Kategorije izdelkov

- Termični odklopnik 20

- Nosilec škatle z varovalkami 36

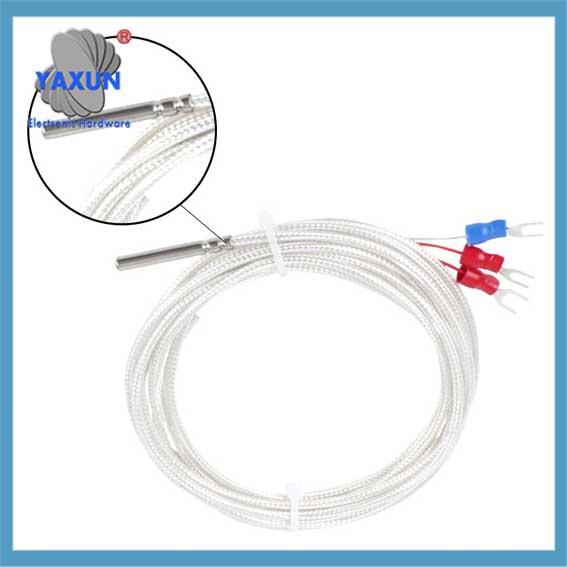

- Temperaturni senzor 67

- Termično stikalo 64

- Avtomobilska varovalka 19

- Pritrjene varovalke 7

- toplotna varovalka 32

- površinsko nameščene varovalke 12

- termistor 22

- Nosilec varovalk za PCB 27

- Kabelski snop 6

- Držala rezilnih varovalk 17

- termostat 46

- Električna varovalka 14

Oznake izdelkov

NTC, PTC, PT100, DS18B20 za senzorje temperaturne sonde

Termočlenska sonda: Za merjenje temperature uporablja termoelektrični učinek, in ima značilnosti širokega merilnega območja in hitre odzivne hitrosti.

Sonda toplotne odpornosti: za merjenje temperature uporablja lastnost, da se odpornost kovinskih ali polprevodniških materialov spreminja s temperaturo, in ima značilnosti visoke merilne natančnosti in dobre stabilnosti.

Polprevodniška sonda: za merjenje temperature uporablja lastnost, da se prevodnost polprevodniških materialov spreminja s temperaturo, in ima značilnosti majhne velikosti, majhna teža in nizka poraba energije.

NTC, PTC, PT100, DS18B20 Temperature probes and temperature sensors play an important role in the field of temperature measurement. The following is a detailed introduction to temperature probe sensors:

There are many types of temperature sensors, vključno z:

Thermocouples

These sensors are made of two dissimilar metals that connect at two points to form a junction. They are reliable, accurate, and can operate over a wide range of temperatures.

Detektorji temperature odpornosti (RTD)

These sensors are based on the change in resistance of a metal as the temperature changes.

Thermistors

These sensors use the temperature characteristics of semiconductor resistors, which change resistance as the temperature changes. Thermistors are sensitive and have high accuracy relative to their cost.

Negativni temperaturni koeficient (NTC) termistorji

These sensors are sensitive and can respond to very small temperature changes. They have a temperature range of -50 ° C do 250 °C.

Resistive temperature detectors

These sensors have positive temperature coefficients (PTC) and offer precise temperature measurements. Vendar, they have poor sensitivity.

1. Definition and working principle

Temperature probe:

Definition: A temperature probe is a device specifically used to measure temperature, and its core component is a temperature-sensitive element.

Delovno načelo: A temperature probe uses sensitive elements (such as thermocouples, toplotni upori, polprevodniki, itd.) to convert temperature changes into electrical signals for subsequent circuit processing or display.

Temperature sensor:

Definition: A temperature sensor is a broader concept that includes a temperature probe and a signal processing circuit connected to it.

Delovno načelo: A temperature sensor not only includes a sensitive element, but also has a signal processing circuit that can complete the acquisition, obdelava in izhod temperaturnih signalov, usually in the form of digital or analog signals.

