Kategorije izdelkov

- Termični odklopnik 20

- Nosilec škatle z varovalkami 36

- Temperaturni senzor 67

- Termično stikalo 64

- Avtomobilska varovalka 19

- Pritrjene varovalke 7

- toplotna varovalka 32

- površinsko nameščene varovalke 12

- termistor 22

- Nosilec varovalk za PCB 27

- Kabelski snop 6

- Držala rezilnih varovalk 17

- termostat 46

- Električna varovalka 14

Oznake izdelkov

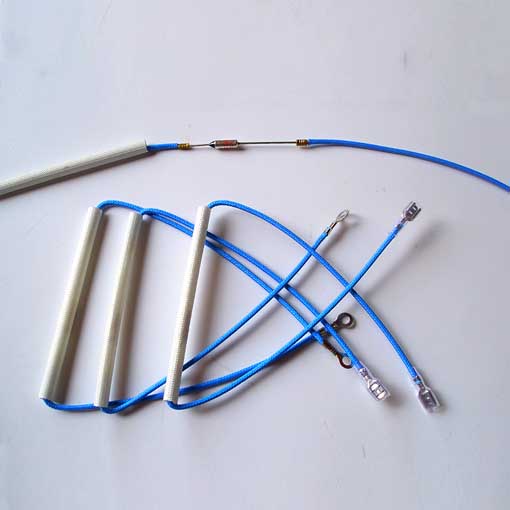

Po meri vgrajena termična varovalka in kabel

Termična varovalka je toplotna zaščita. Termične varovalke so v glavnem sestavljene iz talin in cevi, plus zunanja polnila. Pri uporabi, povežite toplotno varovalko zaporedno z zaščitenim tokokrogom. Ko tok zaščitenega vezja preseže določeno vrednost, in po določenem času, talina, ki jo ustvari talina sama, zlije talino, prekinitev tokokroga, s čimer zaščitite vezje. Električne naprave, ki za prekinitev tokokroga uporabljajo kovinski vodnik kot talino, so v tokokrogu povezane zaporedno.

The Built thermal fuse is a thermal protector. Temperature Fuse link cable are mainly composed of melts and tubes, plus zunanja polnila. Pri uporabi, connect the thermal fuse link cable in series with the protected circuit. Ko tok zaščitenega vezja preseže določeno vrednost, in po določenem času, talina, ki jo ustvari talina sama, zlije talino, prekinitev tokokroga, s čimer zaščitite vezje. Električne naprave, ki za prekinitev tokokroga uporabljajo kovinski vodnik kot talino, so v tokokrogu povezane zaporedno. When an overload or short-circuit current passes through the melt, the melt itself will heat up and melt. Zato, it has played a certain role in protecting the power system, various electrical equipment and household appliances. With anti-delay characteristic, when the overload current is small, the fusing time is long; When the overload current is large, the fusing time is short. Zato, within a certain range of overload current until the current returns to normal, the thermal fuse Wire harness will not blow and can continue to be used. The Temperature Fuse link is mainly composed of a melt, a housing and a support. Med njimi, hot melt is the key element to control the fusing characteristics.

In the import and export tariffs, they are classified as 8535 oz 8536.

princip delovanja

A metal conductor is used as a melt in series in the circuit. When an overload or short-circuit current flows through the melt, it is fused because of its own heat, thereby breaking the circuit. Temperature Fuse link are simple in structure and easy to use. They are widely used as protection devices in power systems, various electrical equipment and household appliances.

Lastnosti

The rated fuse current is not equal to the rated current of the fuse. The rated current of the melt is selected according to the load current of the protected equipment. The rated current of the fuse shall be greater than the rated current of the fuse, and shall be determined in cooperation with the main electrical appliance.

The Built Temperature Fuse link cable is mainly composed of a melt, a housing and a support. Med njimi, the melt is the key component to control the fusing characteristics. The material, size and shape of the melt determine the fusing characteristics. Melt materials are divided into two types, low melting points and high melting points. Low-melting materials such as lead and lead alloys have low melting points and are easy to melt. Because of its large resistivity, the cross-sectional size of the melt is large, and more metal vapor is generated during melting. Only for fuses with low breaking capacity. High melting point materials such as copper and silver have high melting points and are not easy to melt. Vendar, due to its low resistivity, it can be made smaller in cross-section size than a low melting point melt, and less metal vapor is generated during melting. Suitable for fuses with high breaking capacity. The shape of the melt is divided into two types: filament and ribbon. Changing the shape of the variable cross section can significantly change the fuse characteristics of the fuse.

