Danh mục sản phẩm

- cầu chì nhiệt 32

- cầu chì gắn trên bề mặt 12

- nhiệt điện trở 36

- Giá đỡ cầu chì gắn PCB 27

- Dây nịt dây điện 6

- Giá đỡ cầu chì lưỡi 17

- máy điều nhiệt 50

- Cầu chì điện 24

- Cảm biến nhiệt độ ô tô 7

- Bộ ngắt mạch nhiệt 22

- Hộp đựng cầu chì 36

- Cảm biến nhiệt độ 75

- Công tắc nhiệt 68

- Cầu chì ô tô 20

- Cầu chì chốt xuống 8

Thẻ sản phẩm

Đầu dò cảm biến nhiệt độ RTD PT100 có cáp

Cảm biến điện trở nhiệt Platinum là gì?

Một RTD (Máy dò nhiệt độ kháng) là điện trở nhiệt bạch kim có điện trở thay đổi khi nhiệt độ thay đổi. Điện trở của nó tăng khi nhiệt độ cảm biến tăng. Mối quan hệ giữa điện trở và nhiệt độ được biết rõ và có thể lặp lại theo thời gian. RTD là một thiết bị thụ động. Nó không tự tạo ra đầu ra. Thiết bị điện tử bên ngoài có thể được sử dụng để đo điện trở cảm biến bằng cách truyền một dòng điện nhỏ qua cảm biến để tạo ra điện áp. Tiêu biểu 1 mA hoặc ít hơn đo dòng điện, tối đa 5 ma, không có nguy cơ tự sưởi ấm.

Máy dò nhiệt độ điện trở nhiệt bạch kim (PT100 RTD) là một cảm biến được sử dụng để đo nhiệt độ bằng cách thay đổi điện trở theo nhiệt độ. RTD PT100 được thiết kế với phần tử nhiệt độ cơ bản và lắp ráp đầu dò và dây dẫn hoàn chỉnh. Các đầu dò RTD được gọi là này bao gồm một nguyên tố kháng nhiệt bạch kim, một vỏ bọc hoặc nhà ở, Epoxy hoặc chất làm đầy vật liệu, Mở rộng khách hàng tiềm năng, và đôi khi là một đầu nối hoặc chấm dứt. Các vật liệu cảm biến khác nhau có thể được sử dụng dựa trên các yêu cầu của khách hàng về khả năng tương thích vật liệu, Độ chính xác và phạm vi đo lường. Bộ dụng cụ tiêu chuẩn và thiết kế tùy chỉnh cung cấp sự linh hoạt để thiết kế cảm biến nhiệt độ RTD phù hợp nhất cho nhiều ứng dụng khác nhau.

Các cảm biến và đầu dò nhiệt độ RTD PT100 có thể được tích hợp vào nhiều ứng dụng khác nhau trong nhiều ngành công nghiệp. Các cảm biến nhiệt độ này được chứng nhận bởi nhiều cơ quan để hoạt động trên các thành phần áp suất gắn trên tàu; Họ cũng có thể hoạt động trong môi trường khắc nghiệt và nguy hiểm. Phạm vi rộng của các tùy chọn sản phẩm cảm biến nhiệt độ của chúng tôi giải quyết các nhu cầu cảm biến cụ thể của các ứng dụng OEM yêu cầu bao gồm cả y tế, Không gian vũ trụ, Ô tô, thiết bị, Thiết bị gia dụng, Điều khiển động cơ và hệ thống làm lạnh và HVAC.

RTD PT100 dung sai tiêu chuẩn

RTD được xây dựng thành một số đường cong và dung sai được tiêu chuẩn hóa. Đường cong được sử dụng phổ biến nhất được sử dụng là “TỪ” đường cong. Đường cong này mô tả đặc tính điện trở và nhiệt độ của bạch kim với 100 cảm biến ohm, dung sai tiêu chuẩn hóa, và phạm vi nhiệt độ có thể đo được.

