração RTD de 2 fios é mais útil quando usada com sensores de alta resistência ou em aplicações onde não é necessária uma precisão muito alta.

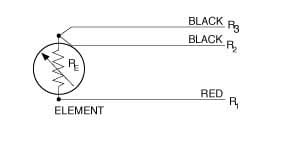

3-Configuração de fio de RTD

A configuração de RTD de 3 fios é o design de circuito RTD mais comumente usado e é frequentemente visto em processos industriais e em aplicações de monitoramento. Nesta configuração, Dois fios conectam o elemento de detecção ao dispositivo de monitoramento em um lado do elemento de detecção e um fio o conecta do outro lado.

Se três fios do mesmo tipo forem usados e são iguais em comprimento, então r1 = r2 = r3. Medindo a resistência dos leads 1 e 2 e o elemento resistivo, a resistência total do sistema (R1 + R2 + RÉ) é medido.

Se a resistência também for medida através de leads 2 e 3 (R2 + R3), nós só temos a resistência dos leads, e como todas as resistências de chumbo são iguais, subtraindo esse valor (R2 + R3) da resistência total do sistema ( R1 + R2 + RÉ) folhas apenas re, e uma medição de temperatura precisa foi feita.

Como este é um resultado médio, A medição só será precisa se todos os três fios tiverem a mesma resistência.

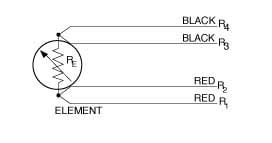

4-Configuração de fio de RTD

Essa configuração é a mais complexa e, portanto, a mais demorada e cara para instalar, Mas produz os resultados mais precisos.

A tensão de saída da ponte indica indiretamente a resistência à RTD. A ponte requer quatro fios de conexão, uma fonte de alimentação externa, e três resistores com um coeficiente de temperatura zero. Para impedir que os três resistores de ponte sejam submetidos à mesma temperatura que o sensor RTD, O RTD é isolado da ponte por um par de fios de extensão.

Esses fios de extensão reproduzem o problema que encontramos inicialmente: A resistência dos fios de extensão afeta a leitura de temperatura. Este efeito pode ser minimizado usando uma configuração de ponte de três fios.

Em uma configuração de RTD de 4 fios, Dois fios conectam o elemento de detecção ao dispositivo de monitoramento em ambos os lados do elemento de detecção. Um conjunto de fios fornece a corrente para medição, e o outro conjunto de fios mede a queda de tensão no resistor.

Com a configuração de 4 fios, o instrumento oferece uma corrente constante (EU) através de leads externos 1 e 4. A ponte RTD Wheatstone cria uma relação não linear entre mudanças na resistência e mudanças na tensão de saída da ponte. A já não linear-resistência à resistência à RTD é ainda mais complicada pela necessidade de uma equação adicional para converter a tensão de saída da ponte na impedância equivalente a RTD.

A queda de tensão é medida nos leads internos 2 e 3. Portanto, de v = ir, nós sabemos apenas a resistência do elemento, não afetado pela resistência ao chumbo. Esta é apenas uma vantagem sobre a configuração de 3 fios se diferentes leads forem usados, que raramente é o caso.

Este design de ponte de 4 fios compensa totalmente toda a resistência nos leads e os conectores entre eles. A configuração RTD de 4 fios é usada principalmente em laboratórios e outros ambientes onde é necessária alta precisão.

2-Configuração do fio com circuito fechado

Outra opção de configuração, Embora raro hoje, é a configuração padrão de 2 fios com um loop fechado de fios ao lado. Esta configuração funciona da mesma forma que a configuração de 3 fios, mas usa um fio adicional para realizar isso. Um par separado de fios é fornecido como um loop para fornecer compensação pela resistência ao chumbo e variações ambientais na resistência ao chumbo.

Conclusão

As configurações de RTD são uma ferramenta valiosa na indústria – capaz de atender à maioria dos requisitos de precisão. Com a seleção de configuração correta, As sondas RTD podem fornecer medições precisas que são confiáveis e repetíveis em uma variedade de ambientes severos. Para alcançar os melhores resultados, É importante entender completamente os diferentes tipos de configurações de arame disponíveis e selecionar o que melhor atende às necessidades do aplicativo. Com a configuração certa, Os sensores RTD são capazes de fornecer medições de temperatura precisas e confiáveis.

English

English العربية

العربية Български

Български 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά Magyar

Magyar Italiano

Italiano 日本語

日本語 한국어

한국어 Polski

Polski Português

Português Română

Română Русский

Русский Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Tiếng Việt

Tiếng Việt