produktkategori

Produkttaggar

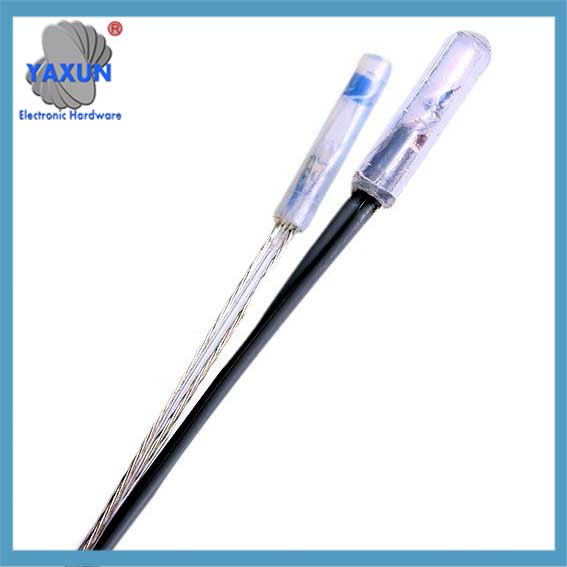

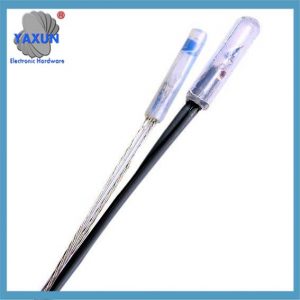

PT1000 temperature sensor used in disinfection cabinets

As a common household appliance, disinfection cabinets are widely used for food disinfection and health care in homes and commercial places. In disinfection cabinets, PT1000 temperature sensors are a very important device for accurately measuring and controlling the temperature inside the disinfection cabinet.

As a common household appliance, disinfection cabinets are widely used for food disinfection and health care in homes and commercial places. In disinfection cabinets, PT1000 temperature sensors are a very important device for accurately measuring and controlling the temperature inside the disinfection cabinet. With the improvement of health and safety awareness, the use of disinfection cabinets in homes and commercial places has become more and more common. Disinfection cabinets effectively eliminate bacteria and viruses through high-temperature sterilization to ensure the safety of food and tableware. Accurate temperature control is one of the important factors to ensure the normal operation of disinfection cabinets.

PT1000 temperature sensor is a thermistor sensor based on platinum material. It has high accuracy and stability and is often used in the field of high-precision temperature measurement. In disinfection cabinets, PT1000 temperature sensors are widely used to measure and control the temperature inside the disinfection cabinet.

Fördel 1: Accurate measurement

PT1000 temperature sensors have high measurement accuracy and can provide more accurate temperature measurement results than conventional sensors. This enables the disinfection cabinet to more accurately control and adjust the temperature of the heating element to ensure the effectiveness and safety of the disinfection process.

Fördel 2: Brett temperaturområde

PT1000 temperature sensor is suitable for a wide temperature range, usually from -200°C to +600°C. In the disinfection cabinet, the PT1000 temperature sensor can work stably in a higher temperature range, meeting the requirements of high temperature disinfection of the disinfection cabinet.

Fördel 3: Fast response

PT1000 temperature sensor has a fast response characteristic, which can quickly sense temperature changes and promptly feedback to the control system. This is especially important in the disinfection cabinet, because accurate control and adjustment of temperature are crucial to the disinfection effect.

Fördel 4: High temperature resistance

PT1000 temperature sensor is made of high temperature material and has good high temperature resistance. In the disinfection cabinet, the sensor needs to withstand the work in a high temperature environment, and the PT1000 temperature sensor can operate stably and maintain measurement accuracy for a long time.

In the disinfection cabinet, the PT1000 temperature sensor plays a key role in ensuring the accuracy and safety of the disinfection process. Its advantages include accurate measurement, wide temperature range, fast response and high temperature resistance. Disinfection cabinet manufacturers should select suitable PT1000 temperature sensors to ensure the best temperature control and disinfection effect of the disinfection cabinet. When selecting and using PT1000 temperature sensors, it is recommended to follow the manufacturer’s guidance and technical specifications to ensure its normal operation and long-term stability.

Kontakta oss

Väntar på ditt mejl, vi kommer att svara dig inom 12 timmar med värdefull information du behövde.

English

English العربية

العربية Български

Български 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά Magyar

Magyar Italiano

Italiano 日本語

日本語 한국어

한국어 Polski

Polski Português

Português Română

Română Русский

Русский Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Tiếng Việt

Tiếng Việt