Tiêu chuẩn DIN quy định điện trở cơ bản là 100 ohm ở 0°C và hệ số nhiệt độ là 0.00385 ohm/ohms/°c. Đầu ra danh nghĩa của cảm biến DIN RTD như sau:

DIN RTD có ba cấp dung sai tiêu chuẩn. Các dung sai này được xác định như sau:

DIN loại A: ±(0.15 + 0.002 |T|°C)

DIN loại B: ±(0.3 + 0.005 |T|°C)

DIN loại C: ±(1.2 + 0.005 |T|°C)

0°C/ôm

0: 100.00

10: 103.90

20: 107.79

30: 111.67

40: 115.54

50: 119.40

60: 123.24

70: 127.07

80: 130.89

90: 134.70

100: 138.50

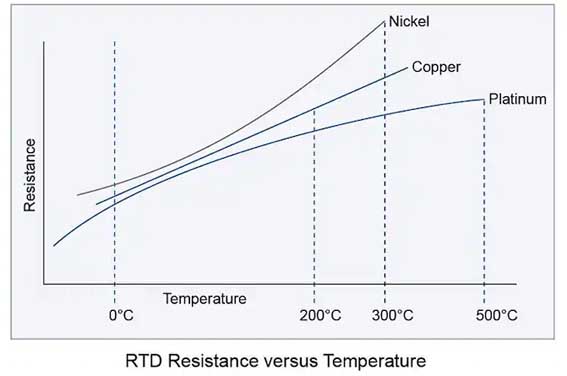

Loại thành phần RTD

Khi xác định loại phần tử RTD, đầu tiên hãy xem xét dụng cụ được sử dụng để đọc cảm biến. Chọn loại thành phần tương thích với đầu vào cảm biến của thiết bị. Cho đến nay, RTD được sử dụng phổ biến nhất là 100 ohm bạch kim với hệ số nhiệt độ là 0.00385.

Loại thành phần Điện trở cơ sở (ôm) TCR (ohm/ohms/°C)

Bạch kim 100 ohm ở 0°C .00385

Bạch kim 100 ohm ở 0°C .00392

Bạch kim 100 ohm ở 0°C .00375

Niken 120 ohm ở 0°C .00672

đồng 10 ohm ở 25°C .00427

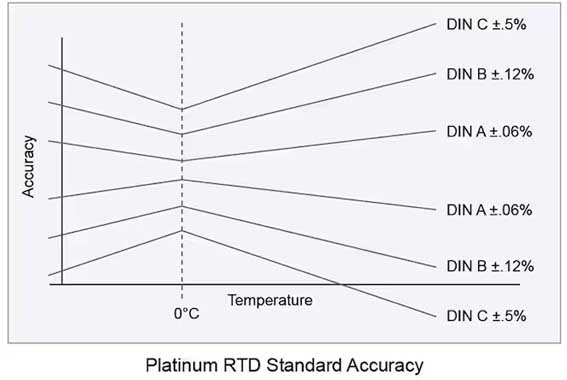

độ chính xác RTD

Thứ hai, xác định độ chính xác đo cần thiết. Độ chính xác là sự kết hợp của dung sai điện trở cơ sở (dung sai điện trở ở nhiệt độ hiệu chuẩn) và hệ số nhiệt độ dung sai điện trở (dung sai độ dốc đặc trưng). Bất kỳ nhiệt độ nào cao hơn hoặc thấp hơn mức này sẽ có dải dung sai rộng hơn hoặc độ chính xác kém hơn (xem hình bên dưới). Nhiệt độ hiệu chuẩn được sử dụng phổ biến nhất là 0°C.

Cảm biến RTD PT100 có sẵn ở nhiều cấu hình dây dẫn khác nhau. Cấu hình phổ biến nhất là cấu hình ba dây dẫn một phần tử. Sơ đồ cấu hình dây dẫn có sẵn được hiển thị bên dưới:

Cảm biến hai dây PT100/PT1000 thường được sử dụng trong các ứng dụng mà độ chính xác không quan trọng. Cấu hình hai dây cho phép thực hiện kỹ thuật đo đơn giản nhất, nhưng vốn có những điểm không chính xác do điện trở của dây dẫn cảm biến. Trong cấu hình hai dây, không thể bù trực tiếp điện trở dây dẫn làm tăng độ lệch trong phép đo điện trở.

