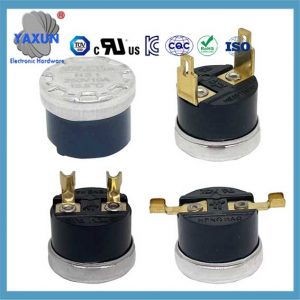

Kitajsko po meri bimetalno stikalo za toplotno disk ima namestitev površinskega pritrditve in vtičnika PCB. Pregrevanje preklopno stikalo (Bimetalni termostat) so naprave, zasnovane za varovanje komponent v situacijah, ko pride do previsoke temperature. Seznam izbranih površinskih toplotnih stikal in specifikacij izdelka termične zaščite, podatkovni listi, proizvajalci & dobavitelji.

Termično stikalo Bimetalnega diska na površini so nepogrešljive komponente v varnem in učinkovitem delovanju motorjev/ električnih naprav. S preprečevanjem pregrevanja, Zaščitijo električne naprave od škode, podaljšajo njihovo življenjsko dobo, zmanjšati nevarnost požara, zagotoviti varno delovanje, ter čim bolj zmanjšati čas izpada in stroške vzdrževanja. Nadalje, Termično stikalo za bimetalni disk pomaga pri izpolnjevanju varnostnih standardov v industriji, zagotavlja brezskrbnost upravljavcem in zainteresiranim stranem. Ker tehnologija napreduje, Toplotno stikalo se še naprej razvija, ponuja natančnejšo in zanesljivejšo zaščito motorjev v številnih aplikacijah.

Z razvojem tehnologije, obseg uporabe motorja je vedno bolj obsežen, vedno bolj pomembna je tudi uporaba motorja v vsakdanjem življenju in proizvodnji. Zgodi pa se tudi nesreča z vžigom motorja, v resničnem življenju, izgorevanje motorja je v glavnem posledica naslednjega pregrevanja blokirane tuljave, obremenitev je prevelika preobremenitev motorja, pomanjkanje faze in drugi razlogi. Namestitev toplotnega zaščitnika je eden od učinkovitih načinov za zaščito motorja. toplotno stikalo, imenovano tudi temperaturno stikalo, stikalo za nadzor temperature, itd. Je neke vrste temperaturno stikalo z bimetalno pločevino kot elementom za zaznavanje temperature, ko električna naprava normalno deluje, bimetalna pločevina je v prostem stanju, stik je v odklopljenem stanju, ko temperatura naraste na vrednost delovne temperature, bimetalni element se segreje, da povzroči notranjo napetost in hitro delovanje, odprite kontakt, prekiniti/poveži tokokrog, da bi igrali vlogo bimetalnega toplotnega stikala. Počakajte, da se temperatura okolice spusti na temperaturo zaščitnika, kontakt bo ponovno zaprl priključeno vezje, in motor bo spet delal.

Izbira desnega toplotnega stikala

Kako izbrati desnega vezja, ki je izklopljeno bimetalno stikalo, sicer ne samo, da ne more igrati zaščitne vloge, vendar bo povzročil, da motor ne bo deloval zaradi napačne izbire, ali celo zažgejo.

1. Napetost & Trenutna odločnost

• Toplotno stikalo bimetalnega diska ima različne napetostne razpone 400V 380V 230V 220V 110V, DC Motors bodo imeli tudi 36V 24V 12V, itd., Glede na različne delovne napetosti za izbiro različnih nazivnih zaščitnikov napetosti, načeloma, dejanska napetost je manjša ali enaka nazivni napetosti zaščite, na primer, 380V Motor ne more izbrati nazivne napetosti 220V zaščitnika, in nazivno napetost 220V zaščitnik se lahko uporablja v 110V motorju;

