In today’s era, the rapid development of society has brought us convenience while also bringing hidden dangers to our health. The number of sub-healthy people is increasing, and the scale of the pharmaceutical industry is expanding rapidly, which has brought considerable pressure to the logistics industry. În special, the particularity of medicines means that if the protective measures are not properly taken during transportation, serious economic losses will be caused. According to data, pharmaceutical logistics has always been the main body of huge capital flow. According to data, the value of the global pharmaceutical logistics market will reach 118.9 billion US dollars in 2027. Especially now that the aging of the population has become serious and the number of medical treatment has increased, the situation faced by medicines in transportation/storage will become more severe.

The impact of temperature and humidity on the quality of medicines:

Medicines start from pharmaceutical factories, are transported through the “cold chain”, arrive at hospitals/pharmacies, and finally come to us in the circulation market. Among them, after many procedures, the temperature and humidity during storage in the middle, if there are slight errors, the quality of medicines will decline in the light, and the medicines will directly fail in the heavy. Such medicines used on patients may cause a medical accident. In recent years, there have been many diseases and disasters, and the world is in this situation, and the transportation of vaccines has become a top priority. But what is a headache is that from 2007 la 2021, there will be transportation accidents every once in a while. The unified reason is that the temperature and humidity during transportation are not up to standard, which causes damage to medicines.

Accidents that occur in the “cold chain” of medicines.

The most typical one is the “vaccine case”. Tian Jianguo, the protagonist of this case, believes that there may be no problem if the vaccine is not refrigerated, but in the eyes of insiders, this is a major transportation accident. These vaccines are transported to various places in the province, and the refrigerated trucks that transport medicines have been broken. If such vaccines are used on patients, the results will be disastrous.

De fapt, not only vaccines, but in the entire pharmaceutical industry, the rigor of the transportation process directly determines the quality of medicine use. Cu toate acestea, how can we ensure the quality of medicines in “cold chain” transportation and save economic losses?

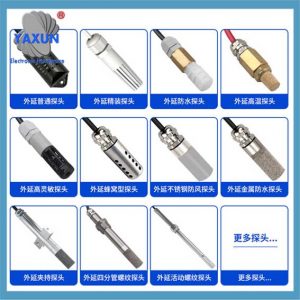

În acest moment, some people will think of using temperature and humidity sensors. That’s right, but the traditional temperature and humidity sensors only have the function of collecting data. Although they can meet the basic needs of understanding data, they cannot perform real-time operations. In order to meet various situations during transportation, we can choose different temperature and humidity sensors according to the scene.

How to use temperature and humidity sensors in the “cold chain”?

During transportation:

In areas with large batches and concentrated delivery areas, we can use multi-probe temperature and humidity recorders to collect data. The temperature and humidity sensors in the temperature and humidity recorder can collect and analyze data using GPRS/4G to transmit the data to the cloud platform in the management personnel’s equipment for 24-hour uninterrupted monitoring, which is convenient for management personnel to view at any time. During the transportation of the “cold chain” transport vehicle, the temperature and humidity value storage time interval of the temperature and humidity recorder can be set at will from 1 la 60 minute, and the operation is flexible. When the temperature in the carriage exceeds the limit, the management personnel will be reminded by sound or SMS. When the intermediate signal is interrupted and it is inconvenient to upload data, the temperature and humidity recorder will first store the local data, and when the signal is restored, it will automatically upload to the cloud platform synchronously, which is convenient and fast.

Storage of medicines during cold chain transportation:

The temperature and humidity recorder in the incubator is adjusted according to the different temperature and humidity storage requirements of different medicines. During the cold chain transportation process, the medicine will be equipped with an incubator, which is equipped with a temperature and humidity sensor to monitor the temperature in the box at any time. Traditional incubators are suitable for transporting ordinary medicines. They use cold chain incubators + refrigerants. The effects vary and cannot be monitored in real time. If emergency medicines, blood, reagents or refrigerated products are transported, incubators equipped with GSM-GPRS/4G data transmission functions are recommended, which are convenient for managers to monitor at any time. When the temperature in the box exceeds or exceeds the limit, the alarm system can also be triggered to remind managers to make adjustments in time.

Pharmaceutical warehouse storage:

The country has detailed regulations on pharmaceutical warehousing, and the warehouse environment needs to be monitored in real time. It is difficult to achieve this standard with manpower alone, which requires the use of an automatic temperature and humidity monitoring system to complete this task. După cum sugerează și numele, the temperature and humidity sensor is the core of the entire system. The temperature and humidity sensor collects information about the surrounding environment and transmits the information to the management host. Through analysis and calculation, the host obtains the final data and uploads it to the cloud platform, which is convenient for managers to view in real time 24 hours a day.

Temperature and humidity sensors play an important role in the entire pharmaceutical “cold chain”. From pharmaceutical production, to factory delivery, transportation, and finally to the hands of patients, they will appear. Whether it is a factory, refrigerated truck, incubator, warehouse, pharmacy freezer, etc., as long as there are temperature and humidity measurement tools, the contribution of temperature and humidity sensors is indispensable. If the “operating host” in the pharmaceutical “cold chain” is regarded as the brain, then the temperature and humidity sensor is equivalent to its “nerve”. Without these terminal monitoring nerves to collect data, the body cannot work correctly.

. One of the few domestic source industries with chip design capabilities: 5 brevete de invenție, 27 utility models, și 2 undisclosed technologies

. Domestic 0.6mm minimum size packaging technology

. Domestic full-size fully automatic single-ended glass sealing machine, single-ended thermistor tester

. Domestic dual temperature point (valoarea B) diode thermistor tester, achieving 0.3% accuracy for medical and military use.

English

English العربية

العربية Български

Български 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά Magyar

Magyar Italiano

Italiano 日本語

日本語 한국어

한국어 Polski

Polski Português

Português Română

Română Русский

Русский Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Tiếng Việt

Tiếng Việt