Termistorer är speciella motstånd vars resistansvärde ändras med temperaturen. This type of resistor is widely used in various temperature detection, temperaturkontroll, thermal protection and other occasions. Understanding the basic principles of thermistors and how to judge their quality is very necessary for electronics enthusiasts or workers in related industries.

Vad är en termistor?

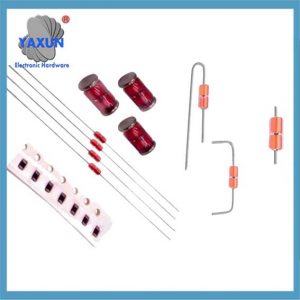

A thermistor is a resistor whose resistance value changes with temperature and is used for temperature detection, control and thermal protection. To judge whether a thermistor is good or bad, you need to check the appearance, resistance value, resistance change and response speed. When selecting and using thermistors, you need to consider the application scenarios and conditions, avoid harsh environments, and follow operating specifications.

Första, let’s understand the basic principles of thermistors. The resistance value of a thermistor changes with temperature, which makes it a very sensitive temperature sensor. According to the characteristics of the resistance value changing with temperature, thermistors can be divided into two types: positive temperature coefficient thermistors (PTC) and negative temperature coefficient thermistors (NTC). The resistance value of a positive temperature coefficient thermistor increases with increasing temperature, while the resistance value of a negative temperature coefficient thermistor decreases with increasing temperature. This resistance change characteristic enables thermistors to play an important role in temperature measurement, temperaturkontroll, overheat protection and other fields.

Så, how to judge the quality of a thermistor? We can judge it from the following aspects:

1. Check the appearance of the thermistor. A good thermistor should have a neat appearance, no damage, and no oxidation on the pins. If the thermistor is found to have damage or oxidation on the pins, it is likely that it has been damaged or aged.

2. Use a multimeter to detect the resistance of the thermistor. At room temperature, the resistance of the thermistor detected by a multimeter should be consistent with the nominal value. If the resistance is too large or too small, it is likely that the thermistor is damaged or has poor performance.

3. Detect the change in the resistance of the thermistor by heating. For a negative temperature coefficient thermistor (NTC), its resistance should decrease when the temperature rises. For positive temperature coefficient thermistors (PTCs), their resistance should increase when the temperature rises. If the resistance change of the thermistor does not conform to this rule during the heating process, it is likely that the thermistor is damaged or has poor performance.

4. Check the response speed of the thermistor. A good thermistor should have a fast response speed, som är, when the temperature changes, its resistance can react quickly. If the thermistor responds too slowly, it may be that its performance is poor or aging.

In summary, judging the quality of thermistors requires comprehensive consideration of appearance, resistance, resistance change, and response speed. For different types of thermistors, the judgment method is also different. In actual applications, we also need to select the appropriate type and model of thermistor according to the specific application scenarios and requirements to ensure its normal operation and long-term stability.

Dessutom, we also need to pay attention to the use environment and conditions of the thermistor. Till exempel, thermistors should avoid being used in harsh environments such as high temperature, high humidity, and strong magnetic fields to avoid affecting their performance and stability. Samtidigt, when installing and using thermistors, we should also follow relevant operating specifications and safety requirements to ensure that they work safely and reliably.

In short, understanding the basic principles of thermistors and how to judge their quality is very important for electronics enthusiasts or workers in related industries. By reasonably selecting and using thermistors, we can better realize functions such as temperature detection, temperaturkontroll, and thermal protection, providing strong guarantees for the safe and stable operation of various electronic devices.

English

English العربية

العربية Български

Български 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Nederlands

Nederlands Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά Magyar

Magyar Italiano

Italiano 日本語

日本語 한국어

한국어 Polski

Polski Português

Português Română

Română Русский

Русский Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Tiếng Việt

Tiếng Việt