Kategorije izdelkov

- Termični odklopnik 20

- Nosilec škatle z varovalkami 36

- Temperaturni senzor 67

- Termično stikalo 64

- Avtomobilska varovalka 19

- Pritrjene varovalke 7

- toplotna varovalka 32

- površinsko nameščene varovalke 12

- termistor 22

- Nosilec varovalk za PCB 27

- Kabelski snop 6

- Držala rezilnih varovalk 17

- termostat 46

- Električna varovalka 14

Oznake izdelkov

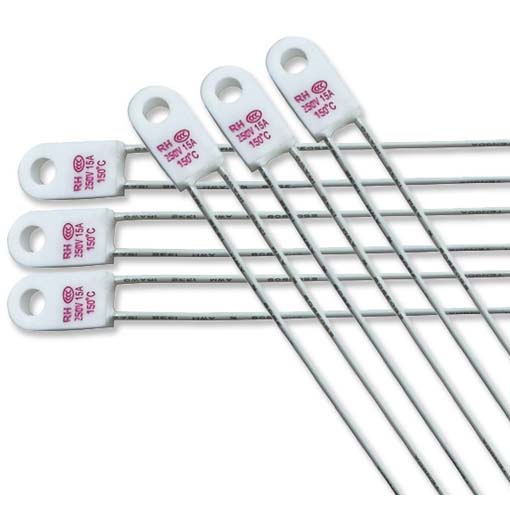

Set square Thermal Limit Cutoffs Fuse use for Coffee maker

NASTAVI / sedi / RY / Uchibashi The thermal fuse is a thermal protection device designed for electronic equipment to provide overheating protection. It adopts a tubular structure, and the spiral melt material is an alloy, which has the characteristics of fast melting. The model of this fuse is BF216, which is small in size and suitable for a variety of electronic equipment.

NASTAVI / sedi / RY / Uchibashi The thermal fuse is a thermal protection device designed for electronic equipment to provide overheating protection. It adopts a tubular structure, and the spiral melt material is an alloy, which has the characteristics of fast melting. The model of this fuse is BF216, which is small in size and suitable for a variety of electronic equipment.

Certification and use: The thermal fuse has passed UL, VDE, PSE, CCC, CUL, ROHS and other international safety standards certification, and is suitable for electronic equipment.

Tehnični parametri: Its maximum voltage is 250V, the maximum current is 10A, and the holding current is also 10A. The operating temperature is set at 191℃, and the temperature control range is 73~240℃. The limit temperature can reach 380℃, showing its excellent thermal protection ability.

Scope of use: Temperature fuses are widely used in small household appliances, large household appliances, office appliances, household appliance accessories and electronic components, providing a reliable solution for overheat protection of these devices.

Lastnosti: The fuse adopts a fully sealed structure to ensure that its fusing system is stable and reliable, and is not affected by harsh environments such as external humidity. It is sensitive to external temperature, has accurate operating temperature, majhna velikost, zaprta struktura, reliable performance, and has been certified by multiple international safety standards.

These characteristics of the temperature fuse make it an indispensable overheat protection component in electronic equipment, providing effective technical support for ensuring equipment safety and extending service life.

Notes on the installation of thermal fuse:

1. When using lead bending, it should be bent from a part more than 6 mm from the root; When bending, do not damage the roots and leads, and do not pull, Press, or twist the leads forcibly.

2. When the thermal fuse is fixed by screws, riveting or binding posts, it should be able to prevent mechanical creep and poor contact.

3. The connecting parts should be able to work reliably within the working range of the electrical product without displacement due to vibration and shock.

4. When welding the lead wire, the heating humidity should be limited to a minimum, and no high temperature should be applied to the thermal fuse; Do not forcibly pull, Press, or twist thermal fuses and leads; After welding, it should be cooled for more than 30 seconds immediately.

5. The thermal fuse can only be used under the conditions of the specified rated voltage, current and specified temperature. Pay particular attention to the maximum continuous temperature that the thermal link can withstand.

Opomba: Nominal current, lead length and temperature can be Designed according to customer requirements.

N-F Series

Lastnosti

1.EXCELLENTLY sensitive to ambient temperature

We select Copper Alloy for heat conductor to ensure the thermal response get the high performance

2.Stable and Precise operation

We select high quality chemical to ensure the operating is always in Rated Temperature+0℃/-5℃

3.En strel operacija

4.Longer working life

ARLIN ® thermal links (TF is over 200℃) has great working life performance

ARLIN ® F00/F01/F0X Series is a compact and reliable one-shot thermal links designed to protect widely electrical appliances from high temperature or other risks.

F series thermal cutoff applies metal as case, heat sensible particles(organske kemikalije)as heat sent sensor. F series thermal cutoff has very low internal resistance and very good electrical endurance due to solid alloy material as contact material applied.

Funkcije izdelka

Fusing temperature thermal fuse accurate, high withstand voltage, majhna velikost, and temperature resistance.

Belonging unrecoverable type thermal fuses. Temperature fuse melting off, even if the surrounding temperature falls, it will not be turned on.

Use insulating housing.

No lead (Pb) and cadmium (Cd), and comply with RoHS.

REACH does not contain the specified 46 categories SVHC (SVHC).

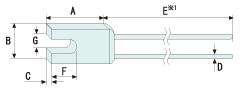

Product Size

Set square Thermal Limit Cutoffs

| Dolžina kabla | Dimensions (mm) | ||||

| A | B | C | D | E | |

| Standard N-F | 4.1±0,1 | 5.2±0,1 | 2.0±0,1 | 0.53±0.05 | 36±3.0 |

| Long N-F(L) | 4.1±0,1 | 5.2±0,1 | 2.0±0,1 | 0.53±0.05 | 68±3.0 |

| Model | Rated temperature Tf(℃) |

Delovna temperatura (℃) |

Nazivni tok (A) |

Nazivna napetost (V) |

maintaining the temperature Th(℃) |

Maximum temperature limit Tm(℃) |

| H06F | 65 | 61±3 | 2.5 | AC250 | 50 | 200 |

| H0F | 76 | 72±3 | 2.5 | AC250 | 50 | 200 |

| H1F | 86 | 81±2 | 2.5 | AC250 | 60 | 200 |

| H2F | 102 | 98±3 | 3.0 | AC250 | 75 | 200 |

| H3F | 115 | 111±2 | 3.0 | AC250 | 95 | 200 |

| H4F | 127 | 123±2 | 3.0 | AC250 | 100 | 200 |

| H13F | 133 | 129±3 | 3.0 | AC250 | 100 | 200 |

| H5F | 136 | 131±2 | 3.0 | AC250 | 100 | 200 |

| H6F | 139 | 134±2 | 2.5 | AC250 | 110 | 200 |

| H7F | 145 | 140±2 | 2.0 | AC250 | 115 | 200 |

Kontaktirajte nas

Čakam na vašo e-pošto, vam bomo odgovorili v roku 12 ure z dragocenimi informacijami, ki jih potrebujete.

English

English العربية

العربية Български

Български 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά Magyar

Magyar Italiano

Italiano 日本語

日本語 한국어

한국어 Polski

Polski Português

Português Română

Română Русский

Русский Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Tiếng Việt

Tiếng Việt