Thermal fuses have anti-delay characteristics, to je, when the overload current is small, the fuse time is long; When the overload current is large, the fusing time is short. Zato, within a certain overload current range, when the current returns to normal, the thermal fuse link cable will not blow and can continue to be used. Thermal fuse link cable have various different fuse characteristic curves, which can be adapted to the needs of different types of protection objects.

effect

Electrical components installed in a circuit to ensure safe operation of the circuit. When the circuit is faulty or abnormal, the current is constantly increasing, and the increased current may damage some important or valuable components in the circuit, ali lahko zažge vezje ali celo povzroči ogenj. If the thermal fuse link cable is correctly installed in the circuit, the thermal fuse link will fuse itself to cut off the current when the current abnormally rises to a certain height and a certain time. So as to protect the safe operation of the circuit. Thermal cutoff cuts off the current, s tem varovanje varnega delovanja vezja.

Inter-level cooperation

In order to prevent over-level fusing and expand the scope of the accident, there should be good coordination between the thermal fuse link of the upper and lower levels (ie, power supply trunks and branch lines). When selecting, the fuse rated current of the upper stage (power supply main line) thermal fuse link cable should be 1 do 2 stages larger than that of the lower stage (power supply branch line). Commonly used thermal fuses are tubular thermal fuses R1 series, Spiral thermal fuse RLl series, Packed closed thermal fuse link RT0 series and fast thermal fuse RSO, RS3 series, itd.

Thermal fuse wire for small household appliances

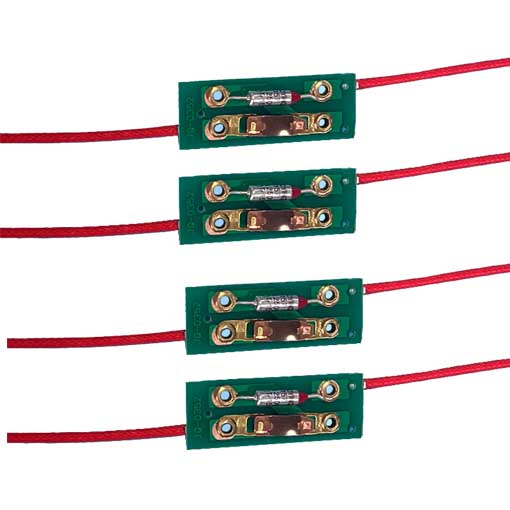

Thermal switch and thermal fuse harness assembly for heater

Termični vložek varovalke in kabel

Related introduction

Use and maintenance

Thermal fuse in low-voltage power distribution system is an electrical appliance that plays a role in safety protection. Thermal fuse link cable are widely used in power grid protection and electrical equipment protection. When short circuit or overload occurs in the power grid or electrical equipment, the circuit can be automatically cut off to avoid damage to electrical equipment and prevent accidents from spreading.

Thermal fuse is composed of insulating base (or support), stiki, melt and so on. The fuse is the main working part of the fuse. The melt is equivalent to a special wire connected in series in the circuit. When the circuit is short-circuited or overloaded, the current is too large, and the melt melts due to overheating, s tem odrezanje vezja. The melt is often made into filaments, grids or flakes. Melt materials have the characteristics of low relative melting point, stable characteristics and easy melting. Generally use lead-tin alloy, silver-plated copper sheet, zinc, silver and other metals. In the process of melting and cutting off the circuit, an arc will be generated. In order to extinguish the arc safely and effectively, the melt is generally installed in the fuse housing, and measures are taken to quickly extinguish the arc.

Fuses have the advantages of simple structure, convenient use, and low price, and are widely used in low-voltage systems.

Temperature fuse Brand: TAMURA / Tamura, Albemarle, NEC, Emerson, Panasonic / Matsushita, Xingyu, JingKe, PANASONIC

Najprej, the design and operation principle of a Temperature Fuse

● Temperature Fuse has detected abnormal temperature and cut off the circuit function. It can detect the temperature of household or industrial electrical products abnormal rise in temperature and quickly cut off the circuit, can be achieved to prevent the effects of fire in unburned.

● temperature fuse wire type with axial and radial lead type two. Using a thermal particles (organic matter).