Cảm biến ba dây PT100/PT1000 có vòng bù có thể loại bỏ điện trở dây dẫn trong quá trình đo. Với cấu hình này, bộ điều khiển/thiết bị đo có thể thực hiện hai phép đo. Đối với lần đo đầu tiên, đo tổng điện trở của cảm biến và dây nối. Trong lần đo thứ hai, đo điện trở của điện trở vòng bù. Điện trở thực tế được xác định bằng cách trừ đi điện trở vòng bù khỏi tổng điện trở. Cảm biến ba dây là cấu hình phổ biến nhất và cung cấp sự kết hợp tốt giữa độ chính xác và sự thuận tiện.

Cảm biến nhiệt độ PT100

Đầu dò cảm biến PT100

Điện trở RTD so với nhiệt độ

Độ chính xác tiêu chuẩn RTD bạch kim

Cấu hình cảm biến bốn dây PT100/PT1000. Trong khi kỹ thuật này chính xác hơn, Nhiều bộ điều khiển công nghiệp/thiết bị đo không thể đạt được các phép đo bốn dây thực sự.

Sự chuyển đổi từ cảm biến dẫn đến hệ thống dây điện trường thường được thực hiện tại đầu nối kết nối với cảm biến. Các khối đầu cuối được cung cấp để kết nối dễ dàng.

Đo nhiệt độ bằng máy dò nhiệt độ điện trở thực sự là đo điện trở. Một cây cầu lúa mì không cân bằng thường được sử dụng để đo điện trở. Khi đo điện trở của phần tử cảm biến, Tất cả các yếu tố bên ngoài phải được giảm thiểu hoặc bù đắp để có được việc đọc chính xác.

Một nguyên nhân chính của lỗi có thể là sự kháng cự của các khách hàng tiềm năng, đặc biệt là trong cấu hình hai dẫn.

Điện trở được nối tiếp với phần tử cảm biến, Vì vậy, việc đọc là tổng của yếu tố cảm biến và điện trở chì. RTD hai lãnh đạo có thể được sử dụng khi điện trở của phần tử cảm biến cao và điện trở của khách hàng tiềm năng thấp.

Tuy nhiên, Khi sức đề kháng của khách hàng tiềm năng tương đối cao, nó phải được bồi thường. Bồi thường có sẵn trong cấu hình ba dẫn. Như thể hiện trong sơ đồ ba dẫn, Một mặt của nguồn điện được kết nối với một bên của RTD đến L3. Điều này đặt L1 và L2 ở phía đối diện của cây cầu, Vì vậy, họ hủy bỏ nhau và không có tác dụng đối với điện áp đầu ra cầu.

Nên sử dụng kết nối ba lãnh đạo cho RTD, Đặc biệt nếu điện trở phần tử cảm biến thấp, Trường hợp một điện trở chì nhỏ có thể có tác động lớn đến độ chính xác của việc đọc.

Liên hệ với chúng tôi

Đang chờ email của bạn, chúng tôi sẽ trả lời bạn trong vòng 12 giờ với thông tin có giá trị bạn cần.

English

English Afrikaans

Afrikaans العربية

العربية বাংলা

বাংলা bosanski jezik

bosanski jezik Български

Български Català

Català 粤语

粤语 中文(简体)

中文(简体) 中文(漢字)

中文(漢字) Hrvatski

Hrvatski Čeština

Čeština Nederlands

Nederlands Eesti keel

Eesti keel Suomi

Suomi Français

Français Deutsch

Deutsch Ελληνικά

Ελληνικά हिन्दी; हिंदी

हिन्दी; हिंदी Magyar

Magyar Bahasa Indonesia

Bahasa Indonesia Italiano

Italiano 日本語

日本語 한국어

한국어 Latviešu valoda

Latviešu valoda Lietuvių kalba

Lietuvių kalba македонски јазик

македонски јазик Bahasa Melayu

Bahasa Melayu Norsk

Norsk پارسی

پارسی Polski

Polski Português

Português Română

Română Русский

Русский Cрпски језик

Cрпски језик Slovenčina

Slovenčina Slovenščina

Slovenščina Español

Español Svenska

Svenska ภาษาไทย

ภาษาไทย Türkçe

Türkçe Українська

Українська اردو

اردو Tiếng Việt

Tiếng Việt