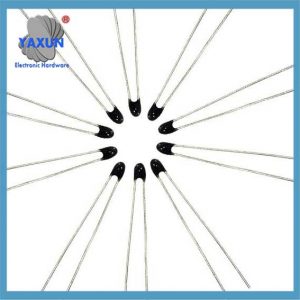

La selectarea unui termistor, este într-adevăr necesar să se ia în considerare în mod cuprinzător mulți parametri cheie și ambalaje (Încapsulare cu rășini epoxidice, Încapsulare cu mărgele de sticlă, Încapsulare cu peliculă subțire, Încapsulare SMD, Senzor sonda din otel inoxidabil Incapsulare, ABS waterproof injection plastic). Să vă spun în detaliu:

Resistance-temperature characteristics: This is the core characteristic of the thermistor. The resistance changes with temperature. La selectare, it is necessary to clarify the change in resistance at different temperatures, adică, the temperature coefficient, to ensure the response speed and sensitivity of the thermistor in a specific application.

Measurement temperature range: According to the application requirements, determine the temperature range that the thermistor can safely and effectively measure to avoid exceeding its measurement capabilities.

Power consumption: The power consumption during operation must meet the requirements of the application circuit to prevent excessive power consumption from causing circuit instability.

Time constant: Reflects the response speed of the thermistor to temperature changes. La selectare, it is necessary to consider whether it meets the needs of the application scenario.

stabilitate: Stability in long-term use is crucial, which determines whether the thermistor can maintain its performance for a long time.

Packaging and size: Choose the appropriate packaging and size according to the application space and installation requirements to ensure smooth installation and use.

Price: Choose products with moderate cost based on cost-effectiveness.

What are the requirements for the packaging materials of NTC thermistors?

There are many requirements for the packaging materials of NTC thermistors. Let me tell you about it!

În primul rând, we have to know that the packaging material must be able to protect the thermistor and prevent it from being disturbed by the external environment. Common packaging materials include epoxy resin, sticlă, etc.

Epoxy resin packaging, it has good insulation properties, adhesion and corrosion resistance, and can effectively protect NTC thermistors. În plus, the surface of the thermistor encapsulated with epoxy resin is smooth and burr-free, which looks very delicate! This packaging form is widely used in temperature measurement, compensation and control, as well as high-precision instrumentation and other fields.

Let’s talk about glass packaging. This type of NTC thermistor has the characteristics of small size, Precizie înaltă, raspuns rapid, and anti-aging. Due to the high temperature and moisture resistance of glass packaging, it is particularly suitable for use in harsh environments such as high temperature and humidity. în plus, glass packaging is also convenient for automated installation, which improves production efficiency!

Desigur, in addition to these two common packaging materials, there are other packaging forms, such as columnar packaging, Ambalare SMD, etc. Each packaging form has its unique characteristics and applicable occasions, and we have to choose according to specific needs.

Aşa, when choosing the packaging material of the NTC thermistor, we have to comprehensively consider factors such as application requirements, working environment and performance requirements. În acest fel, we can choose the most suitable packaging form to ensure that the thermistor can work stably and accurately!

English

English Afrikaans

Afrikaans العربية

العربية বাংলা

বাংলা bosanski jezik

bosanski jezik Български

Български Català

Català 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Hrvatski

Hrvatski Čeština

Čeština Nederlands

Nederlands Eesti keel

Eesti keel Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά हिन्दी; हिंदी

हिन्दी; हिंदी Magyar

Magyar Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Latviešu valoda

Latviešu valoda Lietuvių kalba

Lietuvių kalba македонски јазик

македонски јазик Bahasa Melayu

Bahasa Melayu Norsk

Norsk پارسی

پارسی Polski

Polski Português

Português Română

Română Русский

Русский Cрпски језик

Cрпски језик Slovenčina

Slovenčina Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Українська

Українська اردو

اردو Tiếng Việt

Tiếng Việt