● Safety Certification: UL, CSA, VDE, BEBA, PSE, JET, CQC ... certificate, EU ROHS environmental directives

● Current Product: 1A, 2A, 3A, 5A, 10A, 15A, 20A

Second, the application of various types of household appliances products; such as iron, hair dryer (hair dryer), pečica, straight hair, sesalniki, Električni grelniki, electric fans Juicers, blenders, napajalniki, motorji, printers, copiers, fax machine, HID ballasts, fluorescent lighting ballasts, transformatorji, charger, battery pack, heating appliances, Električni grelniki, kuhalniki riža, electric thermos, lončki za kavo, ventilation fans, fans, sewing machines, grelniki vode, power converter , power plugs and sockets, hladilniki, klimatske naprave, car air conditioners, instruments, equipment, and so do overheat protection.

| model | Rated operating temperature (Tf) | Actual operating temperature (Ct) | Maintaining the temperature (Th) | Limit temperature (Tm) | Nazivna napetost (ur) |

| RF90 | 90℃ | 86±3 ℃ | 55℃ | 180℃ | 250V |

| RF100 | 100℃ | 96±3 ℃ | 68℃ | 180℃ | 250V |

| RF110 | 110℃ | 105±3 ℃ | 75℃ | 180℃ | 250V |

| RF115 | 115℃ | 110±3 ℃ | 75℃ | 180℃ | 250V |

| RF120 | 120℃ | 116±3 ℃ | 85℃ | 180℃ | 250V |

| RF125 | 125℃ | 121±3 ℃ | 90℃ | 180℃ | 250V |

| RF130 | 130℃ | 125±3 ℃ | 92℃ | 180℃ | 250V |

| RF135 | 135℃ | 131±3 ℃ | 95℃ | 180℃ | 250V |

| RF140 | 140℃ | 136±3 ℃ | 100℃ | 180℃ | 250V |

| RF145 | 145℃ | 141±3 ℃ | 105℃ | 180℃ | 250V |

| RF150 | 150℃ | 146±3 ℃ | 113℃ | 180℃ | 250V |

| RF155 | 155℃ | 150±3 ℃ | 113℃ | 200℃ | 250V |

| RF158 | 158℃ | 155±3 ℃ | 113℃ | 200℃ | 250V |

| RF160 | 160℃ | 157±3 ℃ | 125℃ | 200℃ | 250V |

| RF165 | 165℃ | 161±3 ℃ | 125℃ | 200℃ | 250V |

| RF170 | 170℃ | 165±3 ℃ | 125℃ | 230℃ | 250V |

| RF172 | 172℃ | 167±3 ℃ | 135℃ | 230℃ | 250V |

| RF175 | 175℃ | 170±3 ℃ | 135℃ | 230℃ | 250V |

| RF180 | 180℃ | 177±3 ℃ | 140℃ | 230℃ | 250V |

| RF185 | 185℃ | 181±3 ℃ | 148℃ | 230℃ | 250V |

| RF188 | 188℃ | 184±3 ℃ | 148℃ | 230℃ | 250V |

| RF190 | 190℃ | 187±3 ℃ | 148℃ | 230℃ | 250V |

| RF192 | 192℃ | 189±3 ℃ | 155℃ | 230℃ | 250V |

| RF195 | 195℃ | 192±3 ℃ | 155℃ | 250℃ | 250V |

| RF200 | 200℃ | 197±3 ℃ | 160℃ | 280℃ | 250V |

| RF210 | 210℃ | 205±3 ℃ | 172℃ | 280℃ | 250V |

| RF216 | 216℃ | 212±3 ℃ | 175℃ | 280℃ | 250V |

| RF230 | 230℃ | 227±3 ℃ | 185℃ | 300℃ | 250V |

| RF240 | 240℃ | 235±3 ℃ | 190℃ | 300℃ | 250V |

| RF250 | 250℃ | 247±3 ℃ | 208℃ | 320℃ | 250V |

Kontaktirajte nas

Čakam na vašo e-pošto, vam bomo odgovorili v roku 12 ure z dragocenimi informacijami, ki jih potrebujete.

English

English العربية

العربية Български

Български 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά Magyar

Magyar Italiano

Italiano 日本語

日本語 한국어

한국어 Polski

Polski Português

Português Română

Română Русский

Русский Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Tiếng Việt

Tiếng Việt