• Tok motorjev električnih naprav je razdeljen na tri vrste začetnega toka, normalni delovni tok in blokirani tok, Nazivni tok zaščitnika mora biti večji od največje vrednosti treh tokov, in je treba pustiti rob. Na primer, normalni delovni tok motorja 1A, začetni tok 1,5A, blokirni tok 2A, potem je nazivni tok izbranega zaščitnika vsaj 2a, in najbolje je izbrati nazivni tok 3A ali 5A, da ohranite rezervo. Nekateri začetni tok motorja je večji od nazivnega toka zaščitnika, vendar je začetni čas krajši, in normalni delovni tok in blokirni tok sta manjša od nazivnega toka zaščitnika, v tem primeru, lahko izberete tudi to zaščito. Ker je začetni tok večji od nazivnega toka, ampak zaradi kratkega časa, Toplotni učinek toka ni imel časa, da bi dvojno toploto, ki vodi do zaščite zaščitnika, da ne bi prišlo do napake.

2. Izberite za toplotno preklapljanje temperature

• Izbira temperature toplotnega stikala je povezana s tremi dejavniki: Stopnja izolacije emajlirane žice, Namestitveni položaj in vrsta zaščite.

Temperatura toplotnega stikala je nižja od najvišje dovoljene temperature, na primer, Najvišja temperatura izklopljenega razreda je 155 ℃, in dejanski izbor je lahko 145 ℃ ali 150 ℃.

• Položaj namestitve je razdeljen na vgrajen znotraj tuljave in v paketu zunaj tuljave, Ker ko je motor blokiran in posredovan toplota, Pregrevalni pojav se širi od znotraj in zunaj. Če je zaščitnik pokopan v notranjosti, Temperatura toplotnega stikala je nekoliko nižja od najvišje temperature emajlirane žice; Če je vezan zunaj tuljave, Razmislite o temperaturni razliki med notranjo in zunaj, in izberite zaščitnico z nižjo temperaturo. Na primer, Raven izolacije je f emajlirane žice razreda, Tuljava znotraj in zunaj temperaturne razlike 20 ℃, nato izberite 155-20 = 135 ℃ ali približno tako zaščitnika;

Motor Protector ima zaščitne funkcije, kot je preobremenitev, fazna odpoved, neravnovesje, premajhna, ozemljitev/puščanje, in stojnico. Lahko tvori zaščitno enoto za krmiljenje motorja z električnimi komponentami, kot so kontaktorji in zaganjalniki motorja. Ima funkcije, kot je daljinski avtomatski nadzor, Neposredni nadzor na kraju samem, indikacija plošče, signalni alarm, in komunikacija na terenu.

3. Izbira življenjske dobe toplotnega stikala

Različne testne zaklep motorja Različne zahteve za življenjsko dobo zaščitnika niso enake, kot je običajna zaklepanje gospodinjskega motorja 18 dnevi, Število ciklov ponastavitve normalnega delovanja ne bo preseglo 100000 krat, Nazivna življenjska doba napetostnega toka več kot 100000 krat lahko izberete zaščitnika; Samo nekateri motorji črpalk 3 dnevi blokiranja, načeloma, Življenjska zahteva je stokrat.

4. Izbira toplotnega stikala za tesnjenje

Motorna tuljava v postopku termičnega stikala bo potopila barvo, da bi izboljšala izolacijsko zmogljivost postopka, DIP barva je razdeljena na kapljico, potopitev, vakuum v barvo in druge procese, še posebej vakuum v tlak barve je velik, Izolacijsko barvo je enostavno vstopiti v notranjost zaščitnika, kar ima za posledico odpoved zaščitnika. Serija elektronike ST01 ima zelo visoko tesnjenje, pod pogojem -0.08MP, Stopnja potapljanja barve lahko doseže 3%; V primeru -0.03MP, Hitrost barve lahko doseže manj kot eno od desetih tisoč.