2. Types and characteristics

Temperature probe type:

Termočlenska sonda: Za merjenje temperature uporablja termoelektrični učinek, in ima značilnosti širokega merilnega območja in hitre odzivne hitrosti.

Sonda toplotne odpornosti: za merjenje temperature uporablja lastnost, da se odpornost kovinskih ali polprevodniških materialov spreminja s temperaturo, in ima značilnosti visoke merilne natančnosti in dobre stabilnosti.

Polprevodniška sonda: za merjenje temperature uporablja lastnost, da se prevodnost polprevodniških materialov spreminja s temperaturo, in ima značilnosti majhne velikosti, majhna teža in nizka poraba energije.

Temperature sensor type:

Analog temperature sensor: outputs analog signals, which need to be converted into digital signals by analog-to-digital converters for subsequent processing.

Digital temperature sensor: directly outputs digital signals, has strong anti-interference ability, high accuracy, and is easy to integrate into the control system.

Intelligent temperature sensor: has self-diagnosis, samokalibracija, communication and other functions, in lahko uresničimo daljinsko spremljanje in nadzor.

3. Selection and application

Selection factors:

Application environment: Razmislite, ali ima izmerjeno okolje posebne pogoje, kot je jedkost, visoka temperatura, visok tlak, itd., tako da izberete ustrezne materiale in raven zaščite.

Merilno območje: Izberite ustrezen senzor glede na območje temperature, ki jo je treba izmeriti, da se zagotovi, da lahko senzor natančno izmeri znotraj potrebnega območja.

Accuracy requirements: According to the accuracy requirements of the application for temperature measurement, select a sensor with corresponding accuracy.

Cost budget: Under the premise of ensuring performance, consider cost factors and choose cost-effective sensors.

Application areas:

Industrijska avtomatizacija: used to monitor temperature changes in industrial equipment, machines and production processes to ensure normal operation of equipment and product quality.

Medical industry: used in medical equipment, temperature monitoring instruments and drug storage equipment to monitor patient temperature, ambient temperature and drug storage conditions.

Avtomobilska industrija: used in electric vehicle motors, capacitors, DC converters, charging systems, as well as automobile engines, gearboxes, air conditioning systems and exhaust systems to monitor and control the temperature of various liquids and gases.

Agriculture and food processing industry: used in agricultural greenhouses, cold storage, food processing equipment and transport vehicles to monitor and control the temperature of agricultural products and food.

Other fields: such as air conditioning and refrigeration industry, military and aerospace industry, Internet of Things industry, itd. are also widely used.

IV. Use and maintenance

Installation: Install the sensor correctly according to the installation instructions to ensure good contact between the sensor and the object to be measured and avoid measurement errors caused by improper installation.

Wiring: Pravilno priključite signalno črto in daljnovo linijo senzorja, da zagotovite stabilnost in natančnost prenosa signala.

Kalibracija: Senzor redno kalibrirajte, da zagotovite, da njegova natančnost merjenja ustreza zahtevam uporabe. The calibration process usually involves placing the sensor in a known temperature environment, comparing the difference between its output value and the standard value, and making necessary adjustments.

Matriatenja: Redno čistite in vzdržujte senzorja, da se izognete prahu, umazanija, itd. that affect the measurement performance of the sensor. Hkrati, pay attention to check whether the cable connection is loose or damaged, and replace damaged parts in time.

Če povzamemo, temperature probe sensors have a wide range of applications and an important position in the field of temperature measurement. When selecting and using them, it is necessary to make comprehensive considerations based on the specific application scenarios and requirements to ensure the accuracy and reliability of the measurement results. If you have any other questions or need further help, please feel free to let me know.

Kontaktirajte nas

Čakam na vašo e-pošto, vam bomo odgovorili v roku 12 ure z dragocenimi informacijami, ki jih potrebujete.

English

English العربية

العربية Български

Български 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά Magyar

Magyar Italiano

Italiano 日本語

日本語 한국어

한국어 Polski

Polski Português

Português Română

Română Русский

Русский Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Tiếng Việt

Tiếng Việt