Parametri zaščite motorja

| Tehnični parametri

Pomožno napajanje |

Tehnični kazalci | |||

| ARD2(L) | Ard2f | ARD3 | ||

| Pomožno napajanje | Napetost | AC85V ~ 265V/DC100V ~ 350V | ||

| Napetost | ≤7va | ≤15VA | ||

| Nazivna delovna napetost | AC380V/AC660V,50Hz/60Hz | |||

| Ocenjeni obratovalni tok | 1A (0,1 ~ 9999) | |||

| 5A (0,1 ~ 9999) | ||||

| 1.6A (0,4a ~ 1,6a) | ||||

| 6.3A (1,6a ~ 6.3a) | ||||

| 25A (6.3a ~ 25A) | ||||

| 100A (25a ~ 100A) | ||||

| 250A (63A ~ 250A) | ||||

| 800A (250a ~ 800A) | ||||

| Kapaciteta kontaktne kontaktne releje | AC250V/ 3A;DC30V/ 3A | AC250V/ 6A | ||

| Vhod preklopa | 2-pot | 9-pot | ||

| Okolje | Delovna temperatura: -10° C ~ 55 ° C. | |||

| Temperatura skladišča: -20° C ~ 65 ° C. | ||||

| Relativna vlaga: 5﹪~ 95 ﹪ brez kondenzacije | ||||

| Višina: ≤ 2000m | ||||

| Raven onesnaženja | 2 | |||

| Raven zaščite | Ip20 | Glavna enota IP20 Prikazovalna enota IP45 | ||

| Namestitvena kategorija | Stopnja III | |||

Zaščita bimetalnega motorja

| Tehnični parametri | Tehnični kazalci | ||

| Pomožni napajalnik ARD3T | AC/DC 110 / 220V ali AC 380V,Poraba energije≤15VA | ||

| Delovna napetost z oceno motorja | AC 380V / 660V,50Hz / 60Hz | ||

| Delovni tok z motorjem | 1.6(0,40a-2.00a) | Izmerjeno z merilnim modulom | |

| 6.3(1.6a-6.3a) | |||

| 25(6.3A-25A) | |||

| 100(25A-100A) | |||

| 250(63A-250A) | Uporaba zunanjega toka transformatorja + merilni modul | ||

| 800(250A-800A) | |||

| Puščanje toka | 50M-1A | Z uporabo merilnega modula + Transformator toka puščanja | |

| 3A-30A | |||

| Kapaciteta kontaktne kontaktne releje | Uporovna obremenitev | AC250V、6A;DC24V、6A | |

| Induktivna obremenitev | AC250V、2A;DC24V、2A | ||

| Glavni vhod in izhod | 4Od、4Naredi,DI je lahko suho ali mokro vozlišče | ||

| Stikalni modul | 4Od、3Naredi,DI je lahko suho ali mokro vozlišče | ||

| Temperaturni modul | Vrsta zunanjega senzorja:PT100、PT1000、Cu50、PTC、NTC

Število senzorskih kanalov: 3 Ustrezen merilni razpon senzorja: PT100/PT1000:-50° C ~+500 ° C. Cu50:-50° C ~+150 ° C. PTC/NTC:100Oh ~ 30k |

||

| Analogni modul | Lahko realiziramo: 2-pot 4 ~ 20mA vhodna meritev, 2-pot 4 ~ 20mA prenosna izhod

4~ 20mA vhodna meritve natančnost ± 0,5% 4~ 20mA izhodna največja zmogljivost obremenitve je ≤500Ω |

||

| Glavna komunikacija | RS485:Modbus-ru | ||

| Komunikacijski modul | RS485:Dvojni modbus-rtu、Profibus | ||

| Okolje | Delovna temperatura | -10ºC ~ 55 ° C. | |

| Temperatura skladišča | -25ºC ~ 65 ° C. | ||

| Relativna vlaga | ≤95 ﹪ Brez kondenzacije, Brez jedkega plina | ||

| Višina | ≤2000m | ||

| Raven onesnaženja | Ravni 3 | ||

| Raven zaščite | Glavno telo IP20, Modul razdeljenega zaslona IP45 (Nameščeno na omari) | ||

| Namestitvena kategorija | Stopnja III | ||

English

English العربية

العربية Български

Български 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά Magyar

Magyar Italiano

Italiano 日本語

日本語 한국어

한국어 Polski

Polski Português

Português Română

Română Русский

Русский Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Tiếng Việt

Tiếng Việt